Wall facing mortar as well as preparation method and use method thereof

A technology for facing mortar and wall body, which is applied in the field of building wall decoration materials, can solve the problems of poor fire resistance and poor fire resistance of facing mortar, achieve natural and beautiful decorative effect, avoid poor fire resistance and better decorative effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

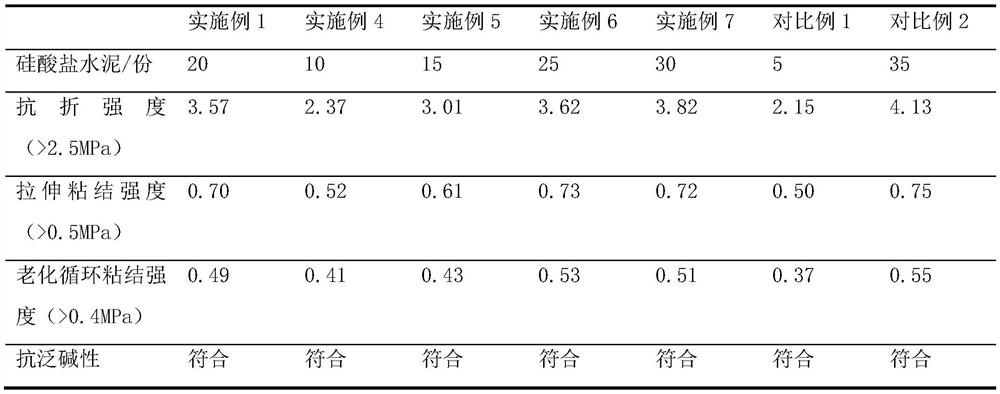

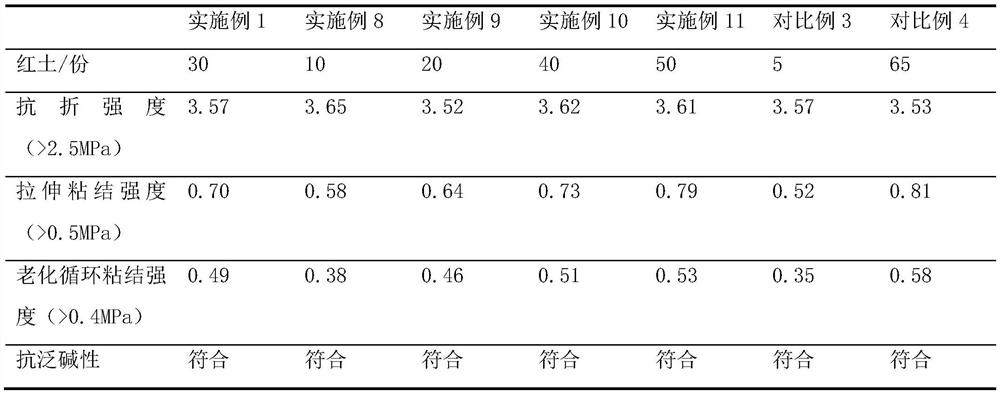

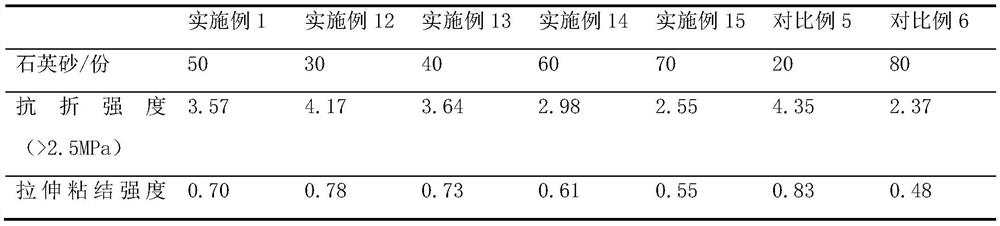

Embodiment 1

[0033] The wall finish mortar of the present embodiment comprises: in parts by weight, including: in parts by weight, 20 parts of Portland cement, 30 parts of red clay and 50 parts of quartz sand; the addition of water is Portland cement, 23% of the total mass of laterite and quartz sand.

[0034] Among them, the mesh number of quartz sand is 50 mesh.

[0035] The preparation method of the wall finish mortar of the present embodiment comprises the following steps:

[0036] (1) Stir and mix the laterite and quartz sand evenly, add portland cement and stir and mix evenly to obtain the mixture, put it into a moisture-proof bag, and seal it for later use;

[0037] (2) Stir and mix the mixture with water, and obtain the wall facing mortar after fully stirring;

Embodiment 2

[0039] The proportioning of the wall facing mortar of this embodiment is the same as that of Example 1, the difference is that the preparation method is different, specifically as follows:

[0040] (1) Stir and mix the laterite and quartz sand evenly, add portland cement and stir and mix evenly to obtain the mixture, put it into a moisture-proof bag, and seal it for later use;

[0041] (2) Stir and mix the mixture with water, and obtain the wall facing mortar after fully stirring;

[0042] Example 2:

[0043] The proportioning of the wall facing mortar of this embodiment is the same as that of Example 1, the difference is that the preparation method is different, specifically as follows:

[0044] (1) Stir and mix the laterite and quartz sand evenly, add portland cement and stir and mix evenly to obtain the mixture, put it into a moisture-proof bag, and seal it for later use;

[0045] (2) Stir and mix the mixture with water, and obtain the wall facing mortar after fully stirring;

Embodiment 4

[0047] The preparation method of the wall finish mortar of this embodiment is the same as that of Embodiment 1, the difference is that the proportion of Portland cement is not used, and the addition amount of Portland cement is 10 parts, and other components are the same.

[0048] It includes: by weight, 10 parts of Portland cement, 30 parts of red clay and 50 parts of quartz sand; the amount of water added is 23% of the total mass of Portland cement, red clay and quartz sand.

[0049] Among them, the mesh number of quartz sand is 50 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap