Barrel type hydraulic shock absorber of automobile

A hydraulic shock absorber, barrel-type technology, applied in the direction of shock absorber, liquid shock absorber, spring/shock absorber, etc., can solve the problems of fast damping attenuation and slow recovery speed, so as to improve the effect of damping and shock absorption, Improve the damping recovery speed and avoid the effect of damping attenuation too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

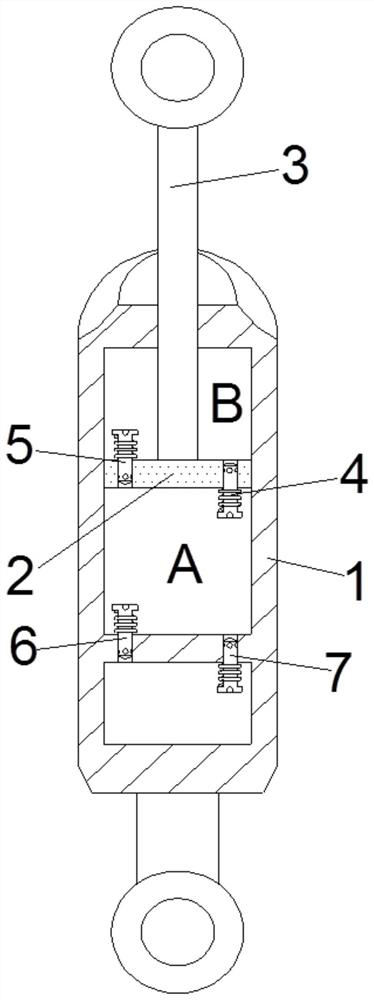

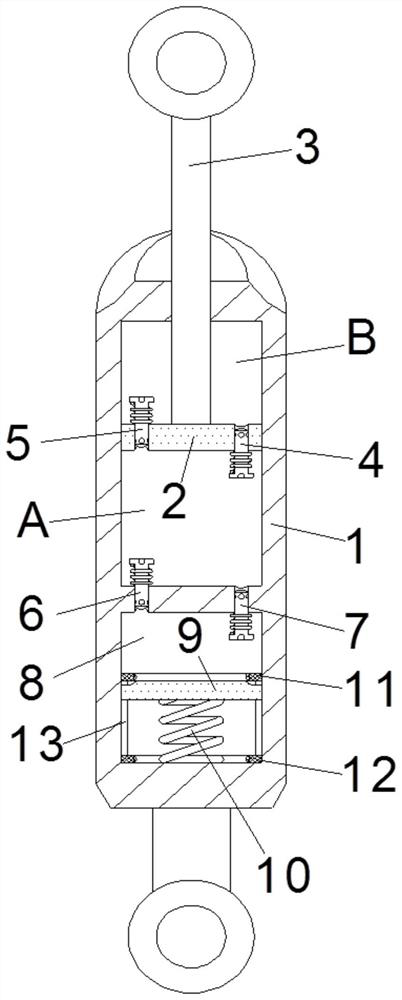

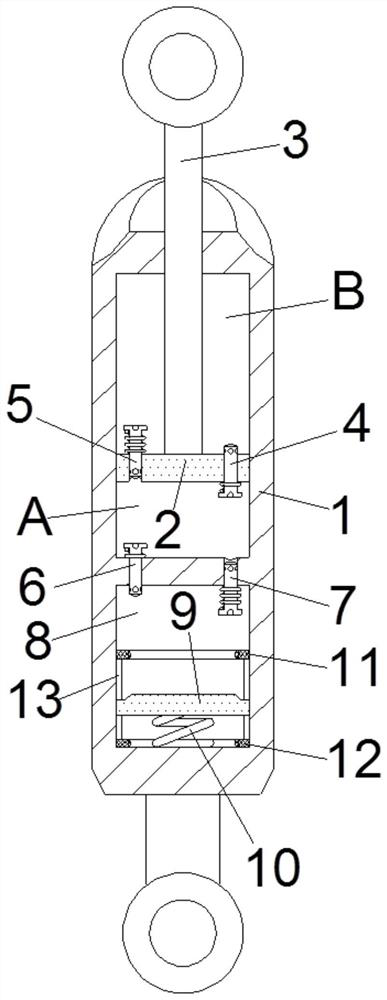

[0021] Such as figure 2 As shown, an automobile cylinder type hydraulic shock absorber of the present invention comprises an axially vertical hydraulic cylinder block 1, and a partition plate is arranged in the hydraulic cylinder block 1 to divide the interior of the hydraulic cylinder block 1 into upper and lower sections. The interior of the hydraulic cylinder 1 above the plate is used as a working chamber filled with hydraulic oil, and the interior of the hydraulic cylinder 1 below the partition is used as a pressure relief compensation chamber 8 .

[0022] The first piston 2 is vertically slid in the working chamber. The first piston divides the working chamber into the lower part A of the working chamber and the upper part B of the working chamber. Body, the bottom of the hydraulic cylinder block 1 is connected to the automobile suspension. The fir

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap