Environment-friendly marine antifouling coating and preparation method thereof

An environmentally friendly, marine antifouling technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc. The effect of preventing biofilm formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] Example 1

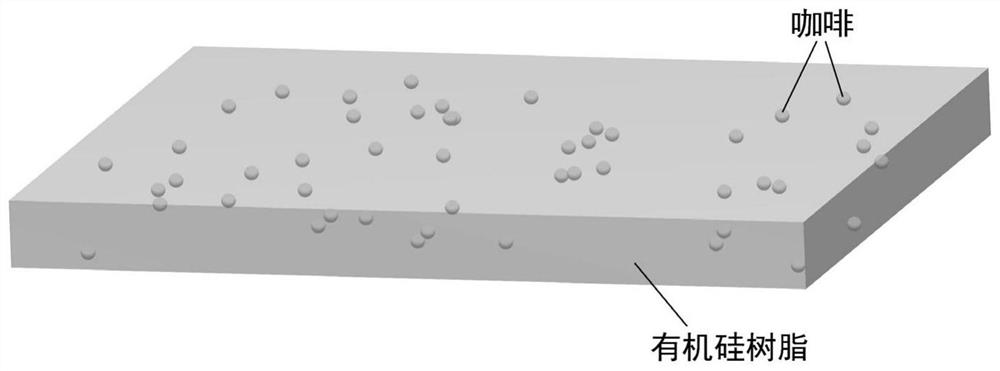

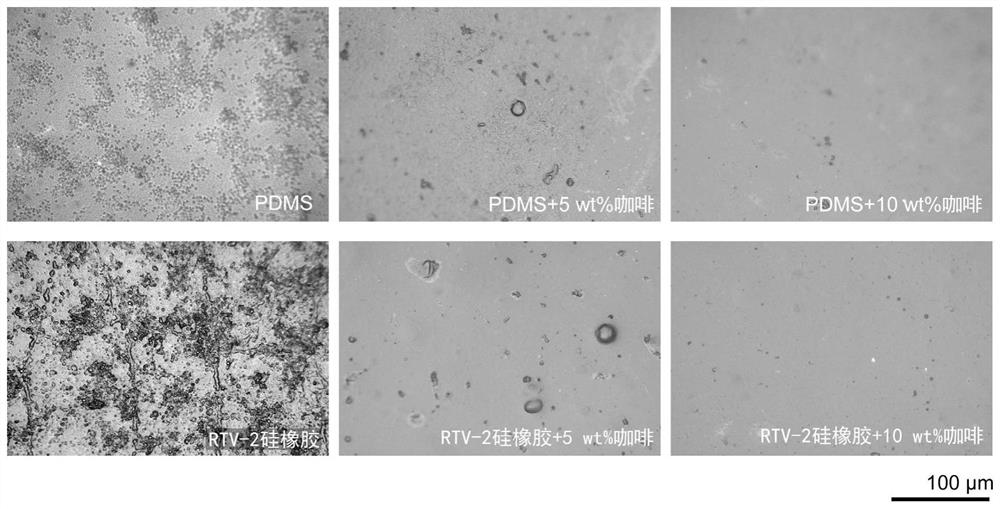

[0019] like figure 1 As shown, in this embodiment, the environmentally friendly marine antifouling coating is made of silicone resin as the matrix, and coffee particles of more than 150 meshes are dispersed in the matrix. The silicone resin is a two-component silicone resin. In the example, it is PDMS, and the mass of coffee particles is 4% to 5% of the total mass of the coating.

[0020] (1) Preparation of coffee dispersion

[0021] The pure coffee was ground in a ceramic mortar for 20 minutes and then screened with a 150-mesh metal sample sieve to remove large coffee particles. After that, the coffee was added to anhydrous ethanol to dissolve (mass ratio 1:4), stirred with a mechanical stirrer for 10 minutes, and then placed in an ultrasonic cleaner to shake for 30 minutes to obtain a coffee dispersion.

[0022] (2) Preparation of silicone resin dispersion

[0023] Pour the silicone resin component A into tetrahydrofuran, then keep stirring at a water bat

Example Embodiment

[0026] Example 2

[0027] The difference between this example and Example 1 is that the added silicone resin is RTV-2 silicone rubber, and the mass ratio of its AB components is A:B=100:1.5.

Example

[0028] Example 3 and Example 4

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap