Insulating pull rod characteristic testing device

A technology of insulating tie rods and characteristic testing, which is applied in the direction of testing dielectric strength, etc., can solve the problems of low reliability of insulation performance test results of insulating tie rods, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

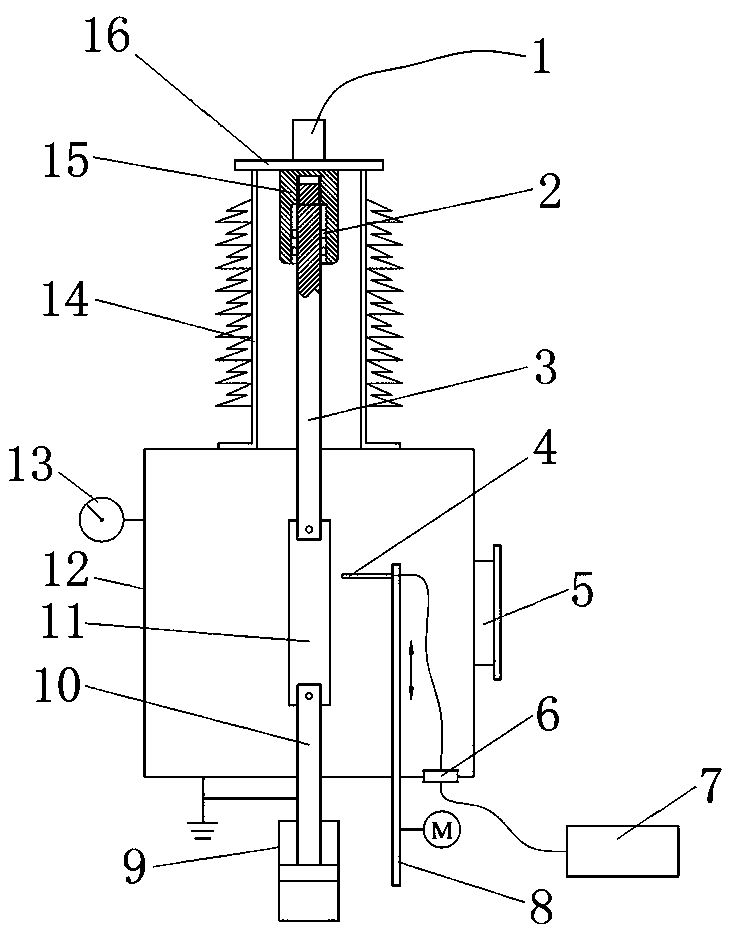

[0021] A specific embodiment of the insulating rod characteristic testing device of the present invention, such as figure 1 As shown, the testing device for the characteristics of the insulating rod in this embodiment can simulate the actual working conditions of the insulating rod, and can realize the test of the insulation performance of the insulating rod under simultaneous voltage loading and force loading.

[0022] The insulating rod characteristic testing device includes a closed air chamber 12, which is a closed cylinder. In specific use, the closed air chamber 12 can be installed on a movable support. And the gas in the closed gas chamber 12 can be sulfur hexafluoride gas, also can be other test gases. A pressure gauge 13 is installed on the closed air chamber 12 to measure the air pressure in the closed air chamber 12. A filling and deflation port

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap