Method for supporting ultra-thin roof roadway under goaf

A technology for roadway support and goaf, which is applied in the field of extremely thin roof roadway support under the goaf, which can solve the problems of easy falling off of roof anchor components, easy damage of supporting structure, and low supporting efficiency, so as to reduce falling off Probability of failure, enhanced strength, and the effect of saving support costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

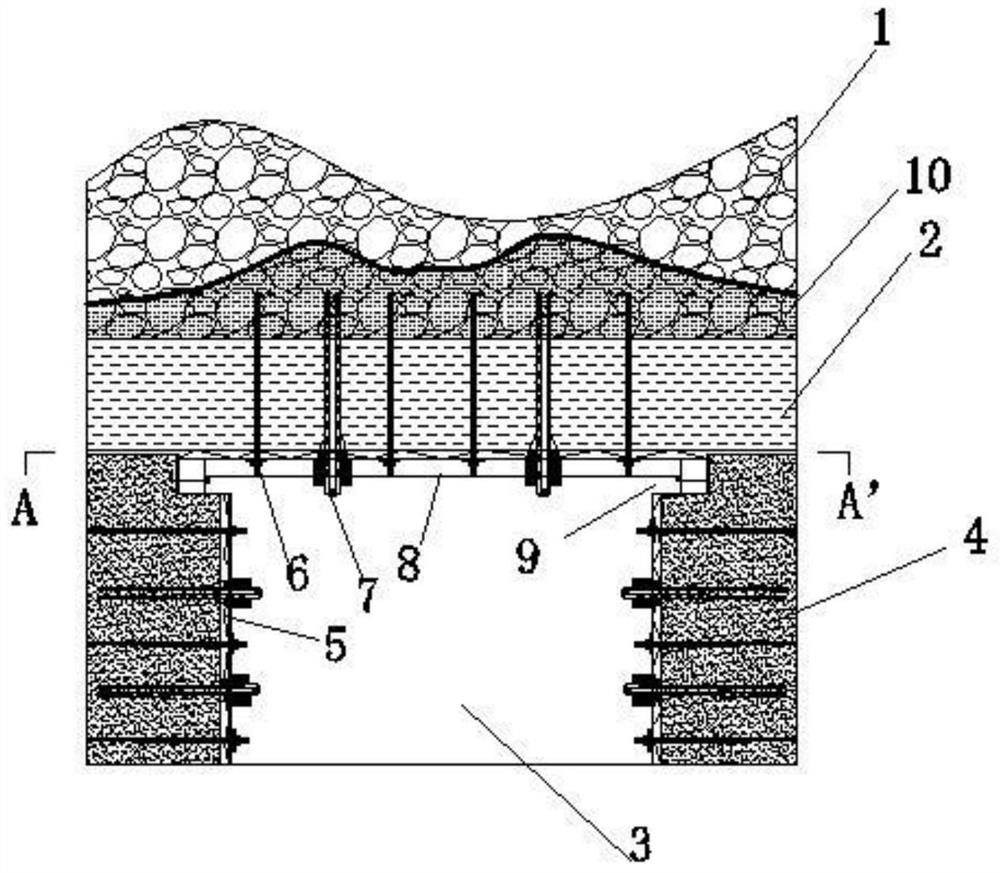

[0033] A method for supporting roadways with extremely thin roofs in goafs, comprising the following steps.

[0034] Step 1. Through theoretical calculation, the periodical compressive load q on the roof of roadway 3 is obtained, and the calculation formula of q is: q=kMγ / (k p -1) , where: k is the dynamic load coefficient of the roof period, generally 1.2~2.0 (can be determined according to the monitoring data of the adjacent working face mine pressure); M is the thickness of the coal seam; k p Roof rock breaking expansion coefficient; γ average bulk density of roof rock layer.

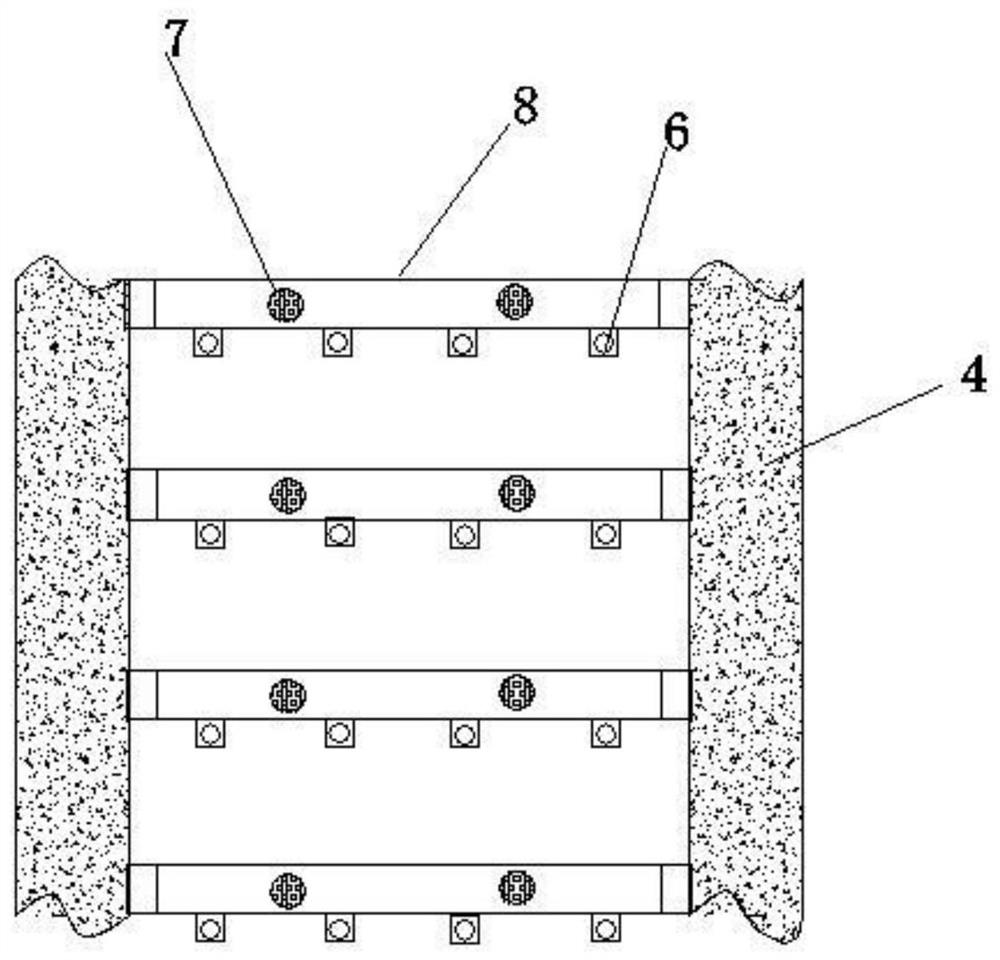

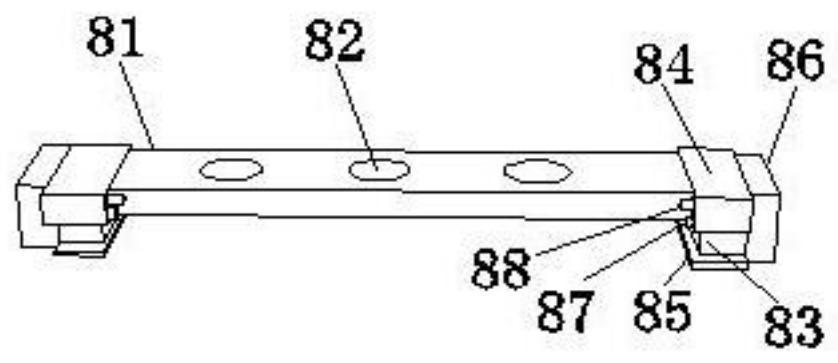

[0035] Step 2, according to the cross-sectional size of the roadway 3 and the roof period calculated in the step 1, the compression load q is used to make the pressure beam 8, specifically: see image 3 , let pressure beam 8 be made up of channel steel 81, piston 83, telescopic cylinder 84, support plate 85, buffer pad 86; Channel steel 81 is provided with round hole 82; Connect the piston 83, the p

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap