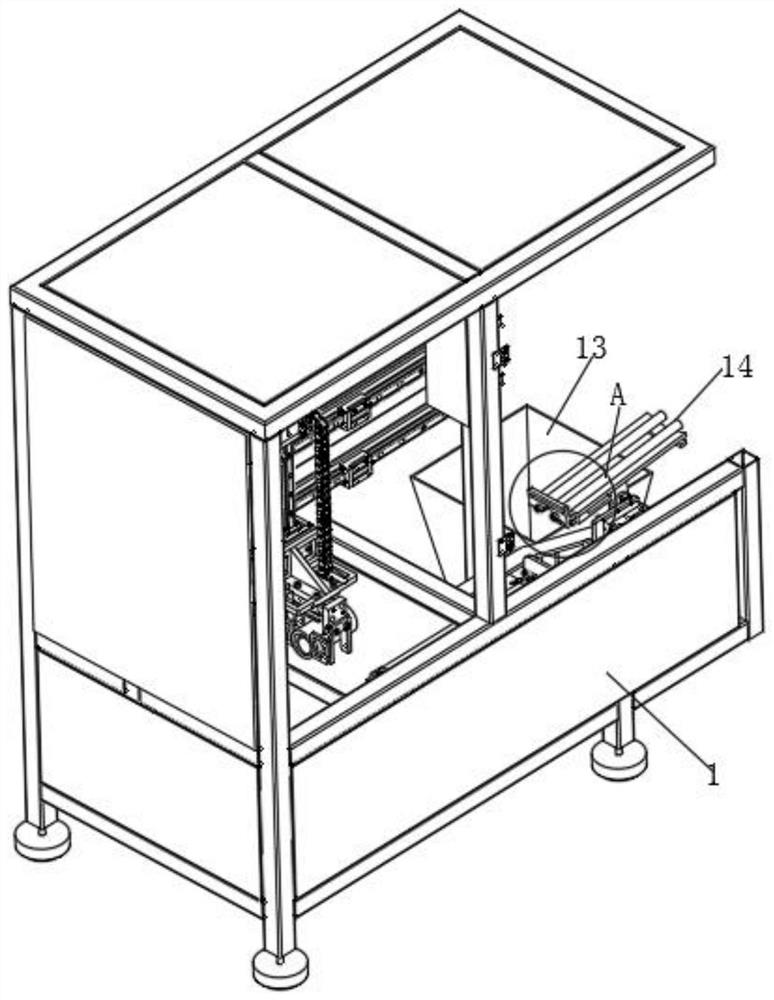

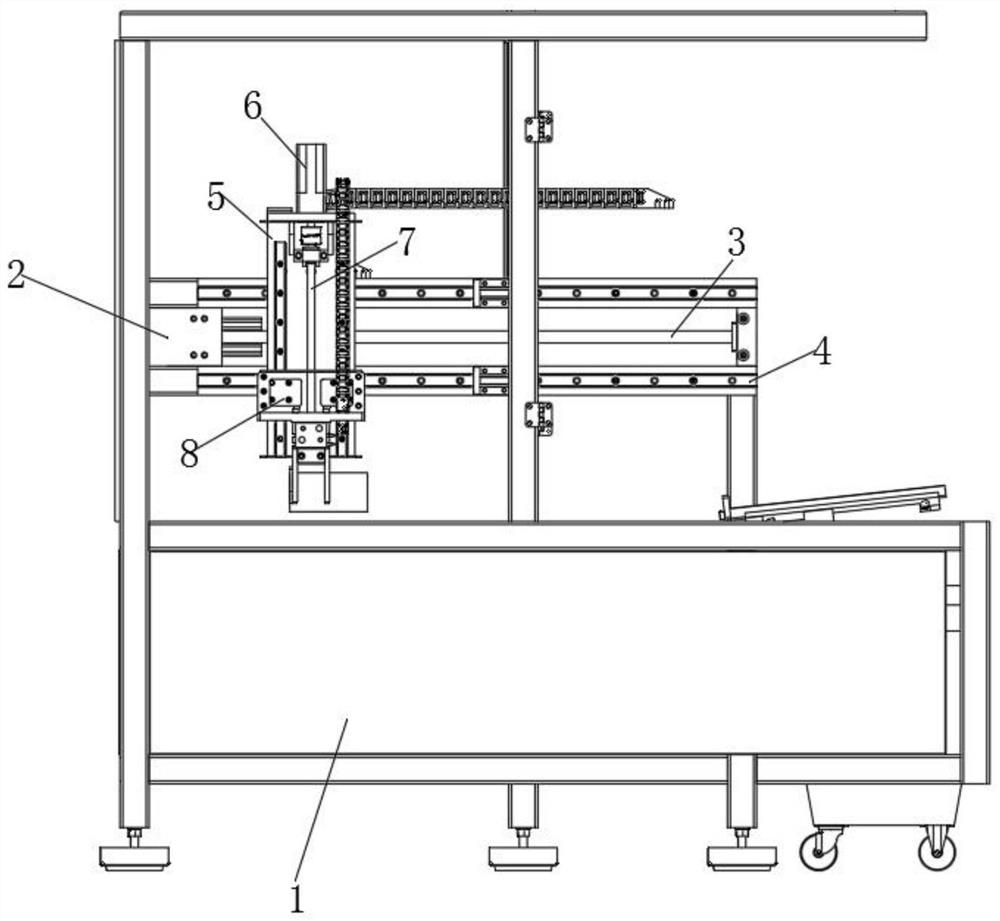

Construction steel bar machining device

A processing device and a technology for building steel bars, which are applied in the field of construction engineering, can solve problems such as unloading of steel bars, collision of steel bars, damage of steel bars, etc., achieve fast and convenient automatic unloading operations, and avoid damage to steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach

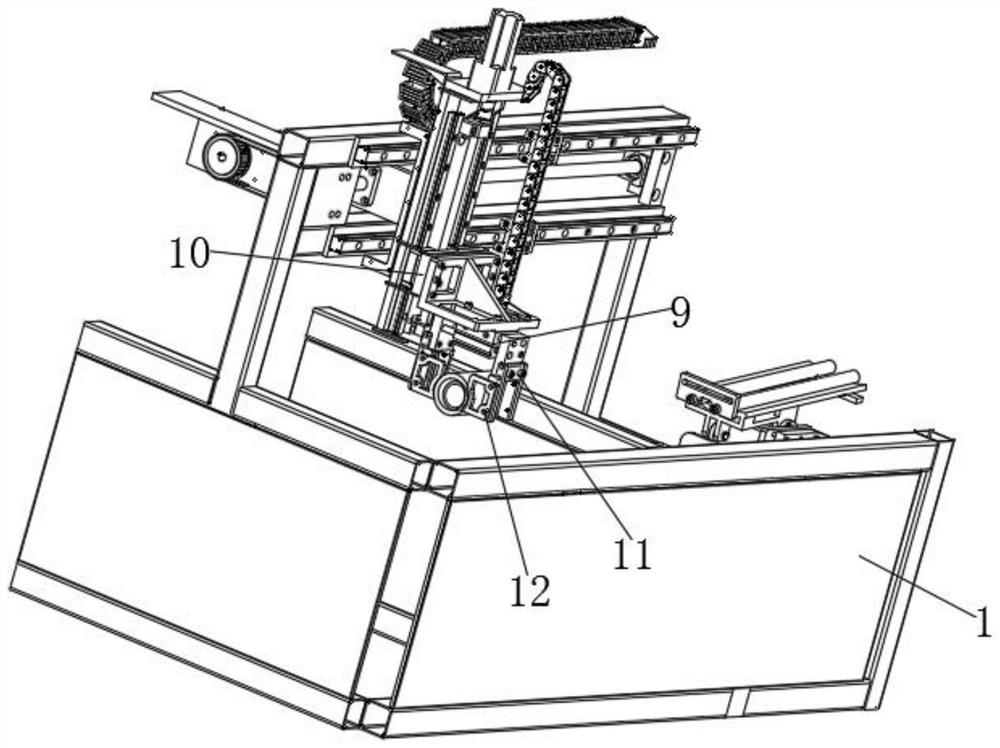

[0033] As an embodiment of the present invention, the placement frame 20 includes a bottom plate and two sloping plates, and the top sides of the two sloping plates are installed on the top side of the bottom plate at 135°, and wheels are installed at the bottom of the bottom plate and on both sides of the discharge chute 24. seat, and rollers are installed in the wheel seat, the limiter 16 includes a horizontal plate and a lifting plate, and the bottom side of the lifting plate and the bottom side of the horizontal plate are 150°, the horizontal plate is connected with the inner wall of the frame 1, and the rollers of the wheel seat are located on the horizontal plate On the top side, the placing frame 20 is in a horizontal state, and the working elongation of the second air pressure rod 15 drives the translation frame 19 to slide on the second slide rail 21. At this time, the rollers move along the limiter 16. Frame 20 rotates on rotating shaft 17 by bearing seat 18, and this mo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap