Method for anaerobic fermentation of organic household garbage of villages and small towns

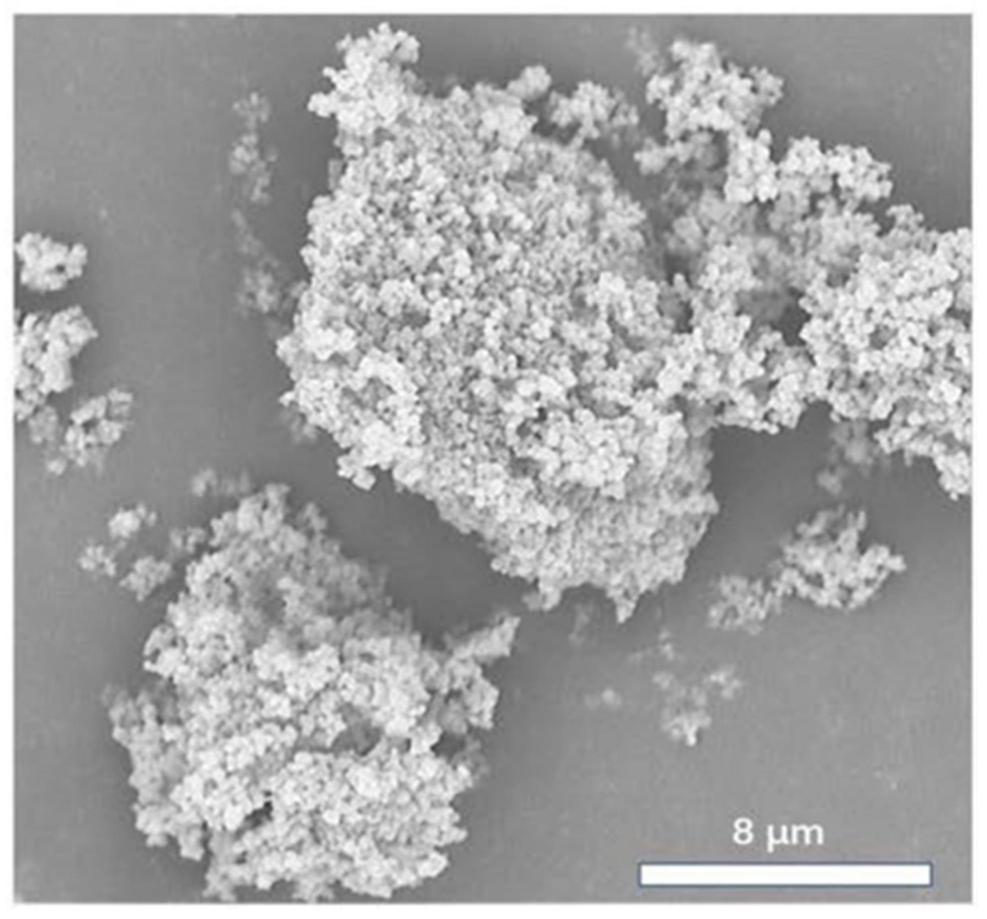

A technology of organic domestic waste and anaerobic fermentation, applied in fermentation, chemical instruments and methods, biological sludge treatment, etc., can solve the problems of ammonia inhibition and achieve the effects of eliminating ammonia inhibition, large application potential, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The inoculum was taken from the sludge of Yongkang Agriculture and Animal Husbandry Technology Co., Ltd. in Jintan District, Changzhou City, Jiangsu Province. It was in the form of black flocculent. After taking it back and sealing it, put it in a water bath at 37°C for acclimatization, and save it for later use. Use a mixer device to mix well. The organic domestic waste used in the experiment was prepared by referring to the composition of organic domestic waste in Datun Street, Pei County. Its main components are fresh vegetable leaves and melon peels, which were crushed with a grinder until the particle size was less than 4mm, and stored in the refrigerator.

[0022] The experimental device is composed of a solid anaerobic fermentation tank, a drainage bottle and a gas collecting bottle. The volume of the fermenter is 30L, the effective volume of the fermenter is set to 24L, the TS is 20% feed, the pH value is adjusted to 7.5, and then the fermentation is started after

Embodiment 2

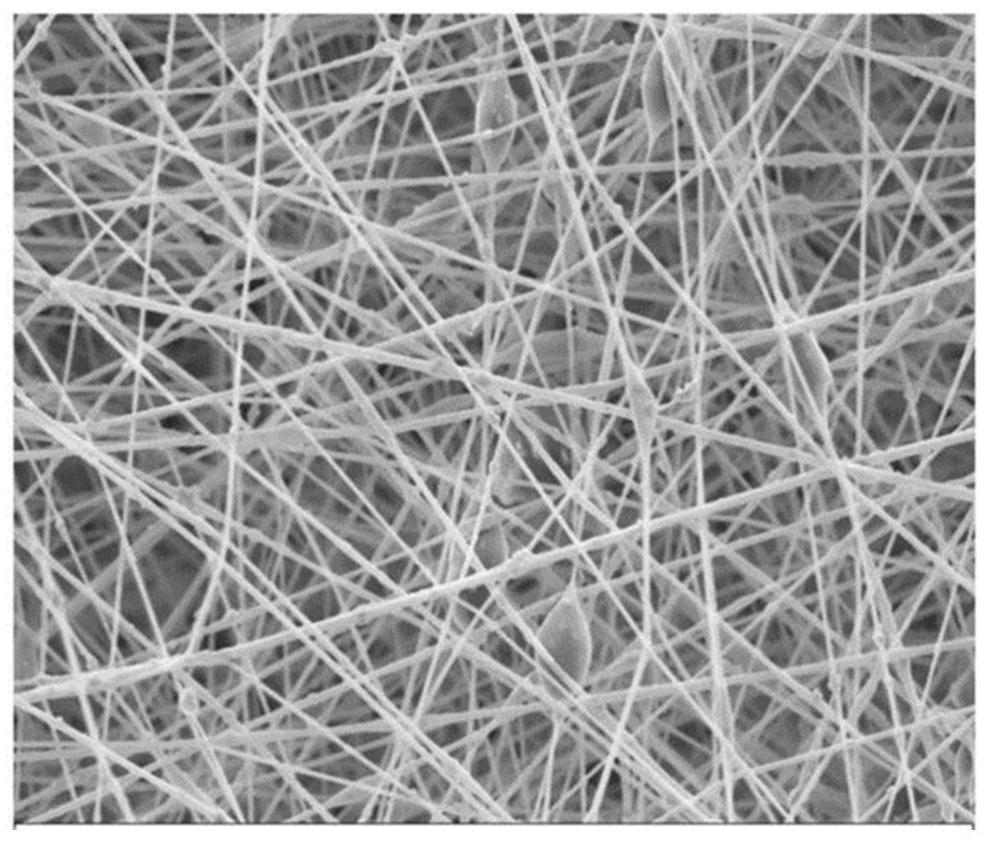

[0029] FeZn Prussian blue / polyacrylonitrile composite nanofiber membrane, the preparation method is as follows: Weigh 0.75g of polyacrylonitrile (PAN) and dissolve it in 10mL of N,N dimethylformamide (DMF), stir magnetically at 60°C for 3h, make After it was completely dissolved, 1.5 g of Prussian blue compound was added and stirred until uniformly dispersed to obtain an electrospinning solution.

[0030] Pour the electrospinning liquid into a 10mL syringe, set the voltage of the electrospinning machine to 13KV, the distance is 15cm, and the injection rate is 0.012mL / min, and the FeZn Prussian blue / polyacrylonitrile composite nanofiber membrane is obtained by spinning.

[0031] Other parameters of the fermentation method are the same as in Example 1.

Embodiment 3

[0033] FeZn Prussian blue / polyacrylonitrile composite nanofiber membrane, the preparation method is as follows: Weigh 1.0g polyacrylonitrile (PAN) dissolved in 10mL of N,N dimethylformamide (DMF), magnetically stir at 60°C for 3h, make After it was completely dissolved, 1.5 g of Prussian blue compound was added and stirred until uniformly dispersed to obtain an electrospinning solution.

[0034] Pour the electrospinning solution into a 10mL syringe, set the voltage of the electrospinning machine to 14KV, the distance is 12cm, and the injection rate is 0.008mL / min, and the FeZn Prussian blue / polyacrylonitrile composite nanofiber membrane is obtained by spinning.

[0035] Other parameters of the fermentation method are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap