Formula and production process of crispy meat

A recipe and technology of crispy meat, which is applied in food mechanical processing, food science, etc., can solve problems such as poor taste, inability to meet food needs, low softness and chewiness of crispy meat, and improve the taste and crispness of meat , Improve chewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

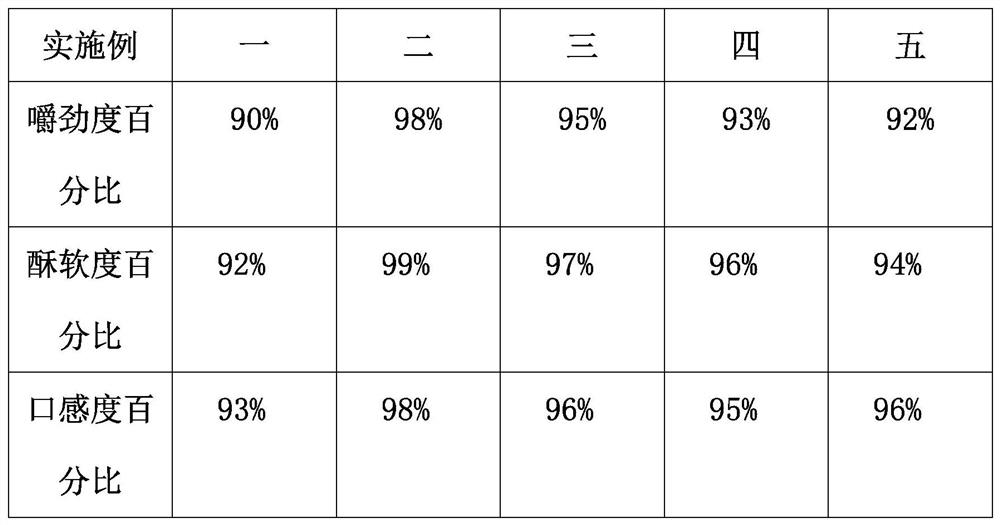

Examples

Embodiment 1

[0025] This embodiment proposes a recipe for crispy meat, including the following raw materials in parts by weight: 30.0 kg of meat, 0.5 kg of compound mold preparation, 0.64 kg of soybean protein, 0.35 kg of salt, 0.10 kg of chicken essence, meat 0.02kg for Zhongbao, 0.008kg for shallot powder, 0.20kg for garlic powder, 0.040kg for ginger powder, 0.20kg for light soy sauce, 0.01kg for dark soy sauce, 0.01kg for pepper powder, 0.10kg for white sugar, India 0.020kg for pepper, 0.38kg for KH-05 water retaining agent, 2.8kg for water, 0.4kg for raw flour, 0.6kg for corn flour, 4.10kg for red tea powder, 0.3kg for flour, 0.070kg for fried chicken powder, Twist crisps are 0.024kg, chicken powder is 0.25kg, crispy treasure is 0.070kg, essence is 0.04kg, and seasoning powder is 0.2kg. The seasoning powder can be spicy powder, garlic powder, cumin powder, curry powder, scallion powder It can be any one of powder or black pepper, and its meat can be any one of pork, beef, mutton, chicken,

Embodiment 2

[0038] This example proposes a formula and production process for crispy meat, including the following raw materials in parts by weight: 30.3 kg for meat, 0.53 kg for compound mold preparation, 0.66 kg for soybean protein, 0.37 kg for salt, and 0.12 kg for chicken essence. kg, 0.03kg for Rouzhongbao, 0.009kg for chive powder, 0.21kg for garlic powder, 0.042kg for ginger powder, 0.21kg for soy sauce, 0.02kg for dark soy sauce, 0.02kg for pepper powder, and 0.12kg for white sugar kg, 0.024kg for Indian pepper, 0.39kg for KH-05 water retaining agent, 2.9kg for water, 0.45kg for raw flour, 0.7kg for corn flour, 4.13kg for red tea powder, 0.35kg for flour, and 0.35kg for fried chicken powder 0.071kg, 0.025kg of Mahua crisp, 0.27kg of chicken powder, 0.073kg of crispy treasure, 0.045kg of essence, 0.3kg of seasoning powder, the seasoning powder can be spicy powder, garlic powder, cumin powder, curry powder Any one of , scallion powder or black pepper powder, and the meat can be any one

Embodiment 3

[0051] This example proposes a formula and production process for crispy meat, including the following raw materials in parts by weight: 30.5 kg for meat, 0.55 kg for compound mold preparation, 0.69 kg for soybean protein, 0.4 kg for salt, and 0.13 kg for chicken essence. kg, Rouzhongbao 0.04kg, shallot powder 0.01kg, garlic powder 0.22kg, ginger powder 0.044kg, light soy sauce 0.22kg, dark soy sauce 0.03kg, pepper powder 0.03kg, white sugar 0.13 kg, Indian pepper is 0.026kg, KH-05 water retaining agent is 0.4kg, water is 3.0kg, raw flour is 0.5kg, corn flour is 0.8kg, red tea powder is 4.15kg, flour is 0.4kg, fried chicken powder is 0.072kg, Mahua crisp 0.026kg, chicken powder 0.3kg, crispy treasure 0.075kg, essence 0.05kg, seasoning powder 0.4kg, the seasoning powder can be spicy powder, garlic powder, cumin powder, curry powder Any one of , scallion powder or black pepper powder, and the meat can be any one of pork, beef, mutton, chicken, duck, fish, rabbit, goose, shrimp or o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap