Magnesium based anode electrochemical performance constant current quick test method

A test method and electrochemical technology, applied in the direction of material electrochemical variables, etc., can solve problems such as not being suitable for large-scale production on-line detection, affecting the production efficiency of anode products, and lagging the production cycle, so as to shorten the test cycle, promote production efficiency, method fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] 2. Preparation of anode test electrolyte and anode cleaning solution

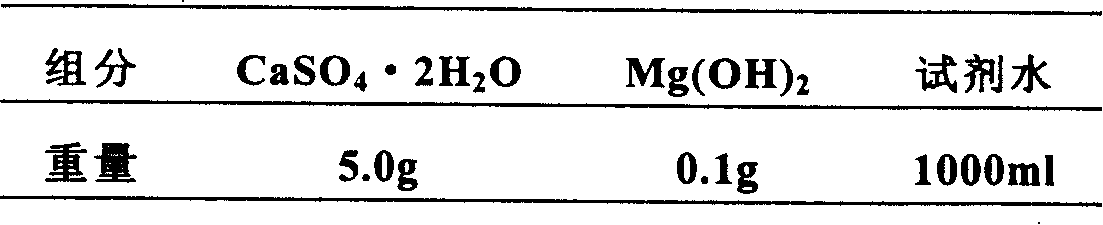

[0027] 2.1 See Table 1 for the proportion and composition of the electrolyte in the anode test:

[0028] Table 1 Composition of test dielectric fluid

[0029]

[0030] 2.2 Anode cleaning solution: 250g reagent grade CrO 3 Prepare by adding 1000ml of Type IV or higher reagent grade water.

[0031] 3. Test operation

[0032] 3.1 Add the anode test electrolyte to the cathode test crucible, and the solution is about 15mm away from the mouth;

[0033] 3.2 Insert the sample into the 14# rubber stopper, and then put it into the cathode test crucible. The area where the sample is immersed in the electrolyte is 41.2cm 2 ;

[0034] 3.3 press figure 1 Connect the test line as shown;

[0035] 3.4 Turn on the power and adjust the current to a suitable value, and keep the current density at 0.05-0.2mA / cm 2 Between (0.11mA / cm 2 preferred);

[0036] 3.5 Use a saturated calomel electrode and a potentiom

Embodiment 1

[0066] 1. Select 11#, 12#, 13#, 14#, 15# (set as the first group AZ31) samples according to the sample preparation requirements;

[0067] 2. Connect to the test line and measure according to the above test steps;

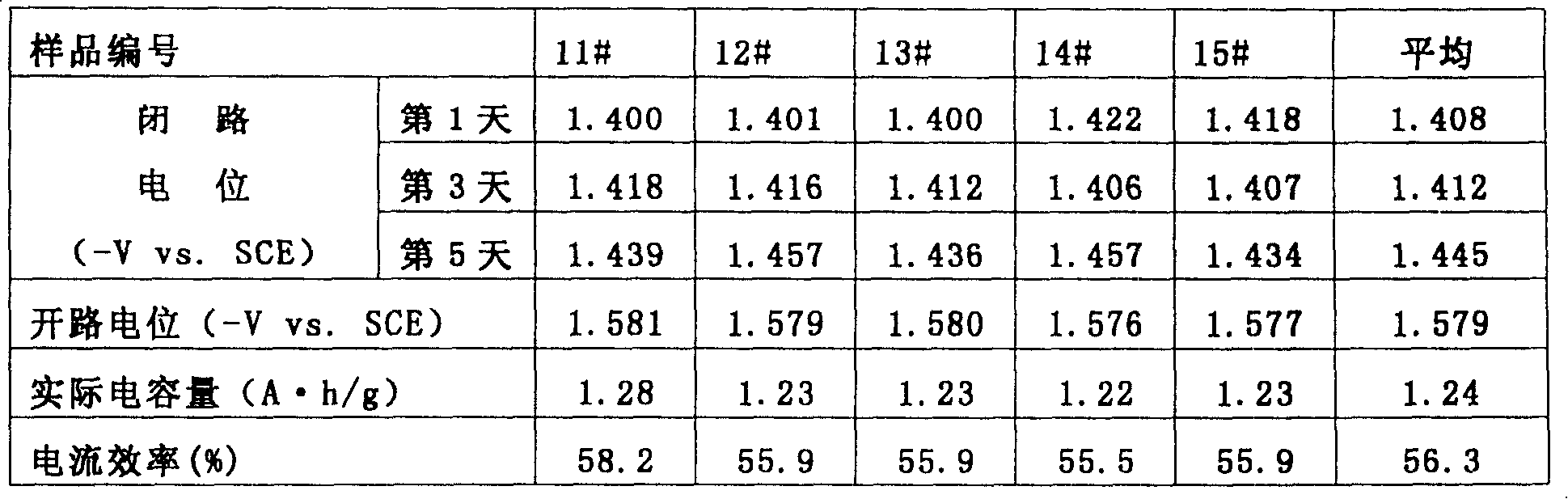

[0068] 3. Obtain the electrochemical performance test report (see Table 2).

[0069] Table 2 The first group of AZ31 magnesium anode electrochemical performance test report

[0070]

Embodiment 2

[0072] 1. Select 21#, 22#, 23#, 24#, 25# (set as the second group AZ31) samples according to the sample preparation requirements;

[0073] 2. Connect to the test line and measure according to the above test steps;

[0074] 3. Obtain the electrochemical performance test report (see Table 3).

[0075] Table 3 The second group AZ31 magnesium anode electrochemical performance test report

[0076]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap