Double-wire guardrail mesh electric resistance welding machine

A fence mesh and sheet resistance technology, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of slow manual wire threading and welding work, low mesh strength, and irregular mesh welding. The effect of improving the aesthetics and strength of the mesh, improving practicability and reliability, and improving the uniformity of solder joint distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

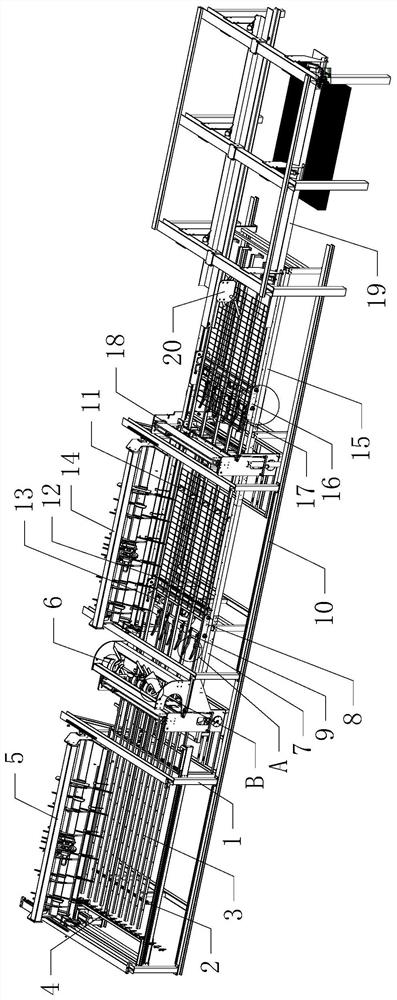

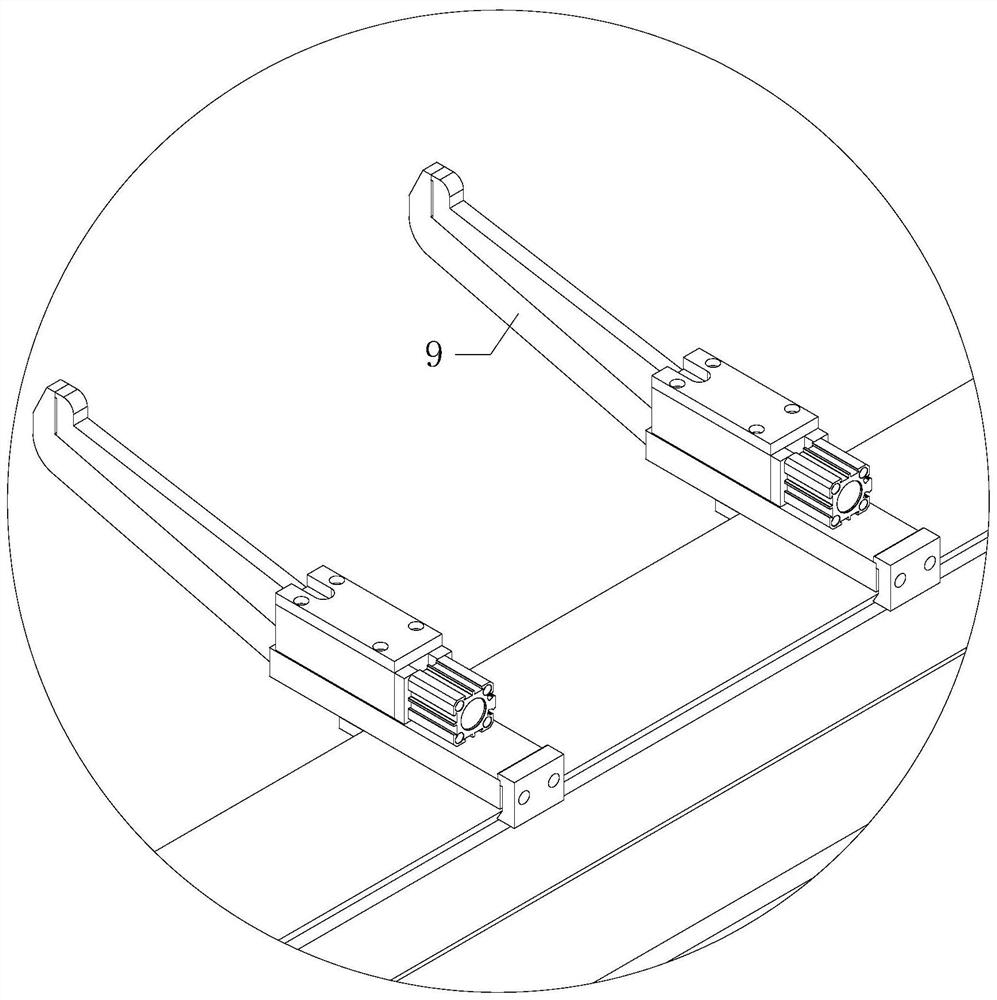

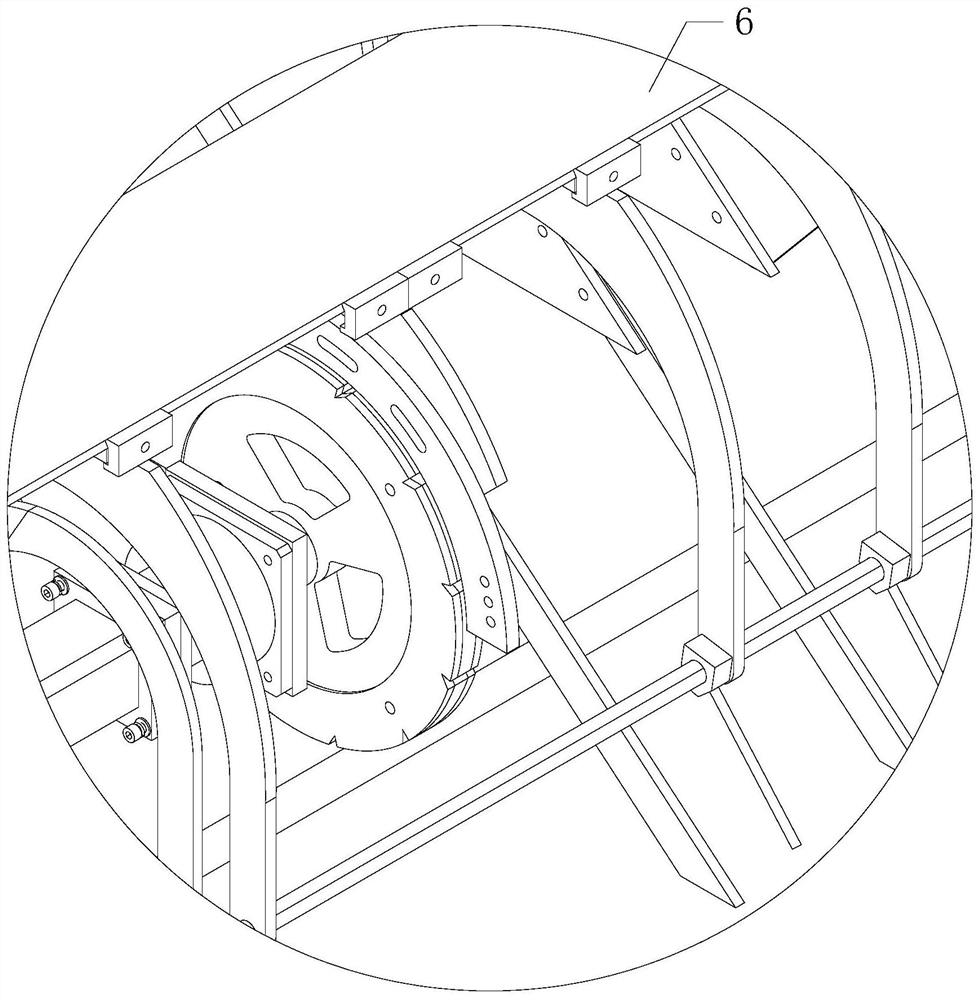

[0016] Such as Figure 1 to Figure 3 As shown, the double wire guardrail mesh resistance welding machine of the present invention, when it is working, places the longitudinal wire and the horizontal wire in the first main welding machine, and simultaneously places another group of longitudinal wires in the second main welding machine , through the welding mechanism 18 on the first main welding machine, the longitudinal wire and the horizontal wire are welded successively to form a mesh, and the welded mesh is sent to the second main welding machine, and the second main welding machine The longitudinal wires are arranged on the mesh and are subjected to secondary welding by t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap