Automobile welding position polishing and cleaning device

A technology for cleaning devices and welds, which is applied in the direction of grinding drive devices, abrasive surface adjustment devices, grinding/polishing safety devices, etc. It can solve problems such as unstable placement, difficult cleaning, and different shapes of weldments to achieve grinding Convenient and efficient, improve the grinding effect, improve the stability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023]Example 1:

[0024]SeeFigure 1-6, The present invention provides a technical solution:

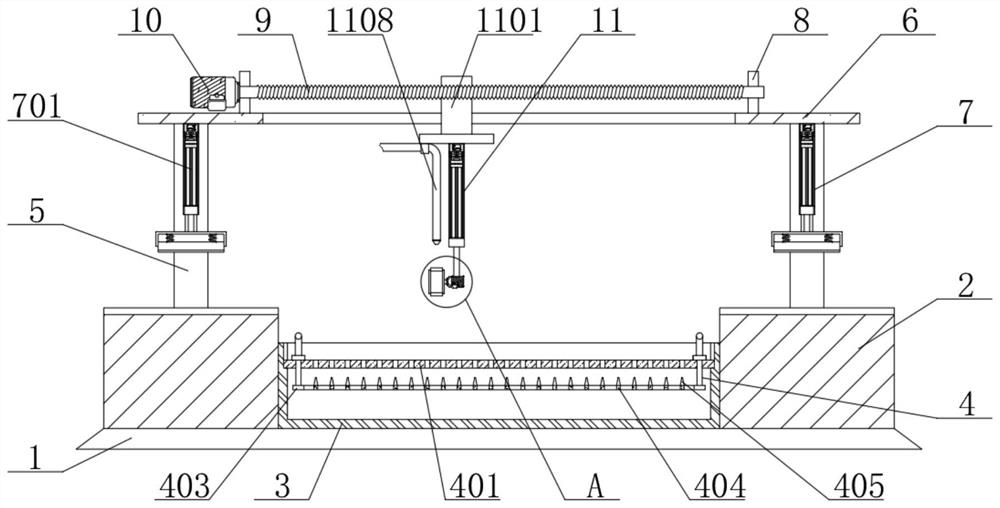

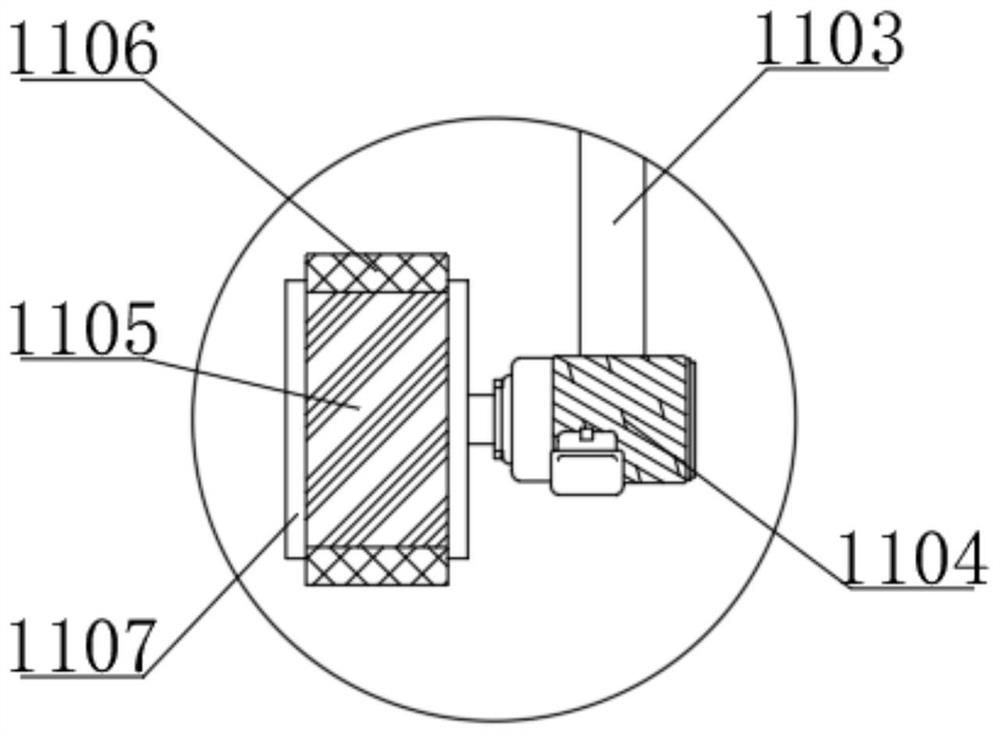

[0025]A polishing and cleaning device for automobile welding, including a base 1, a collection box 3, a support frame 5, and a top plate 6. The top of the base 1 is fixedly connected with a placing table 2 on both sides, and the center of the top of the placing table 2 has an arc-shaped concave A collection box 3 is fixedly connected to the inside of the collection box 3 in the middle position of the platform 2 on both sides. The filter device 4 includes a filter plate 401, a connecting rod 402, a bottom plate 403 and a fixed cone 405, The plate 401 is slidably connected to the inner end surface of the collection box 3. The front and rear ends of the placing table 2 are fixedly connected with a support frame 5, the top of the support frame 5 is fixedly connected with a top plate 6, and the bottom ends of the top plate 6 are fixedly connected with compression Device 7, the pressing device 7 includes

Example Embodiment

[0028]Example 2:

[0029]SeeFigure 1-6, The present invention provides a technical solution:

[0030]A polishing and cleaning device for automobile welding, including a base 1, a collection box 3, a support frame 5, and a top plate 6. The top of the base 1 is fixedly connected with a placing table 2 on both sides, and the center of the top of the placing table 2 has an arc-shaped concave A collection box 3 is fixedly connected to the inside of the collection box 3 in the middle position of the platform 2 on both sides. The filter device 4 includes a filter plate 401, a connecting rod 402, a bottom plate 403 and a fixed cone 405, The plate 401 is slidably connected to the inner end surface of the collection box 3, the front and rear ends of the placing table 2 are fixedly connected with a support frame 5, the top of the support frame 5 is fixedly connected with a top plate 6, and the bottom ends of the top plate 6 are fixedly connected with compression Device 7, the pressing device 7 includes

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap