Counterbalanced forklift truck multi-way valve control mechanism arranged in front right area of driver

A control mechanism and multi-way valve technology, applied in the field of forklifts, can solve the problems of complex transmission route, large space occupation, long arm extension time, etc., and achieve the effect of accurate transmission route, simple mechanism and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

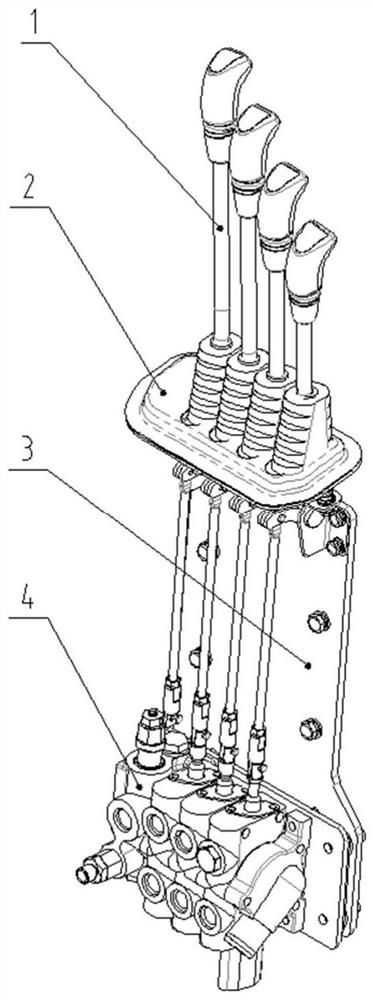

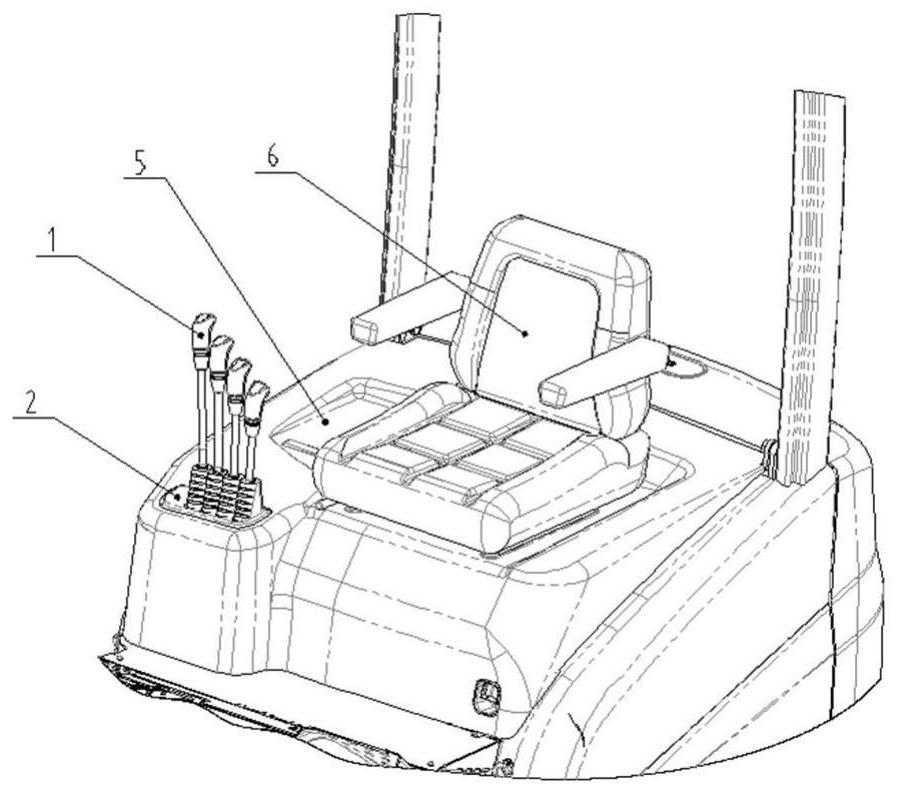

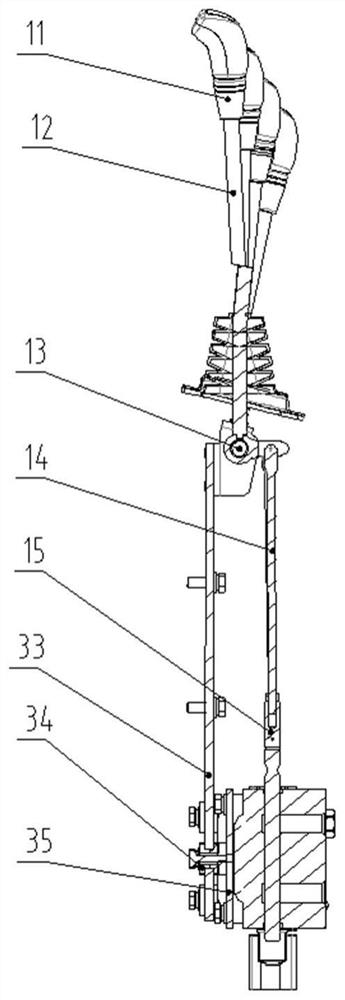

[0027] Further detailed description of the technical solutions of the present invention will be described below with reference to the drawings:

[0028] Description of the present invention, it is to be understood that the orientation or positional relationship between the terms "left", "right", "upper", "lower", etc., indicate the orientation or positional relationship as shown in the accompanying drawings, only to facilitate the description of the invention and to simplify the description, but does not indicate or imply that the device or element referred to must have a particular orientation, the orientation of a particular configuration and operation, "first", "second" etc. do not denote parts importance, can not be construed as limiting the present invention. Specific dimensions employed in the present embodiment only to illustrate the technical solution, and do not limit the scope of the present invention.

[0029] The present invention provides a loader mechanism for actuating

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap