Sucralose continuous acylation reaction device and sucralose continuous acylation reaction method

An acylation reaction, sucralose technology, applied in chemical instruments and methods, esterified saccharides, sugar derivatives, etc., can solve the problems of material drop rate, difficult temperature control, increased by-products, material carbonization, etc. Shorten the production cycle, improve the conversion rate, the effect of sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

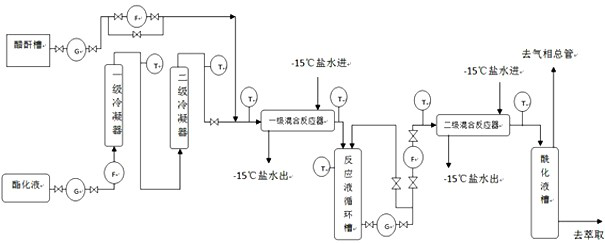

[0020] (1) Put the esterification solution (10°C) at 3.5m 3 The amount of / L is condensed through the primary condenser and the secondary condenser in turn. The temperature of the primary condenser is controlled at -1°C and the temperature of the secondary condenser is -3°C. The condensed esterification liquid is condensed at 2.5m 3 / L into the primary mixing reactor;

[0021] (2) Add acetic anhydride to 0.3m 3 / L into the first-stage mixing reactor, the temperature of the first-stage mixing reactor is controlled at -3°C, the pressure is 0.17Mpa, and the material from the first-stage mixing reactor is 3.5m 3 / L enters the reaction liquid circulation tank (circulation 7.5min), then passes through the pump at 3.5m 3 / L into the secondary mixing reactor, the temperature of the secondary mixing reactor is controlled at -1.5°C and the pressure is 0.17Mpa;

[0022] (3) The material from the secondary mixing reactor is 3.5m 3 / L into the esterification liquid tank, and t

Embodiment 2

[0024] (1) Put the esterification solution (8°C) at 3.1m 3 The amount of / L is condensed through the primary condenser and the secondary condenser in turn. The temperature of the primary condenser is controlled at -2°C and the temperature of the secondary condenser is -3.8°C. The condensed esterification liquid is 3.1m 3 / L into the primary mixing reactor;

[0025] (2) Add acetic anhydride to 0.25m 3 / L into the first-stage mixing reactor, the temperature of the first-stage mixing reactor is controlled at -3.8°C, the pressure is 0.15Mpa, and the material from the first-stage mixing reactor is 3.1m 3 / L enters the reaction liquid circulation tank (circulation 5min), and then passes through the pump at 3.1m 3 / L into the secondary mixing reactor, the temperature of the secondary mixing reactor is controlled at -2°C and the pressure is 0.15Mpa;

[0026] (3) The material from the secondary mixing reactor is 3.1m 3 / L into the esterification liquid tank, and then sent

Embodiment 3

[0028] (1) Put the esterification solution (12°C) at 4m 3 The amount of / L is condensed through the primary condenser and the secondary condenser in turn. The temperature of the primary condenser is controlled at 0°C and the temperature of the secondary condenser is -2°C. The condensed esterification liquid is condensed at 4m 3 / L into the primary mixing reactor;

[0029] (2) Add acetic anhydride to 0.4 m 3 / L into the first-stage mixing reactor, the temperature of the first-stage mixing reactor is controlled at -2°C, the pressure is 0.2 Mpa, and the material from the first-stage mixing reactor is 4m 3 / L into the reaction liquid circulation tank (circulation 10min), then through the pump at 4m 3 / L into the secondary mixing reactor, the temperature of the secondary mixing reactor is controlled at -1°C and the pressure is 0.2 Mpa;

[0030] (3) The material from the secondary mixing reactor is 4 m 3 / L into the esterification liquid tank, and then sent to extractio

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap