Fluid storage supplementing device and hydraulic system

A fluid and hydraulic pump technology, used in fluid pressure actuation devices, servo motors, servo motor components, etc., can solve problems such as unsuitability for hydraulic systems and oil leakage, achieve light weight, ensure stable working conditions, and improve working life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0050] Example 1

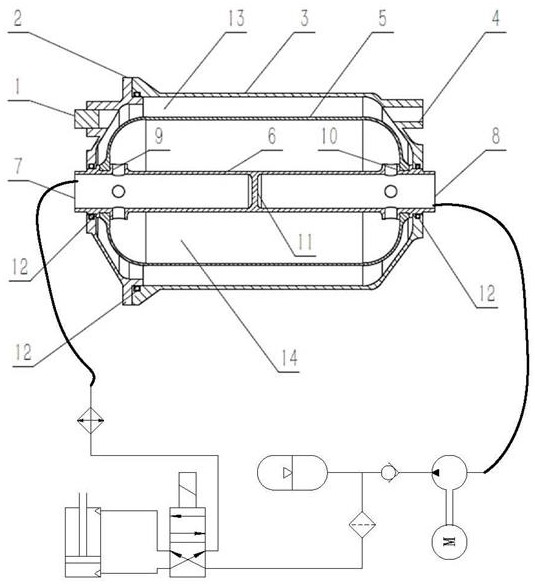

[0051] Figure 2 It is an open hydraulic system with a valve-controlled hydraulic cylinder. In this system, the traditional hydraulic oil tank is replaced by the device of the present invention. The oil return of the hydraulic system is connected to the oil return port 7 of the device, and the oil suction port of the hydraulic pump is connected to the oil suction port 8 of the device. The return oil of the hydraulic system enters the soft bag 5 of the device through the return port 7 for storage. At the same time, the hydraulic pump sucks the fluid from the soft bag 5. Because the soft bag 5 isolates the fluid from the outside air, the hydraulic pump can stably suck the fluid from the system no matter how the posture of the system swings upside down.

Example Embodiment

[0052] Example 2

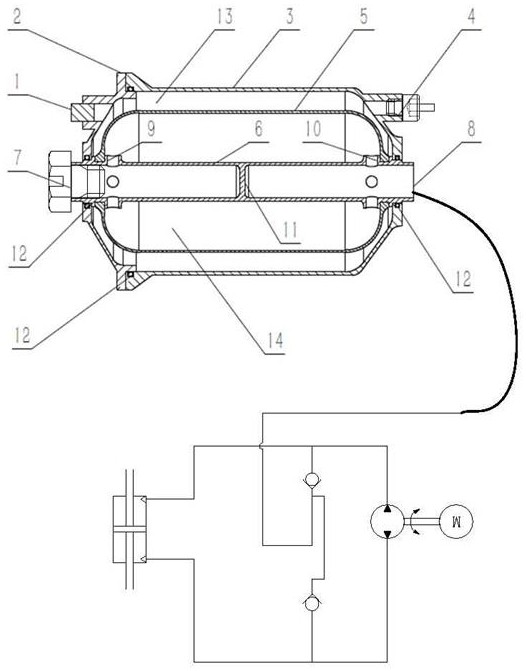

[0053] Figure 3 As a closed hydraulic system, the hydraulic pump drives the hydraulic cylinder to expand or contract through bidirectional rotation. This device replaces the function of oil pump to supplement oil to the closed hydraulic system. When the oil return port 7 of the device is in operation, it is blocked by a cap or plug to prevent the fluid from leaking. A one-way valve needs to be installed on the vent hole 4, and a certain amount of compressed gas is injected into the outer cavity 13 through this one-way valve. The compressed gas forms a certain pressure in the outer cavity 13, and the pressure squeezes the fluid into the oil suction port 8 through the soft bag 5, forming a certain pressure in the oil suction port 8. When the closed hydraulic system loses a certain amount of fluid due to leakage during operation, resulting in the pressure in the hydraulic system pipeline being lower than that in the oil suction port 8, the fluid stored in the device

Example Embodiment

[0054] Example 3

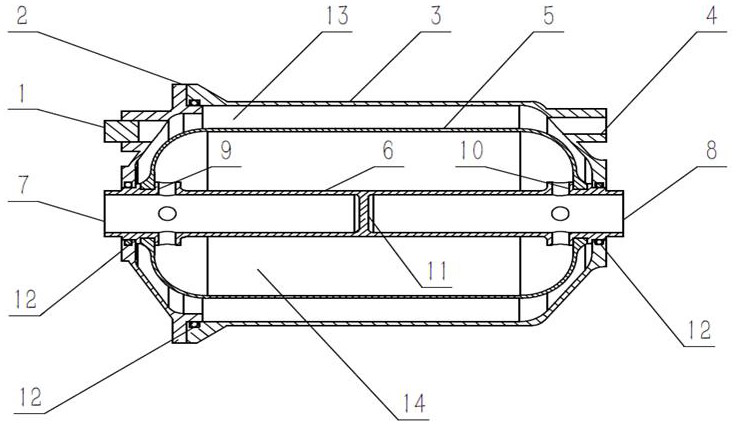

[0055] Figure 4 for Figure 1 Compared with the technical scheme introduced before, the central pipeline 6 is a straight pipeline, and there is no partition 11 between the oil return port 7 and the oil suction port 8. In the original scheme, the function of the baffle 11 is to extend the distance of the fluid from the oil return port 7 to the oil suction port 8, which helps the fluid to separate out the gas dissolved in it. However, if the working condition of the hydraulic system is mild, the amount of gas dissolved in the fluid is small, or the device is used for oil replenishment, the partition 11 may not exist.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap