High-temperature bending fatigue in-situ test device and method

A technology of bending fatigue and in-situ testing, applied in the direction of measuring devices, using stable bending force to test the strength of materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

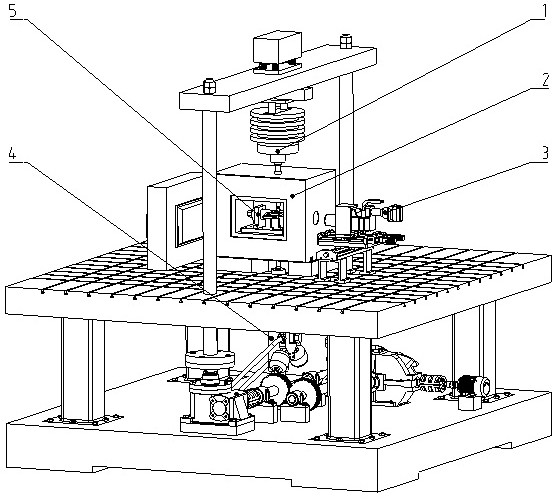

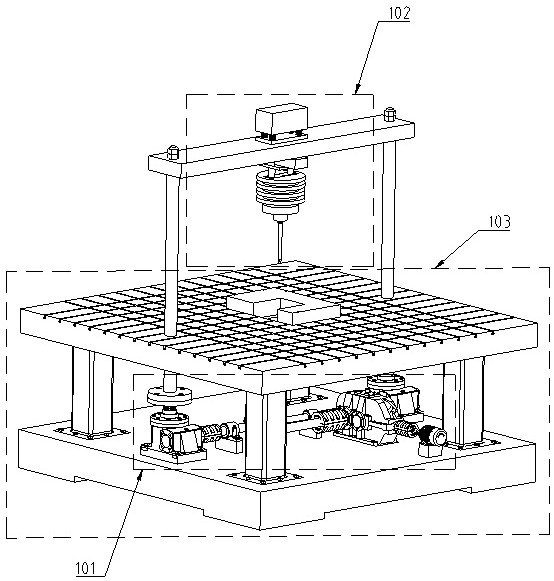

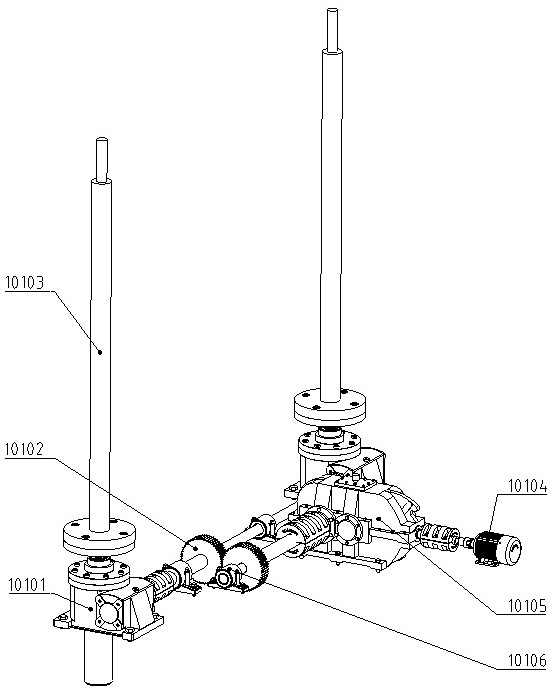

[0046] see Figure 1 to Figure 20 As shown, the high-temperature bending fatigue in-situ testing device and method of the present invention, the device is composed of an electromagnetic resonance loading module, a hydraulic loading module, a high-temperature loading module, an in-situ monitoring module, and a sample clamping device. Among them, the electromagnetic resonance loading module can realize the high frequency bending fatigue loading of the tested material sample; the hydraulic loading module can realize the low frequency bending fatigue loading of the tested material sample; the high temperature loading module can realize the high temperature and variable temperature of the tested material sample Environmental loading; the in-situ monitoring module can monitor the characteristics and mechanism of crack init

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap