Toughness composite buffer for slope flexible protection system and design method of toughness composite buffer

A flexible protection and composite buffering technology, applied in excavation, special data processing applications, geometric CAD, etc., can solve problems such as unreasonable setting of buffer mechanism, troublesome maintenance of energy consumers, not economical and reasonable, etc., to avoid braking effect, The structure is simple and the effect of reducing abnormal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

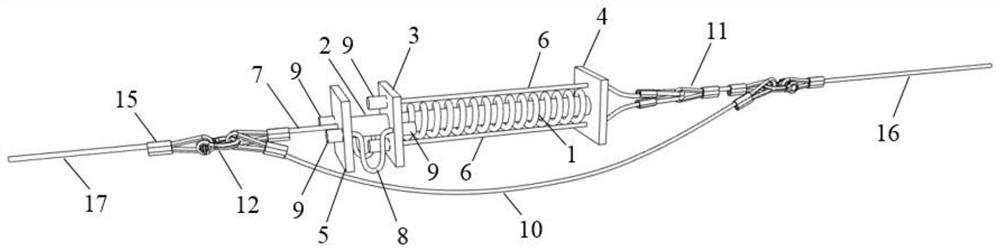

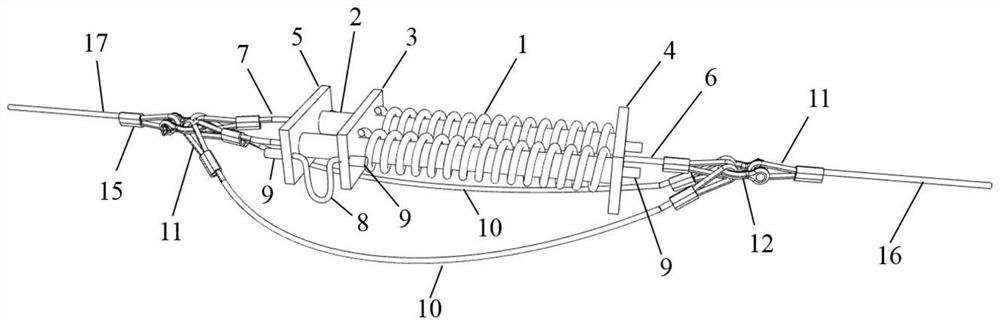

Embodiment 1

[0097] This embodiment intends to design a flexible composite buffer applied to the small energy level flexible protection system. According to the recommendation of the specification, the spring steel material grade is 60Si2Mn, and the steel pipe material is Q235 steel. The flexible composite buffer described in this embodiment adopts a buffer spring, and each plate and each connecting member is adjusted accordingly according to the design, such as figure 1 shown.

[0098] according to figure 1 Computational design is performed as shown in the design flow:

[0099] According to the existing experiments and numerical simulations, determine the tension F of the support rope in normal use sel =30kN

[0100] According to the demand, the maximum deformation of the preset spring is s=250mm

[0101]Preliminary design and determine the number of springs m = 1

[0102] To calculate the spring bar diameter d, use the equation Carry out the calculation, refer to the specification an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap