Offshore wind power negative pressure barrel base hydraulic device and control method

A hydraulic device, offshore wind power technology, applied in wind power generation, monitoring of wind turbines, and configuration of installation/support of wind turbines, etc. Automatic positioning, easy to use and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

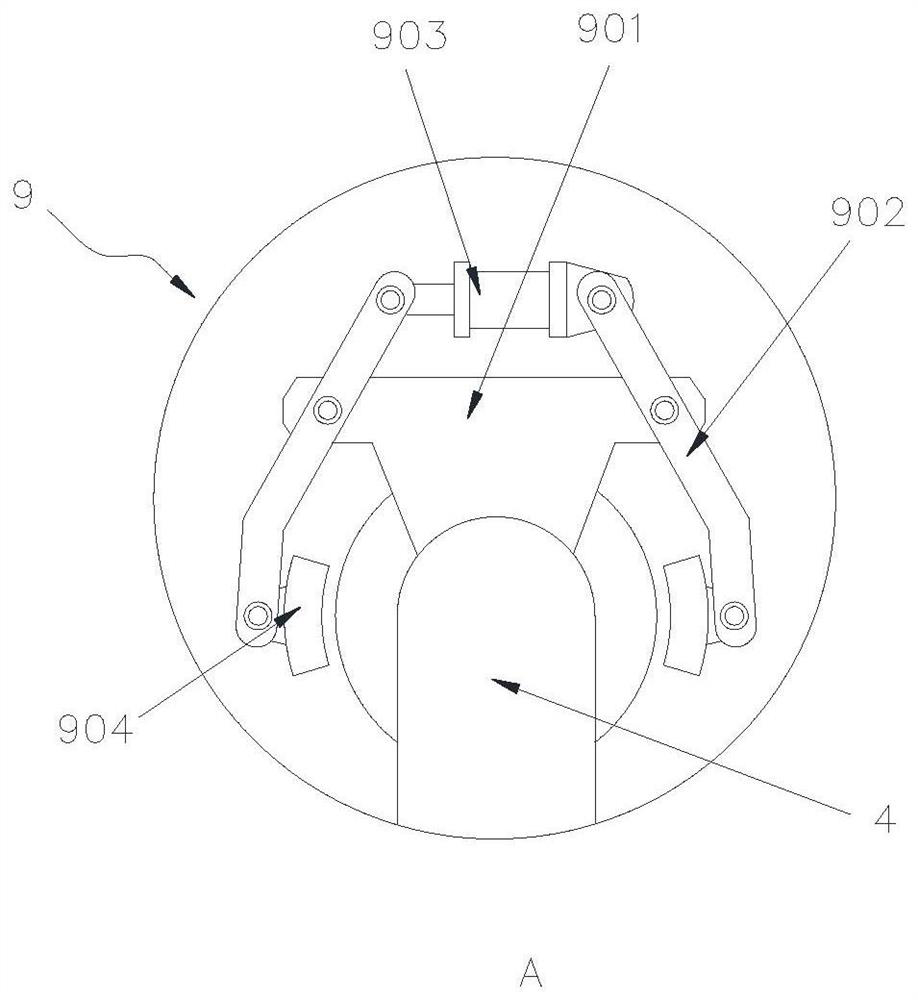

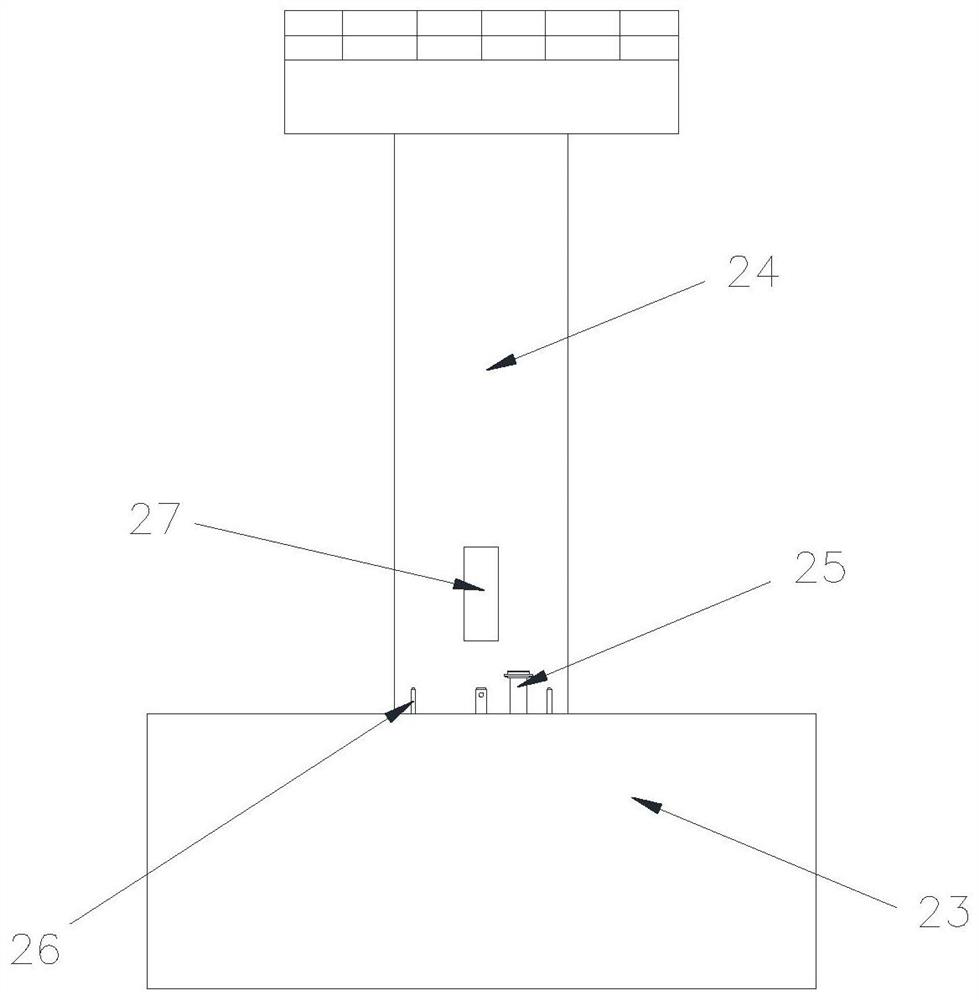

[0040] refer to figure 1 with figure 2 , an offshore wind power negative pressure barrel base hydraulic device, including a frame 1, a bidirectional suction pump 2, a suction pipe 3, a delivery pipe 4 and a discharge pipe 5 are mounted on the frame 1. Wherein, one end of the suction pipe 3 is connected with one end of the suction pump 2, and the other end of the suction pipe 3 is used to communicate with the sea water outside the negative pressure barrel; one end of the delivery pipe 4 is connected with the other end of the suction pump 2, The other end of delivery pipe 4 is used to be connected with the docking pipe 25 on the negative pressure barrel; one end of discharge pipe 5 communicates with the middle section of delivery pipe 4, and the other end of discharge pipe 5 is used for discharging the seawater in the negative pressure barrel.

[0041] A first control valve 6 is installed on the discharge pipe 5 , and the first control valve 6 is used to control the on-off of the

Embodiment 2

[0068] A method for controlling the hydraulic device of an offshore wind power negative pressure barrel base, specifically, when sinking into the base:

[0069] S1. Lock the hydraulic device and the negative pressure barrel together through the automatic locking mechanism, and complete the docking of the delivery pipe of the hydraulic device and the docking pipe of the negative pressure barrel, and connect the hydraulic device with the control equipment on the ship through cables;

[0070] S2. Open the first control valve and close the second control valve, lift the negative pressure barrel into the air and lower it slowly by the lifting equipment on the construction ship, so that the negative pressure barrel slowly sinks into the seabed. When the negative pressure barrel reaches the seabed, the bottom of the negative pressure barrel Buckle the seabed, so that the inside of the negative pressure barrel forms a sealed space, and then the negative pressure barrel sinks to a certain

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap