Ultrasonic detection device for flashes of molded composite product and control method

A technology of ultrasonic detection and control method, applied in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, etc. Visually observe the problems of flashing of molded products, and achieve the effect of quick installation and disassembly, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example 1:

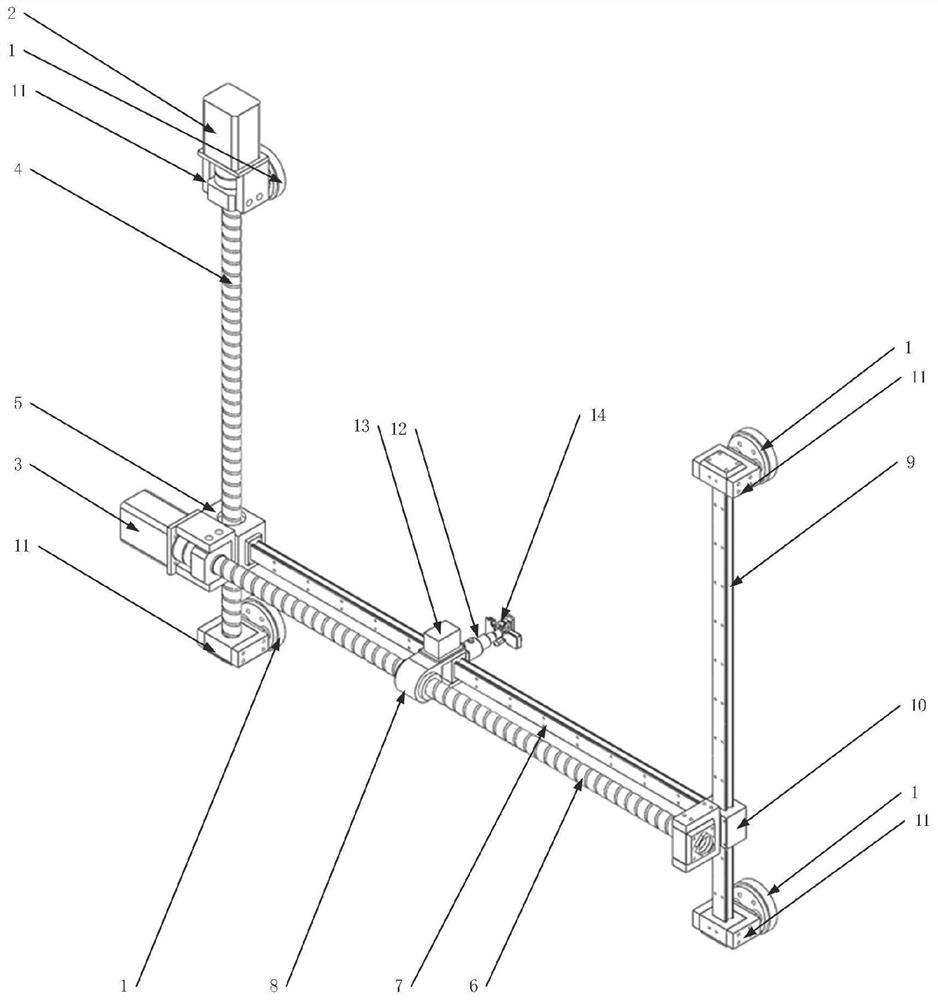

[0033] The whole set of testing equipment includes a controller, a molding machine 16, a mold 15 and an ultrasonic testing device, among which:

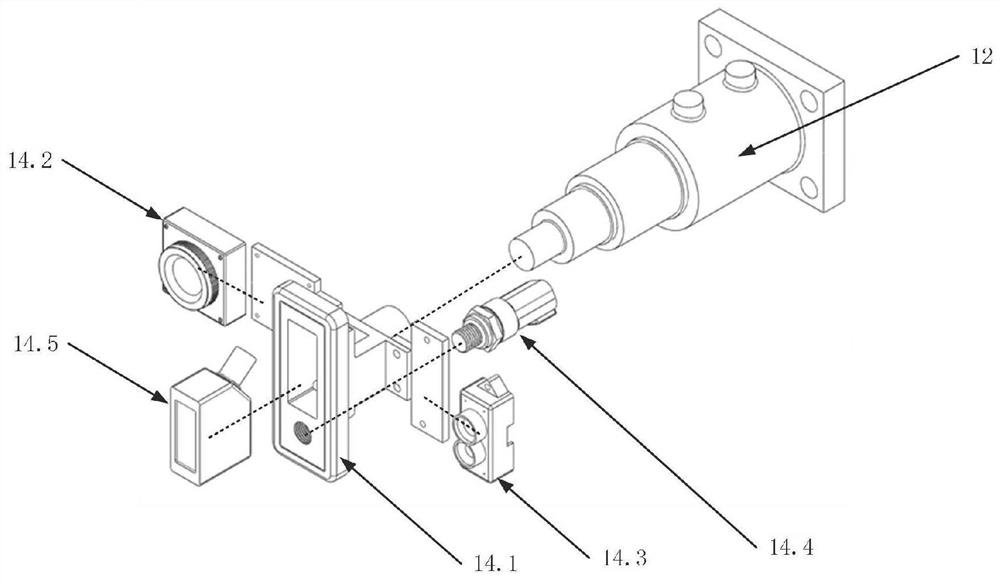

[0034] The controller includes a STM32 single-chip microcomputer, which can realize the communication with the visual positioning sensor 14.2, the distance sensor 14.3, and the pressure sensor 14.4, and control the vertical screw servo motor 2, the horizontal screw servo motor 3 and the automatic spraying coupling fluid mechanism. 13 to take control.

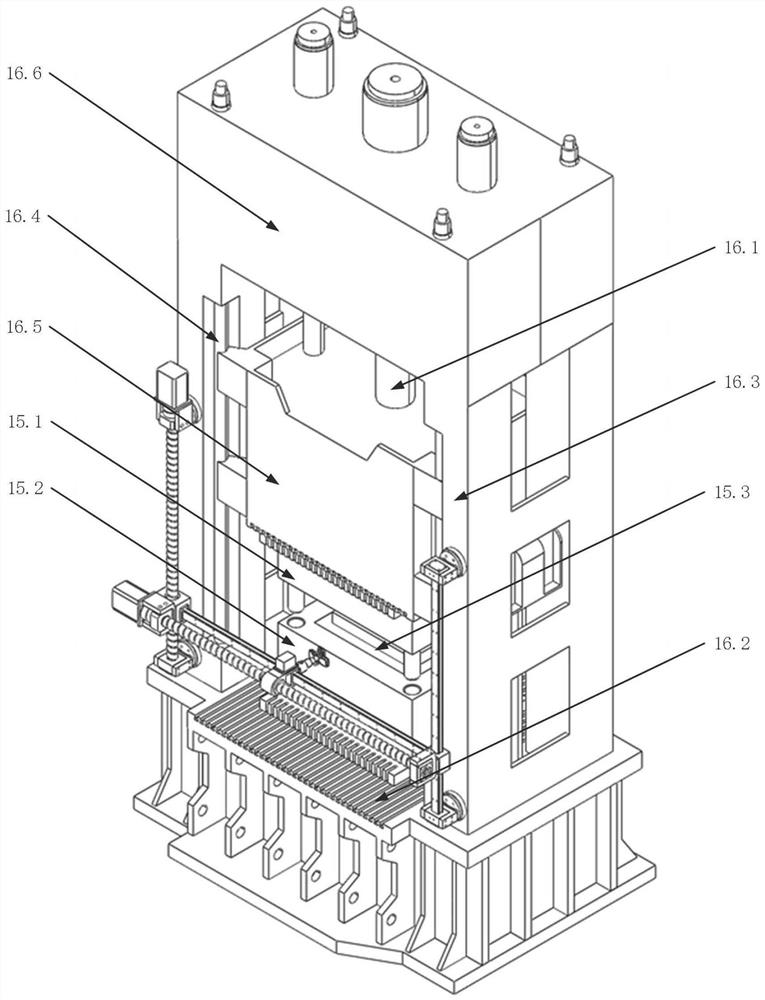

[0035] The mold 15 includes an upper mold 15.1, a lower mold 15.2, a molding cavity 15.3 and a heating oil heat conduction channel 15.4, and the composite material product 15.5 is obtained through the mold, and the composite material product 15.5 will produce flash 15.6 during the pressing process.

[0036] The molding press 16 is mainly composed of a hydraulic cylinder 16.1, a workbench 16.2, a column 16.3, a guide rail 16.4, a middle beam 16.5, and an upper beam 16.

Example Embodiment

[0065] Embodiment 2:

[0066] The structure of the entire set of testing equipment is the same as that of the first embodiment, but the control methods are different. In this embodiment, during the ultrasonic testing in step S4, the ultrasonic installation assembly will continue to test back and forth until the flash is detected or the pressure holding time t1 is reached.

Example Embodiment

[0067] Embodiment three:

[0068] The structure of the whole set of detection equipment is the same as that of the first embodiment, but its control methods are different. In this embodiment, the echo signal is obtained when the flash edge is detected in step S3, and then the pressure holding time t1 is adjusted according to the size of the echo signal, that is, if If the echo signal has no flash at all, the dwell time will not be changed. If the echo signal indicates that there is a certain flash, but the critical flash threshold has not been reached, the dwell time t1 can be reduced appropriately.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap