Tubing drilling device

A perforating device and tubing technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of tubing strength reduction, perforating gun perforating precision can not be accurately controlled, etc., to achieve precise control of drilling Accuracy, reducing operating costs and construction risks, and improving the success rate of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

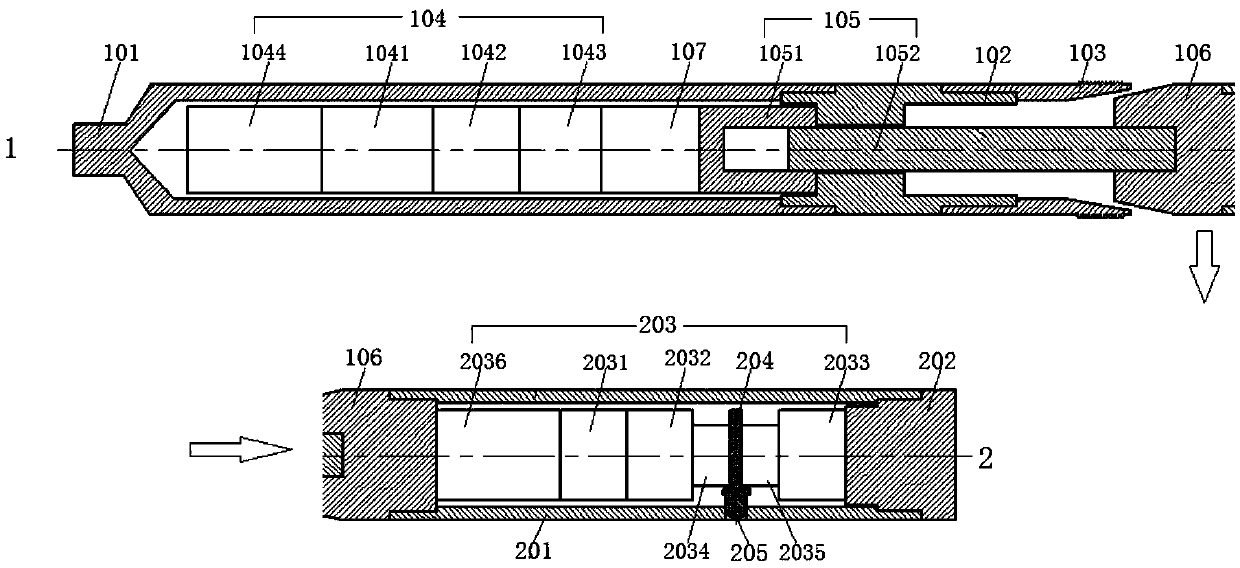

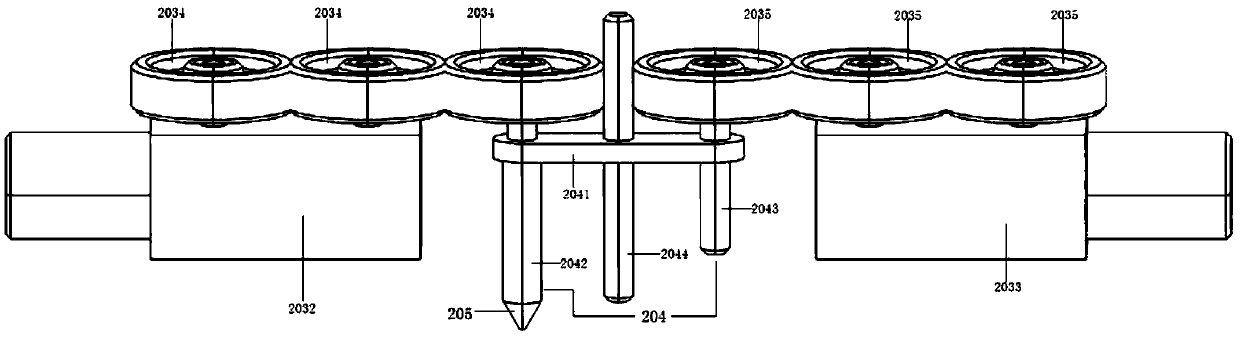

[0052] The embodiment of the present invention provides a oil pipe drilling device, as attached figure 1 As shown, the oil pipe drilling device includes: an anchoring mechanism 1 and a drilling mechanism 2 . Wherein, the anchoring mechanism 1 includes: an upper sleeve 101 connected in sequence from top to bottom, an upper joint 102, a slip 103, an upper driving part 104 located inside the upper sleeve 101, and an upper shaft connected to the upper driving part 104. The moving part 105, the cone 106 connected with the upper driving part 105. Wherein, the upper driving member 104 drives the cone 106 to move up and down through the upper transmission member 105 , so that the cone 106 enters or disengages from the slips 103 . The punching mechanism 2 includ

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap