Capping machine

A technology of capping machine and rack, which is applied to conveyors, conveyor objects, flanged bottle caps, etc., can solve the problems of time-consuming and laborious operation, manual installation, low work efficiency, etc., to avoid manual operation and facilitate pressing. The effect of tightly sealing the cover and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

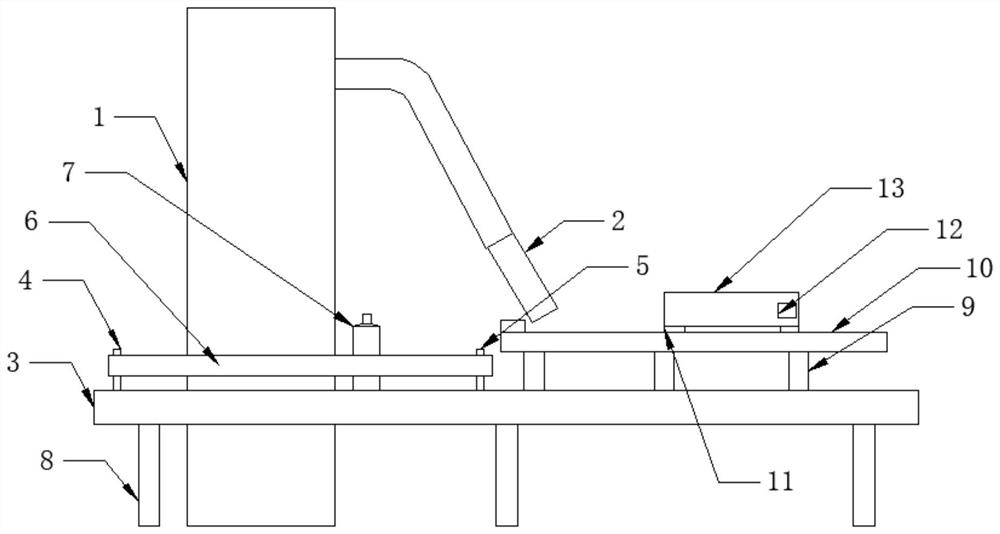

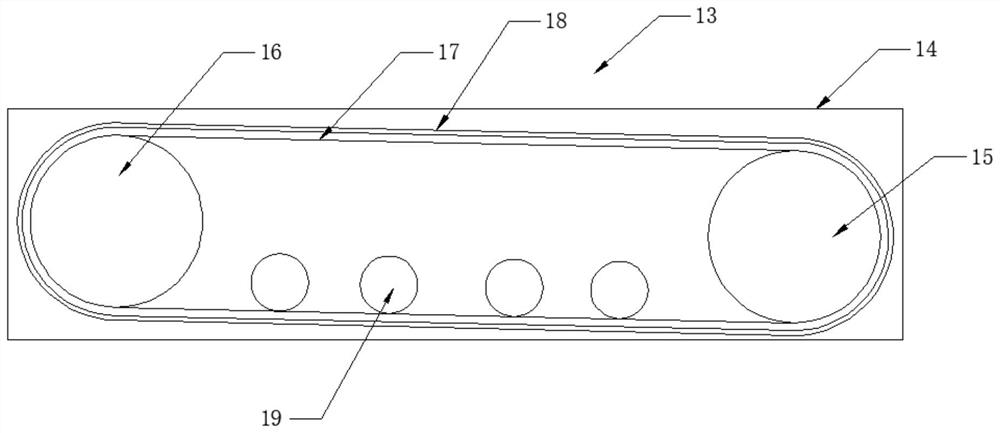

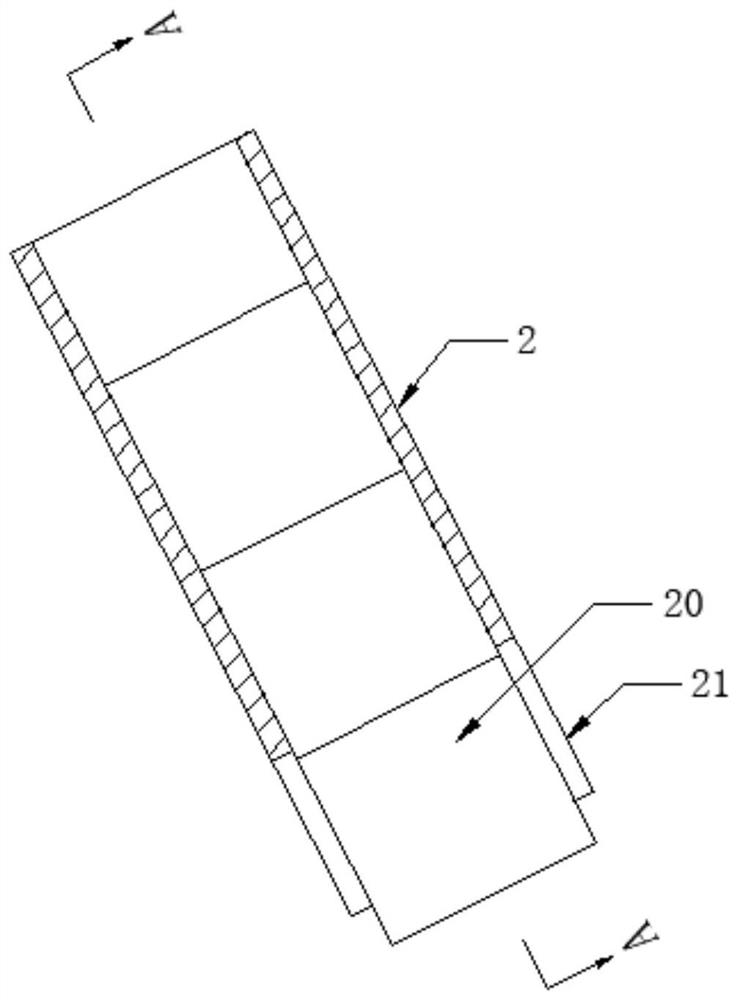

[0025] see Figure 1-4 , the present invention provides a technical solution: a capping machine, including a frame 3, a conveyor belt is installed in the middle of the frame 3, the conveyor belt is driven by a first motor, and support feet are fixedly connected to the bottom of the frame 3 8. Clamping devices are provided on the front and rear sides above the frame 3, the clamping devices include a pressure belt 6, a driving roller 4 and a driven roller 5, and the driving roller 4 is installed on the left side above the frame 3 , the driving roller 4 is rotationally connected with the frame 3, and the driving roller 4 is driven by a second motor, the driven roller 5 is installed on the right side above the frame 3, and the driven roller 5 and the frame 3 Rotationally connected, a pressure belt 6 is installed between the driving roller 4 and the driven roller 5, and the second motor drives the driving roller 4 to rotate so that the pressure belt 6 moves, and the pressure belts 6 o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap