Cis-5-norbornene-exo-2,3-dicarboxylic anhydride crystal form and preparation method thereof

A technology of nadic acid anhydride and appearance, which is applied in the field of appearance nadic acid anhydride crystal form and its preparation, can solve the problems of long-term storage and transportation of unfavorable appearance nadic acid anhydride, poor hygroscopic stability of outer shape nadic acid anhydride, etc., and achieve Ease of long-term storage and transportation, simple and easy operation, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the exo-nadic anhydride crystal form of this embodiment, the exo-nadic anhydride crystal form is the exo-nadic anhydride crystal form of Example 1 of the exo-nadic anhydride crystal form, comprising the following steps:

[0035] Under the condition of 50°C, stir and dissolve 5g of exo-nadic anhydride in 15g of dioxane. After the dissolution is complete, cool the solution to 0°C and keep it for 2h. The precipitated crystals are suction-filtered, washed with alcohol and dried to obtain exo Nadic acid anhydride crystal form.

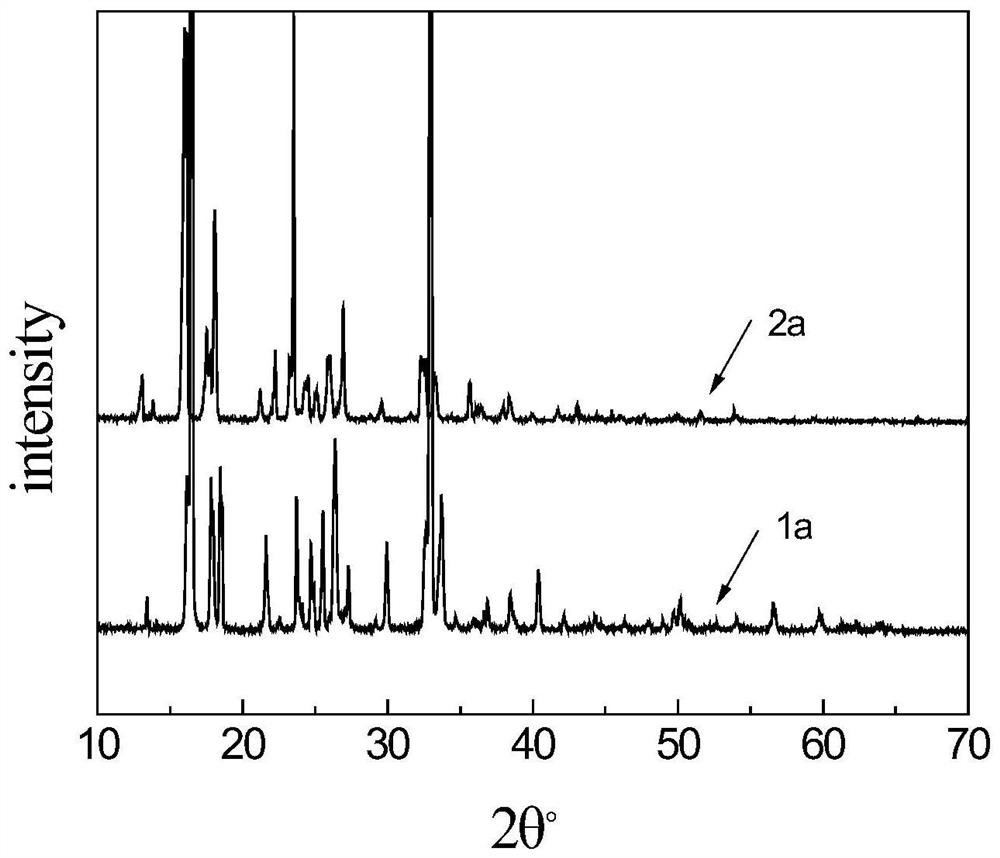

[0036] The XRD test results of exo-nadic anhydride and exo-nadic anhydride crystal form are shown in the appendix figure 1 The purity of the product obtained by gas chromatography (GC-7900) analysis is 98.94%, and the primary precipitation yield is about 62.32%.

Embodiment 2

[0038] The preparation method of the exo-nadic acid anhydride crystal form of the present embodiment comprises the following steps:

[0039] At 20°C, stir and dissolve 5g of exo-form Nadic anhydride in 18g of N-methylpyrrolidone (NMP). After the dissolution is complete, cool the solution down to 0°C and keep it for 2h. Suction filter the precipitated crystals and wash them with alcohol. , After drying, the Nadic acid anhydride crystal form is obtained.

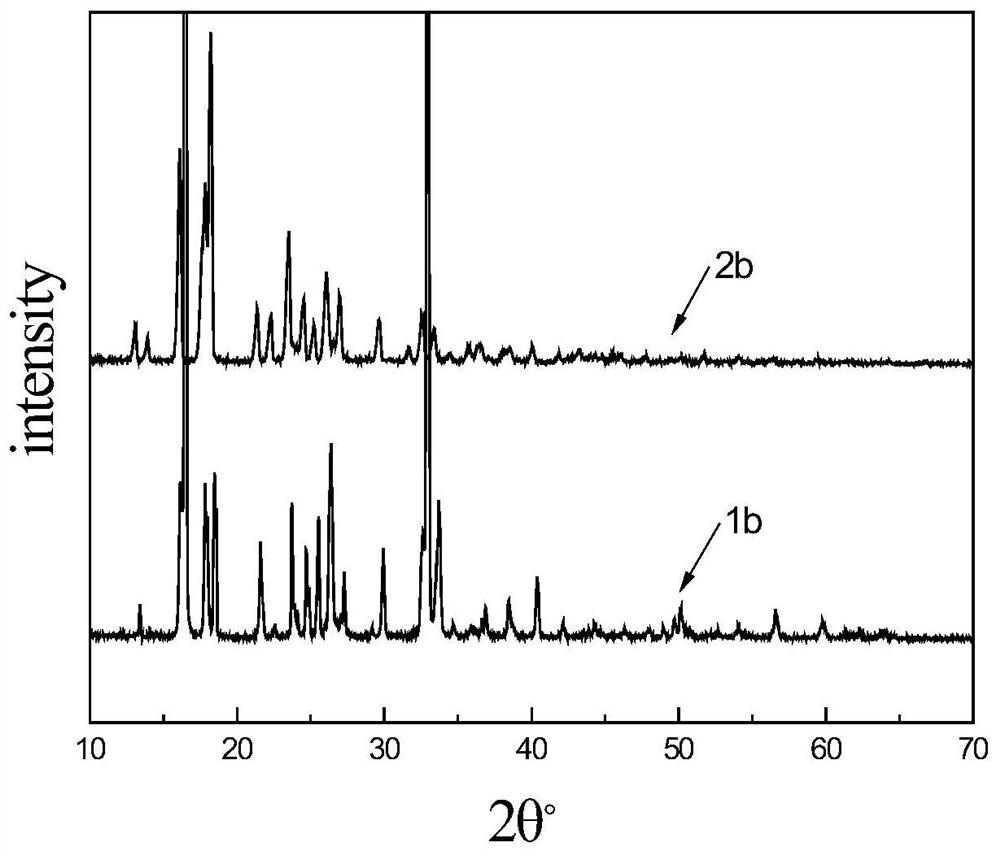

[0040] The XRD test results of exo-nadic anhydride and exo-nadic anhydride crystal form are shown in the appendix figure 2 The purity of the product obtained by gas chromatography (GC-7900) analysis is 99.12%, and the primary precipitation yield is about 64.46%.

Embodiment 3

[0042] The preparation method of the exo-nadic acid anhydride crystal form of the present embodiment comprises the following steps:

[0043] Under the condition of 50°C, stir and dissolve 5g of exo-nadic anhydride in 12g of dimethylformamide (DMF). The crystals were suction filtered, washed with alcohol and dried to obtain the Nadic acid anhydride crystal form.

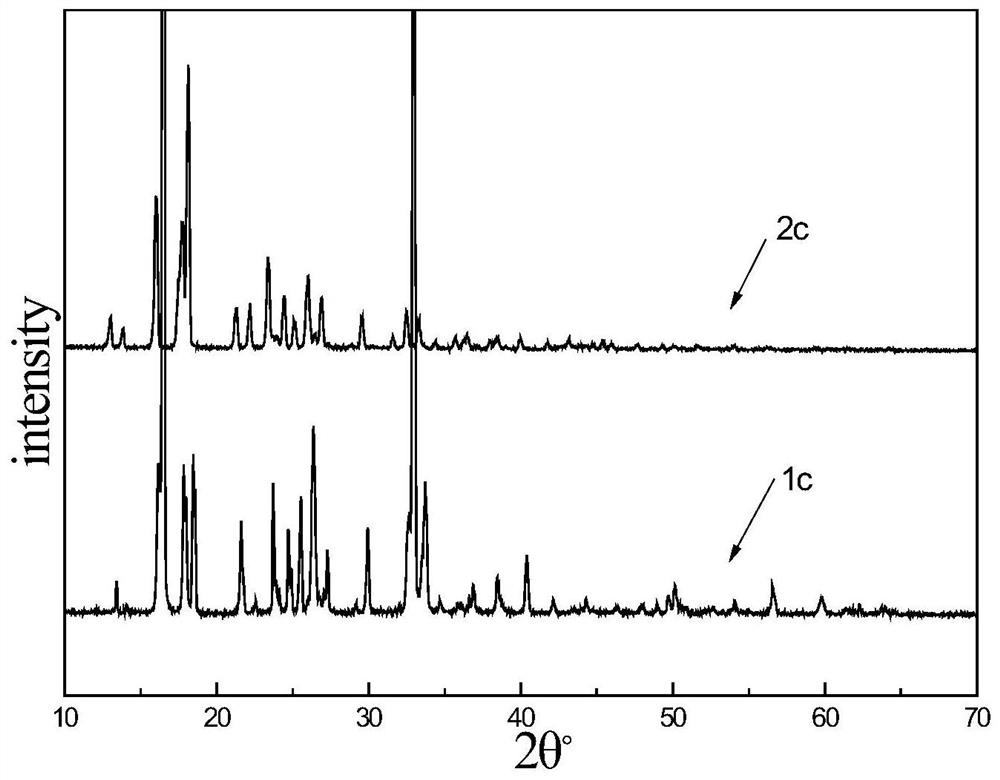

[0044] The XRD test results of exo-nadic anhydride and exo-nadic anhydride crystal form are shown in the appendix image 3 The purity of the product obtained by gas chromatography (GC-7900) analysis is 99.01%, and the primary precipitation yield is about 58.12%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap