Label welding manipulator

A technology for welding manipulators and signs, which is applied in the direction of manipulators, welding equipment, auxiliary welding equipment, etc., can solve the problems of high surface temperature of steel billets, mixed steel of labels and billets, and complicated welding process, so as to reduce production costs, improve work efficiency, The effect of avoiding safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] combine Figure 1-8 The structure and operation of the present invention are described.

[0019] Taking the production of special steel bars as an example, in the end face welding station of bundled bars in the special steel bar finishing production line, the label welding manipulator is applied to the label welding robot system to realize automatic label welding.

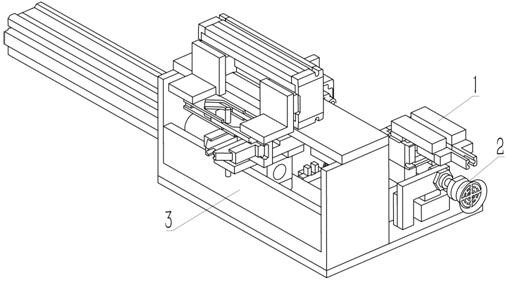

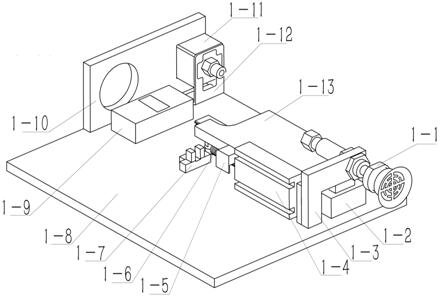

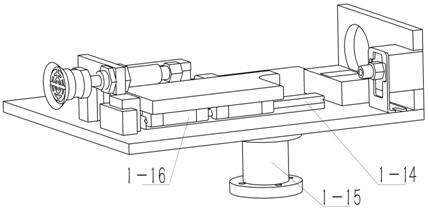

[0020] The sign welding manipulator is installed at the end of the industrial robot, and automatically completes the actions of grabbing the welding stud and the sign, welding the welding stud and breaking off the tail of the excess welding stud, including the sign suction mechanism 1, the clamp welding mechanism 2 and the swing breaking nail Institution 3. The label suction mechanism 1 is fixedly connected with the end of the industrial robot 4 through the flange, the nail clip welding mechanism 2 is installed on the label suction mechanism 1, and the swing nail breaking mechanism 3 is installed on one side o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap