Parallel pair cable with continuous characteristic impedance

A characteristic impedance and continuity technology, applied in the direction of insulated cables, twisted/quad-stranded cables, cables, etc., can solve problems such as discontinuity of cable characteristic impedance and influence of cable signal integrity, and achieve To achieve the effect of continuity and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example

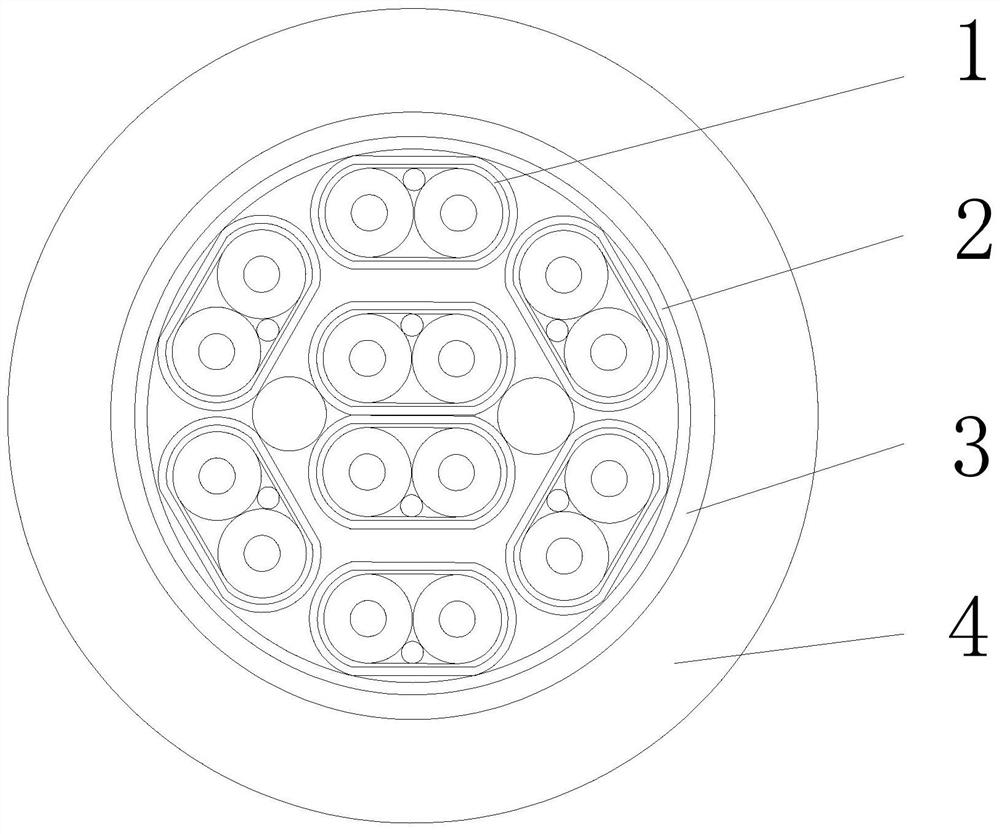

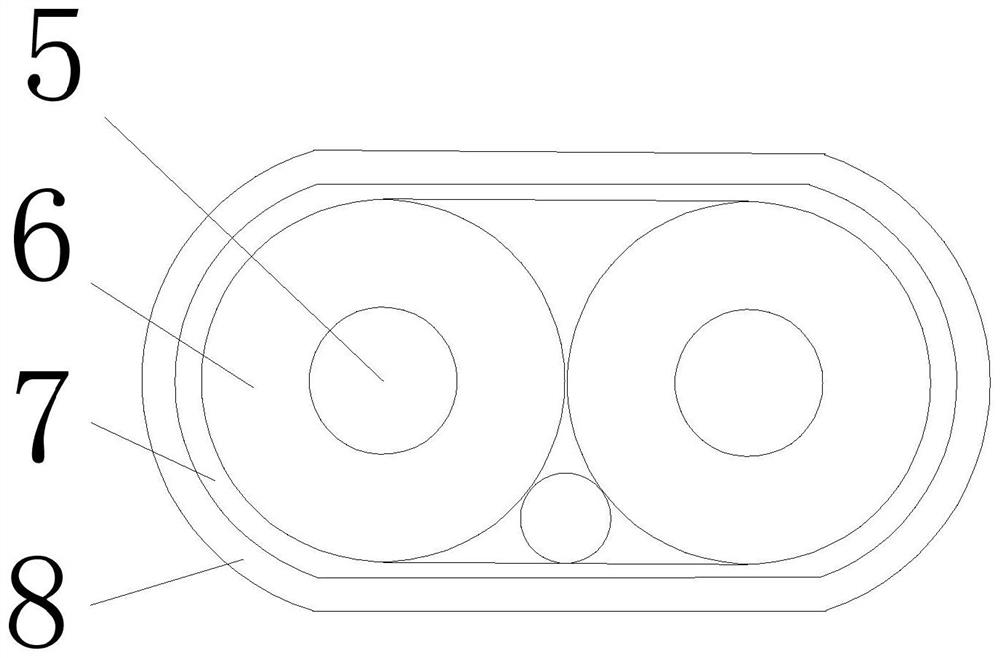

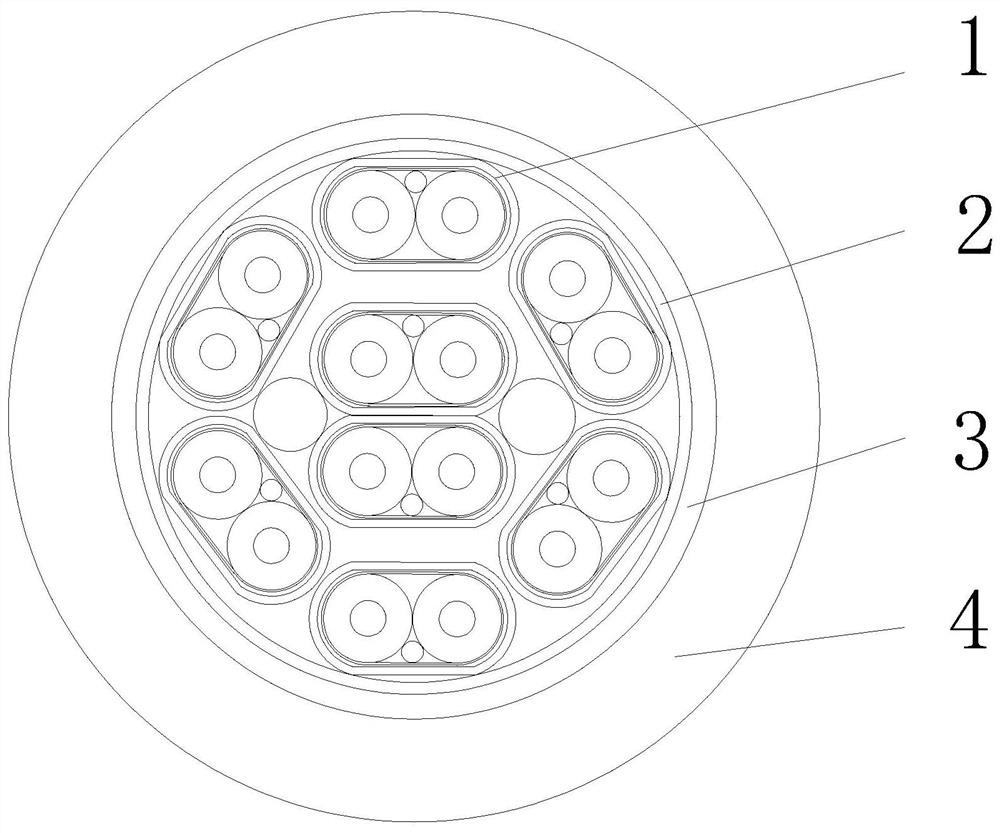

[0025] like figure 1 with figure 2 As shown, a 28AWG (1 / 0.0.32) conductor is used, and the insulating layer 6 is a PE structure as an example.

[0026] When the cable is shielded, the characteristic impedance:

[0027] ε is the dielectric constant of the insulating medium, and a is the outer diameter of the insulating layer 6, and D is the outer diameter of the center conductor 5;

[0028] Known, D = 0.32mm, characteristic impedance = 100 ohms, ε = 2.3;

[0029] The insulating outer diameter A = 1.135 mm is calculated from the above formula to 100 ohms.

[0030] When welding is performed, the third shield layer 7 is removed, and the characteristic impedance of the portion:

[0031] ε is the dielectric constant of the insulating medium, and a is the outer diameter of the insulating layer 6, and D is the outer diameter of the center conductor 5;

[0032] It is known, D = 0.32mm, A = 1.23, ε = 2.6;

[0033] The PCB pad portion (remove the third shield 7 section) c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap