Socket sealing structure for ensuring reliable connection of pipelines

A kind of sealing structure and reliable technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problem of rubber ring detachment or twisting, rubber ring installation problems, and laborious and laborious inspection of feeler gauges, etc. problems, to avoid dislocation and distortion, to ensure tightness, and to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

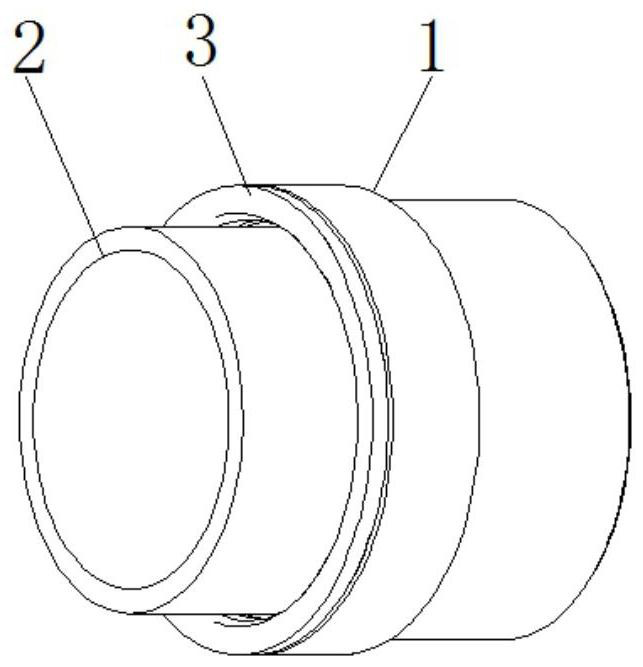

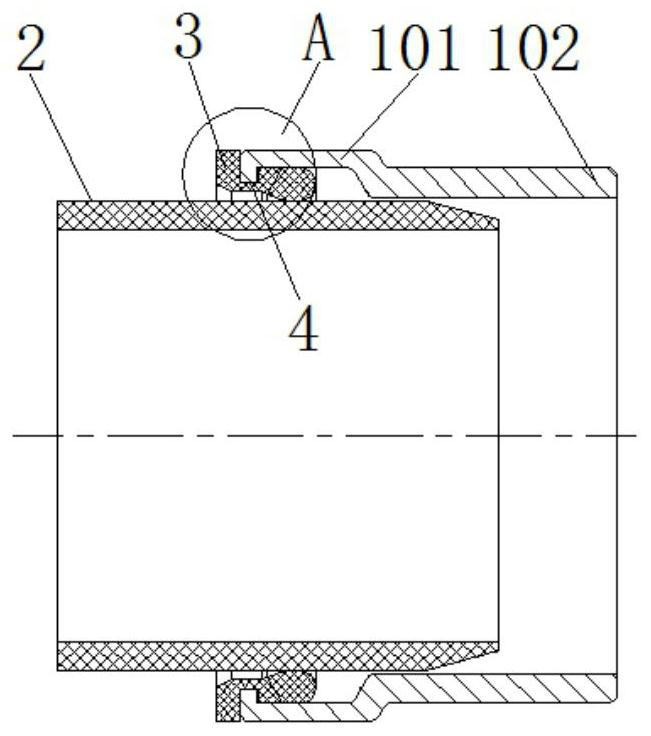

[0031] like figure 1 As shown, this embodiment discloses a socket sealing structure to ensure the reliable connection of pipelines, including a pipe socket 1, a pipe socket 2 and a sealing rubber ring 3 placed at the joint of the two. The sealing rubber ring 3 is located on the pipe socket In the interlayer between port 1 and tube socket 2. The insertion end surface of the sealing rubber ring 3 is exposed outside the end of the pipe socket 1, and the socket end face of the sealing rubber ring 3 is always outside the pipe socket 1, so that it can be visually judged whether the socket is equipped with an apron and whether the apron is In place, it is not necessary to use a feeler gauge to check the sockets one by one.

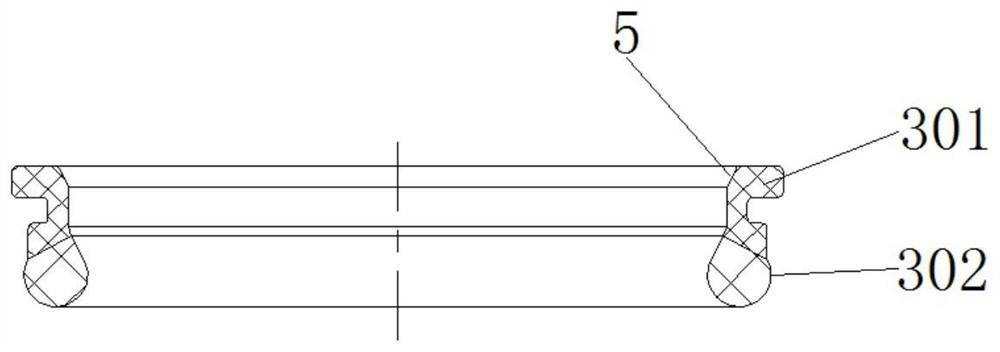

[0032] like figure 2 and 3 As shown, in this embodiment, the sealing rubber ring 3 includes a hard rubber positioning part 301 and a soft rubber sealing part 302 of an integral structure; the cut surface of the hard rubber positioning part 301 is T-shaped, and

Embodiment 2

[0039] like Figure 5 As shown, in this embodiment, there are two annular positioning structures 4 , and the annular positioning structure 4 includes an annular protruding ring 401 and an annular groove 402 that cooperate with each other. The annular protruding ring 401 is arranged on the inner wall of the pipe socket 1 , and the annular groove 402 is arranged on the outer wall of the hard glue positioning part 301 . The rest of the structure is the same as that of Embodiment 1, and will not be described again.

Embodiment 3

[0041] like Image 6 As shown, in this embodiment, there is one annular positioning structure 4 , and the annular protruding ring 401 is located inside the end of the pipe socket 1 . The rest of the structure is the same as that of Embodiment 1, and will not be described again.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap