Abrasive tool forming material and preparation method thereof as well as abrasive tool and preparation process thereof

A molding material and abrasive technology, applied in the direction of abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems that affect the molding process, the molding materials of abrasive tools are easy to agglomerate, and the production cycle is prolonged, so as to ensure product quality and avoid adverse effects , the effect of moisture content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0061] The preparation method of the consolidation agent, typically but not restrictively, includes the following steps:

[0062] Mix the paraffin and beeswax uniformly to obtain a mixture A, mix the tallow and lanolin evenly to obtain a mixture B, and add the mixture B to the mixture A to obtain a consolidation agent.

[0063] The specific raw material composition of the ceramic bond directly affects the bonding of the abrasive molding material, and also affects the subsequent preparation process of the abrasive tool, as well as the strength, hardness, self-sharpness and service life of the final abrasive.

[0064] As an optional embodiment of the present invention, the ceramic bond is mainly made of the following raw materials in weight percentage:

[0065] Clay 20-55%, potash feldspar 25-65%, talc 2-20% and flux 0-25%, the sum of the weight percentage of each raw material of the ceramic bond is 100%.

[0066] Clay is a kind of hydrous aluminosilicate mineral, mainly including kaolinite,

Example Embodiment

[0075] As an optional embodiment of the present invention, the main adhesive includes any one or a combination of at least two of lithium silicate, potassium silicate, or sodium silicate;

[0076] Lithium silicate, potassium silicate and sodium silicate can all be used as the main adhesive. Above 400℃, the green body can be guaranteed to have a certain strength, and the green body will not deform until it is fired at a higher temperature.

[0077] In addition, the lithium silicate has a low thermal expansion coefficient and is not easy to burst when the temperature is lowered, so that the bursting waste rate of the abrasive tool is low. At the same time, it can increase the viscosity of the vitrified liquid at 900°C and reduce the deformation of the high-temperature blank.

[0078] As an optional embodiment of the present invention, the auxiliary adhesive is a dextrin liquid, and the viscosity of the dextrin liquid is 1.5-2.7 centipoise.

[0079] The typical but non-limiting viscosity of

Example Embodiment

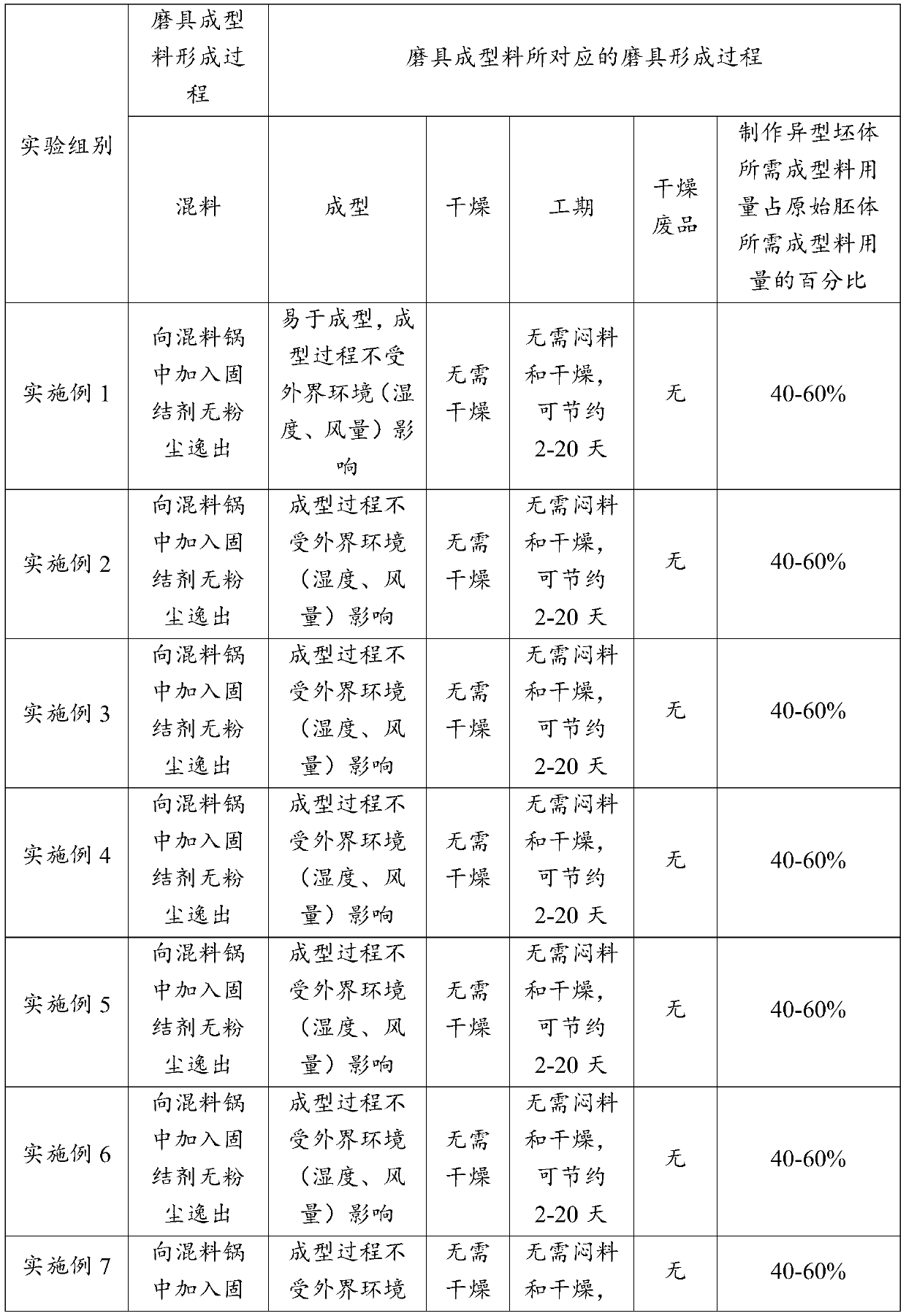

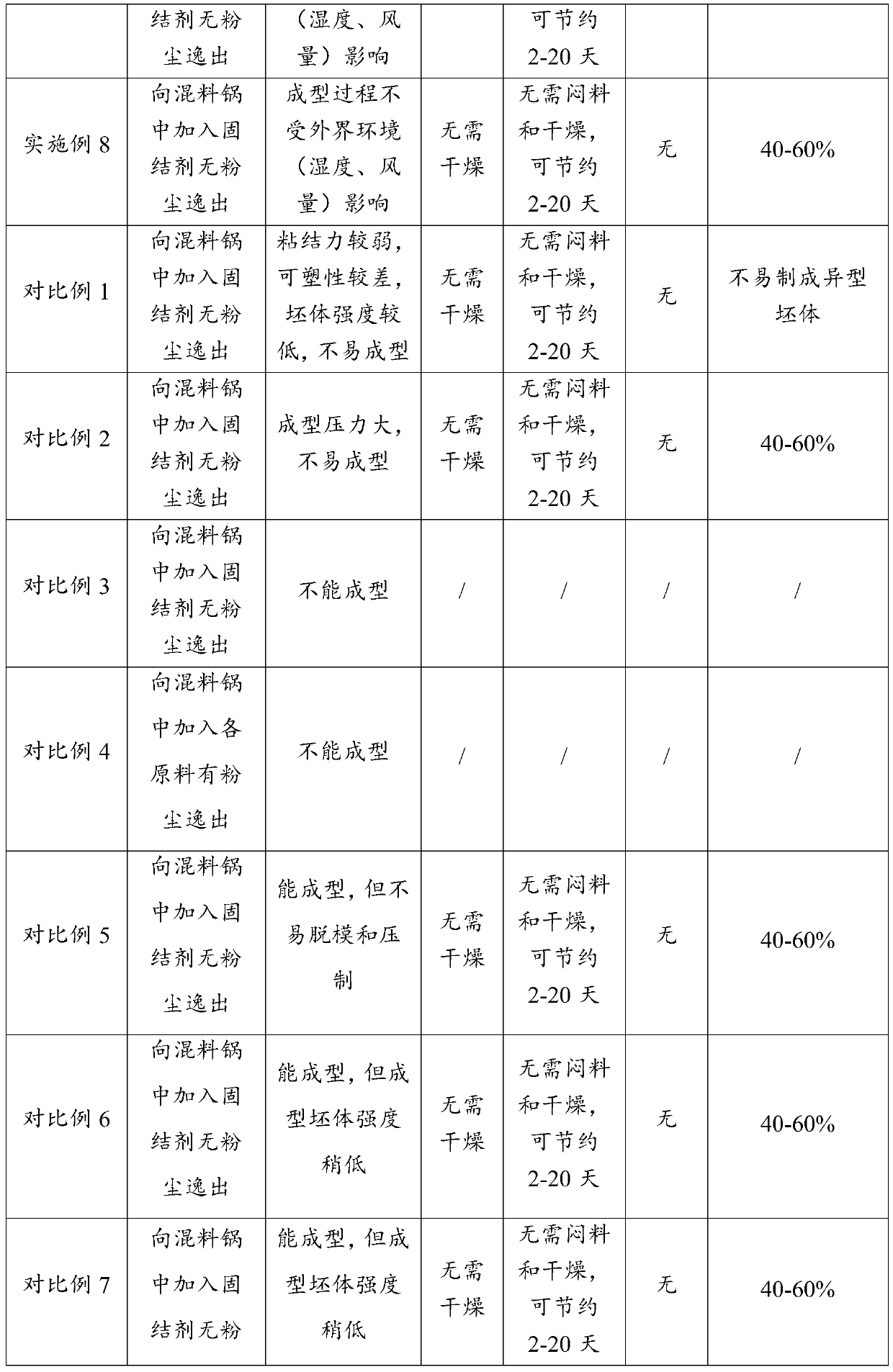

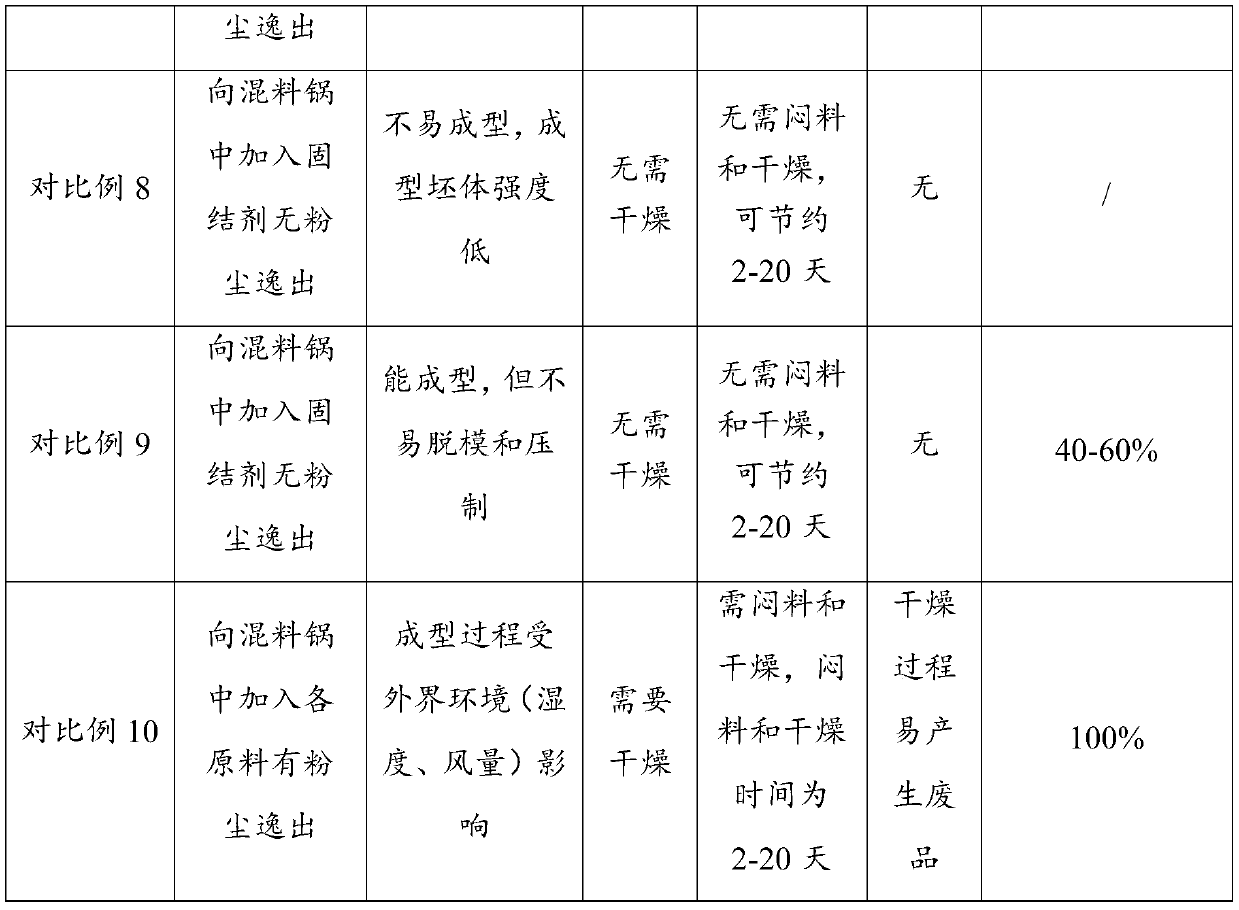

[0104] Example 1

[0105] The embodiment of the present invention provides a molding material for abrasive tools, which is mainly made of the following raw materials by weight percentage:

[0106] Corundum abrasive 86%, ceramic bond 7.5%, consolidation agent 5.25%, main binder sodium silicate 0.95% and auxiliary binder dextrin 0.3%;

[0107] Among them, the consolidation agent is paraffin, beeswax, tallow and lanolin, the weight ratio of paraffin, beeswax, tallow and lanolin is 42.5:2.3:0.05:0.016; the viscosity of the dextrin liquid is 2.0 centipoise;

[0108] The ceramic bond is mainly made of the following raw materials in weight percentage: 20% clay, 60% potash feldspar, 8% talc and 12% high boron glass powder. The total weight percentage of each raw material of the ceramic bond is 100%.

[0109] The preparation method of the aforementioned abrasive tool molding material includes the following steps:

[0110] (a) Put the corundum abrasive in the mixing pot and heat it to 60℃ to uniform

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap