Embedded metal bottle opening structure of IV-type hydrogen storage bottle

An embedded, hydrogen storage bottle technology is applied in the manufacture of container structures, fixed-capacity gas storage tanks, installation devices for container structures, etc. The sealing effect needs to be strengthened to achieve the effect of dispersing stress concentration, strong impact resistance and good lateral impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

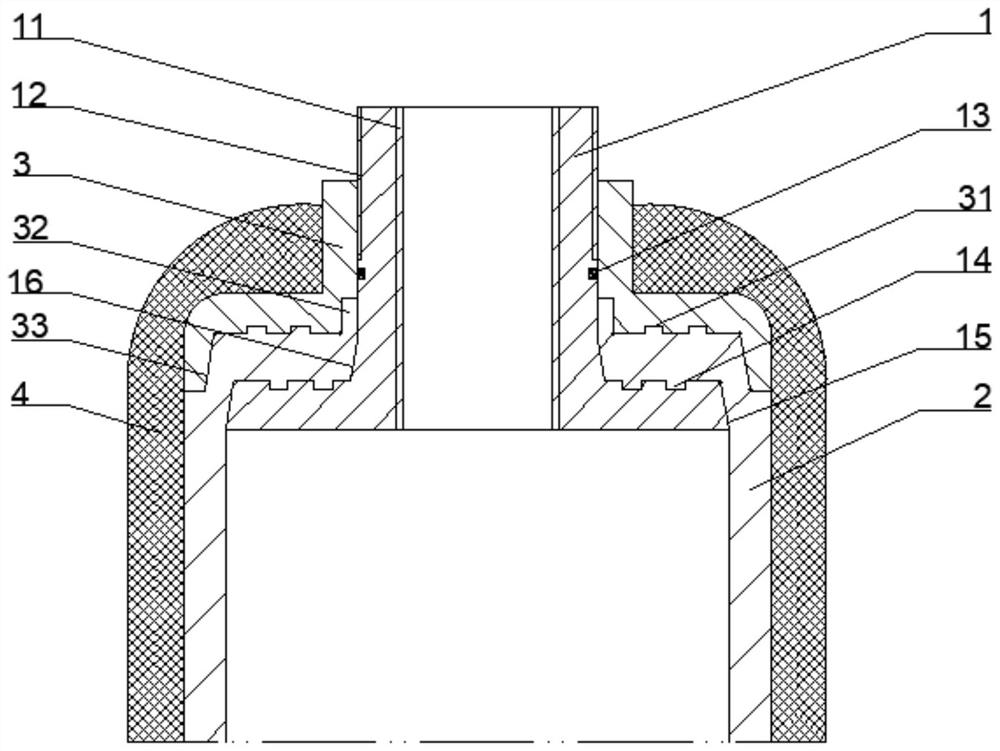

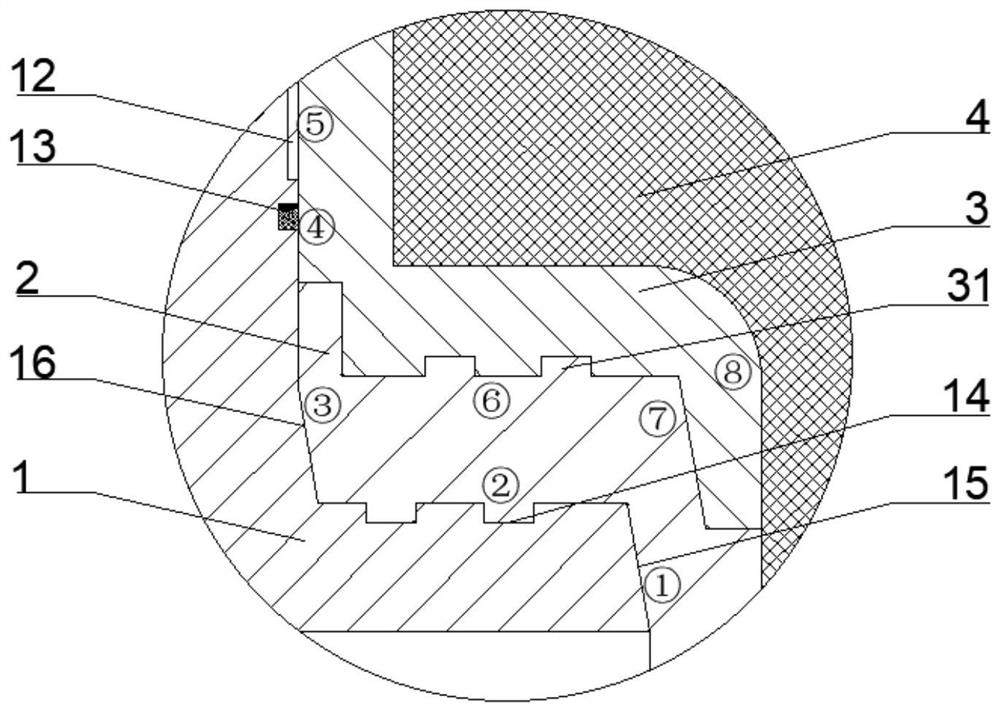

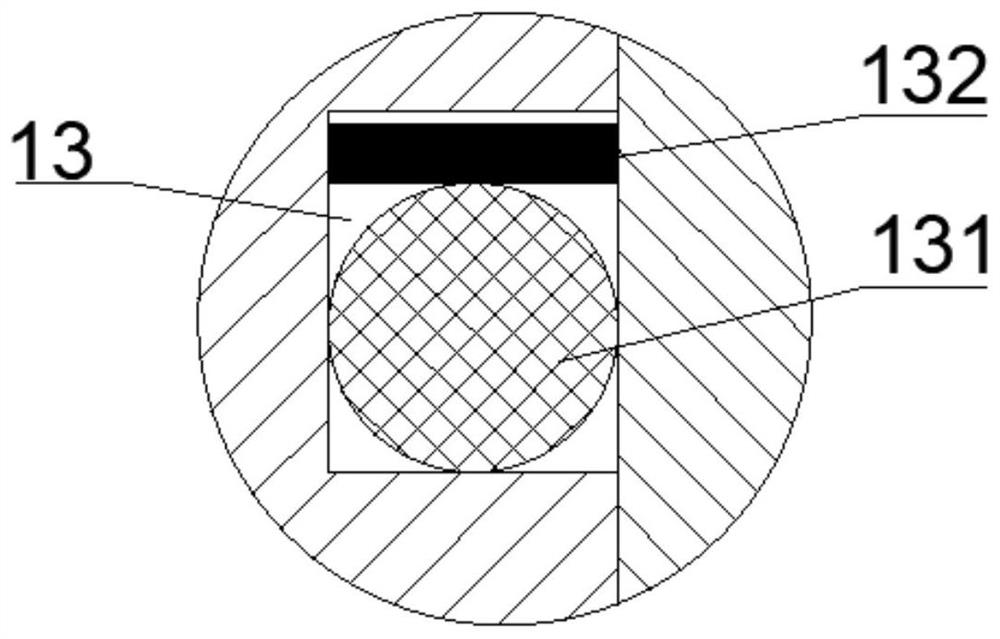

[0033] Embodiment 1 The type IV hydrogen storage bottle embedded metal bottle mouth structure of the present invention includes a valve seat 1 , a plastic liner 2 , a gland 3 and a winding layer 4 . The valve seat 1 has a vertical valve seat bottleneck and a horizontal valve seat shoulder, and the valve seat neck cone 16 transitions between the valve seat bottleneck and the valve seat shoulder, and the valve seat bottleneck has a hollow inner hole, which will be close to The direction of the central axis of the inner hole is located inside, and the direction away from the central axis is outward; the inner hole of the valve seat 1 is provided with an internal thread 11 . Valve seat 1 is connected with bottle valve by internal thread 11. The outer cylindrical surface of the bottleneck of the valve seat is provided with an external thread 12 and a sealing groove 13 . The outer edge of the valve seat shoulder is provided with a valve seat shoulder taper surface 15 .

[0034] The g

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap