Blank oil sample preparation device and method for transformer insulating oil

A transformer insulating oil and preparation device technology, which is applied in the preparation of test samples, measuring devices, instruments, etc., can solve problems such as instability, influence on test results, and poor operability, so as to improve the reliability of preparation and avoid air pollution , The effect of stable flooding degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

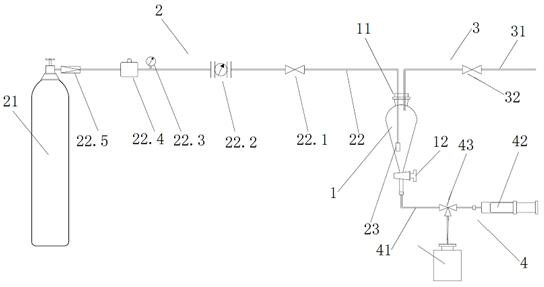

[0025] Combine below figure 1 Embodiments of the present invention are described in detail.

[0026] The blank oil sample preparation device for transformer insulating oil is characterized in that it includes a drive clean room 1 containing insulating oil, a gas input assembly 2 for inputting inert gas into the drive clean room 1, and passing into the drive clean room 1 for exhaust The gas discharge assembly 3 and the oil sample output assembly 4 connected to the flushing chamber 1 for sampling and oil treatment, the gas input assembly 2 input gas to the flushing chamber 1 to perform bubbling and purging of the insulating oil Finally, the oil sample is pressed into the oil sample output assembly 4.

[0027] In the above-mentioned blank oil sample preparation device for transformer insulating oil, the insulating oil is contained in the clean driving room 1, and the gas input assembly 2 inputs inert gas into the clean driving room 1, and the insulating oil is bubbled and purged, a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap