Calculation method for bending resistance test of finished COF Film

A calculation method and bending resistance technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve problems such as difficult to accurately reflect the bending resistance of lines, and the scrapping of COFFilm finished products, so as to reduce the number of tests and test time , The effect of avoiding scrapped finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for calculating the bending resistance of a finished COF Film prepared from a company A base material (raw material prepared by A company), comprising the following steps:

[0035] S1: Take company A’s base material and go through the existing COF Film process to prepare a standard MIT serpentine test circuit, and take a standard circuit with a line width of 12um and a pitch (line width + line spacing) of 22um for a bending resistance test.

[0036] S2: The bending resistance test method refers to the test method in the international standard JIS P8115, the test load is 200g; the measured bending resistance is 45 times. According to the design of the standard MIT serpentine line, the bending test area (referring to the bending test area of the standard MIT serpentine test line, where the line breaks and fails): the width of the standard sample is 15mm, and the length of the bending test line area 3.75mm, the line width of the bending test area is 12um, and th...

Embodiment 2

[0055] A calculation method for the number of bending resistance of finished COF Film prepared by B company base material (the base material provided by B company), comprising the following steps:

[0056] S1: Take the base material provided by Company B (the base material provided by Company B) and go through the existing COF Film process to prepare a standard MIT serpentine test circuit, and take a standard circuit with a line width of 12um and a pitch of 22um for bending resistance test .

[0057] S2: The bending resistance test method refers to the test method in the international standard JIS P8115, the test load is 200g, and the measured bending resistance is 65 times. According to the design of the standard MIT serpentine line, the bending test area (referring to the bending test area of the standard MIT serpentine test line): the width of the standard line is 15mm, the length of the bending test line area is 3.75mm, and the bending test area The line width is 12um, ...

Embodiment 3

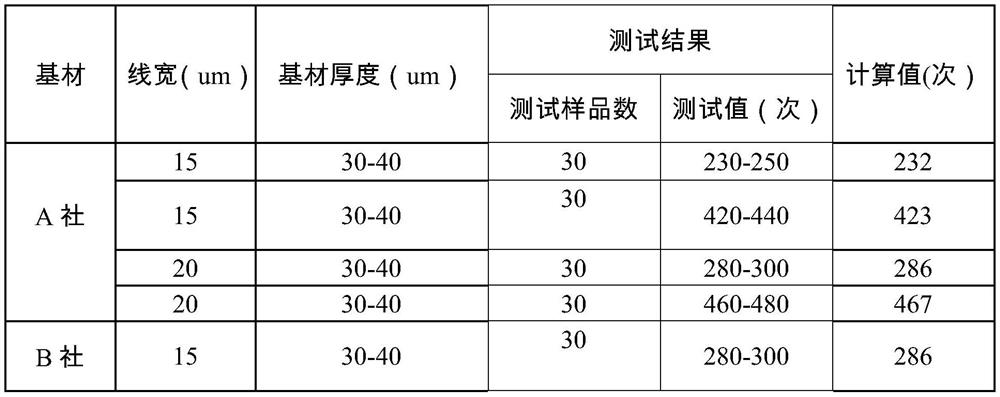

[0076] After the COF Film finished product is bent for a certain number of times by a bending tester, observe whether the circuit breaks through a metallographic microscope, and compare the result with the calculation method of the bending resistance test of the finished COF Film of the present invention (embodiment 1 and embodiment 1). 2) The calculated values of the finished COF Film products are compared, and the results are shown in Table 1 below.

[0077] Table 1

[0078]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap