Preparation method of water-permeable concrete

A concrete and water-permeable technology, applied in chemical instruments and methods, ceramic products, filter screens, etc., can solve the problems of labor-intensive manual screening, reduced stone screening efficiency, and inability to transport stones, etc., to improve screening. The effect of quality and efficiency, reducing labor intensity and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be embodied in various ways of claims defined and covered.

[0032] like Figure 1 to 9 As shown, a permeable concrete preparation method mainly includes the following steps:

[0033] Step 1, the screening operation, transport the stone into the stone screening equipment for screening operations to obtain a small particle size;

[0034] Step 2, the raw material ratio, prepare cement, cement, water reducer, reinforcing agent, water water, water and step, and obtain the raw materials required for water-watering concrete production;

[0035] Step three, stirring, the raw materials required for the preparation of water-based concrete production in steps are sequentially added to the mixer for stirring, resulting in a uniform water-water concrete.

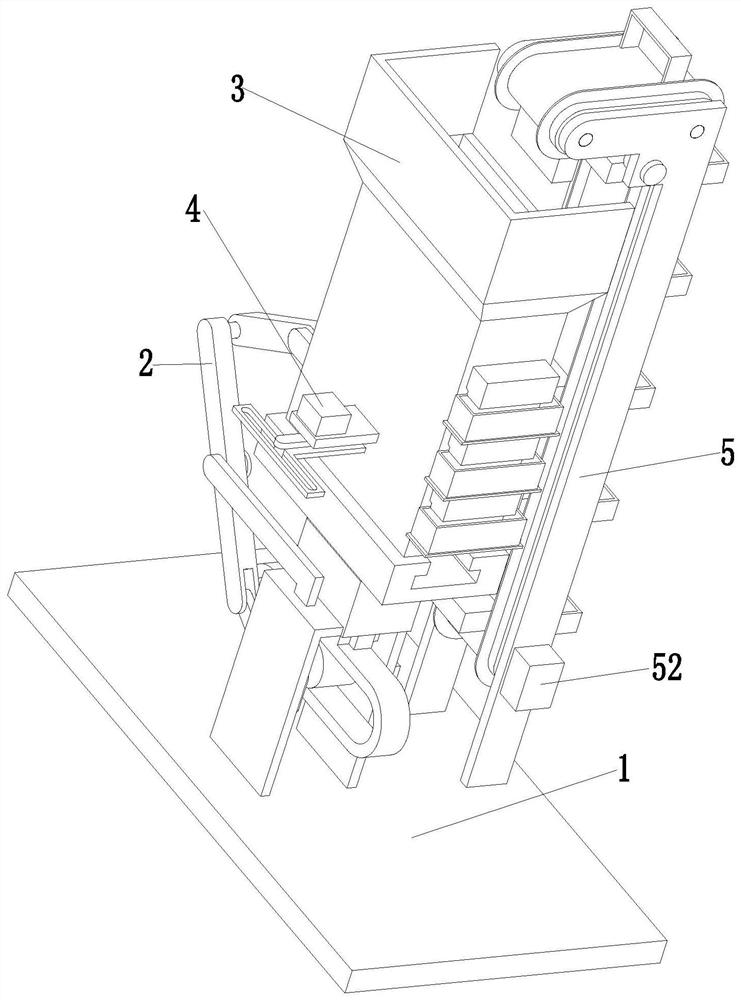

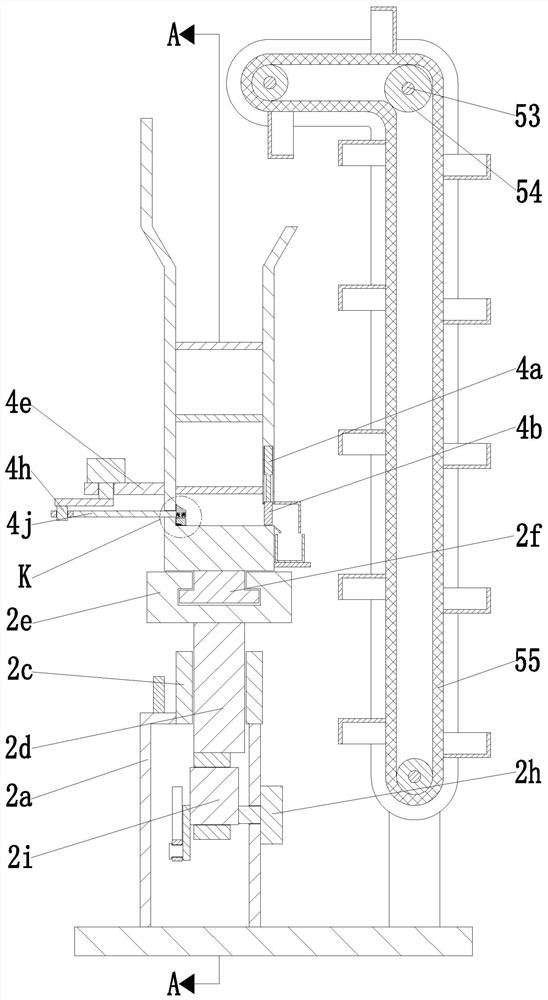

[0036] The stone screening apparatus used in the above step includes the bottom plate 1,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap