Fire extinguishing device of oil field heating furnace

A technology of fire extinguishing device and heating furnace, which is applied in the control of fluid heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as difficulty in extinguishing fire with torches and fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

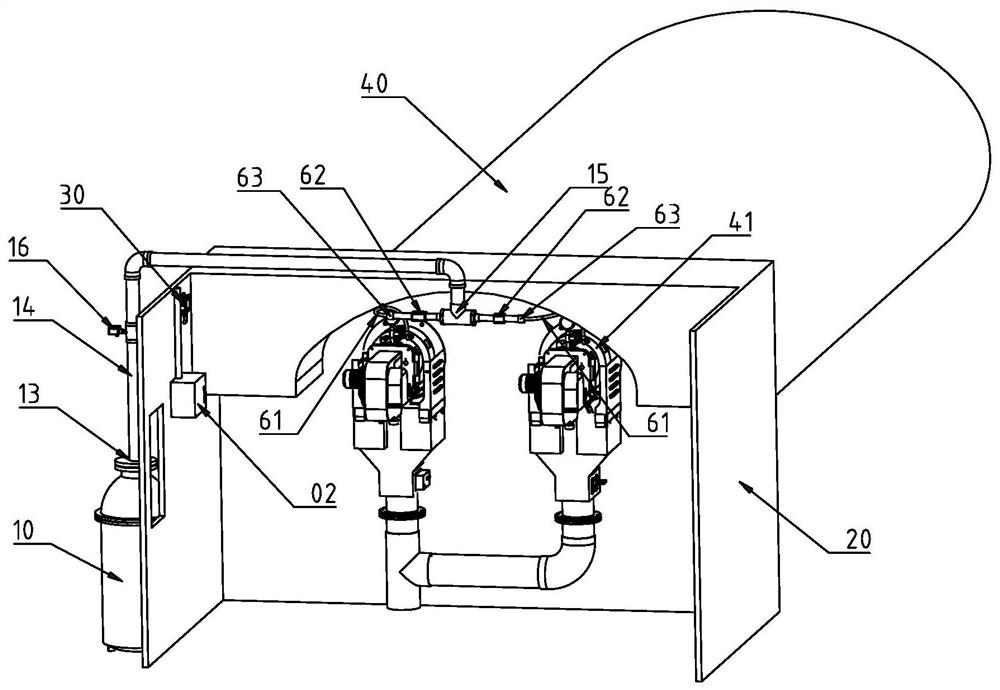

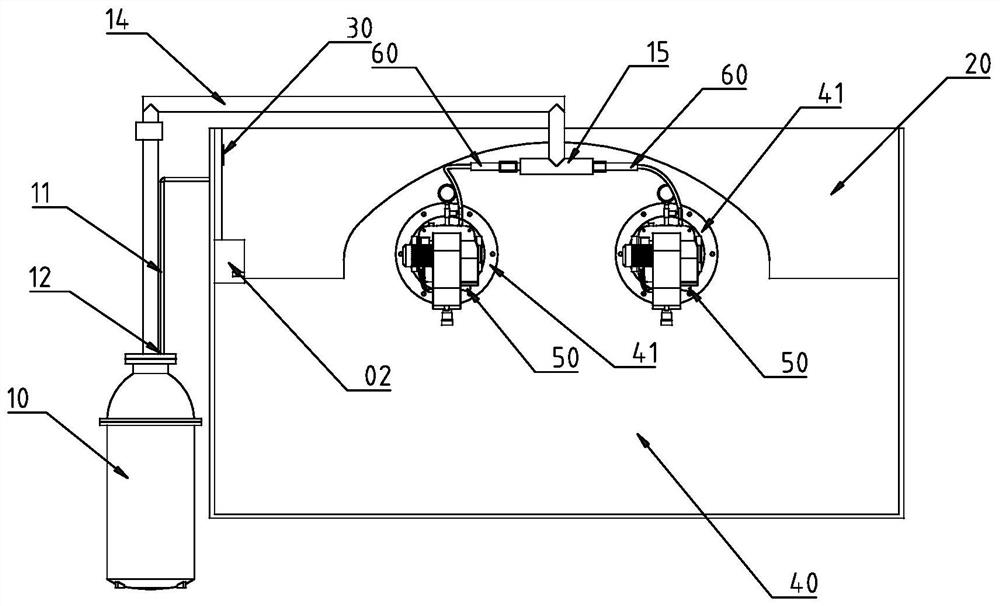

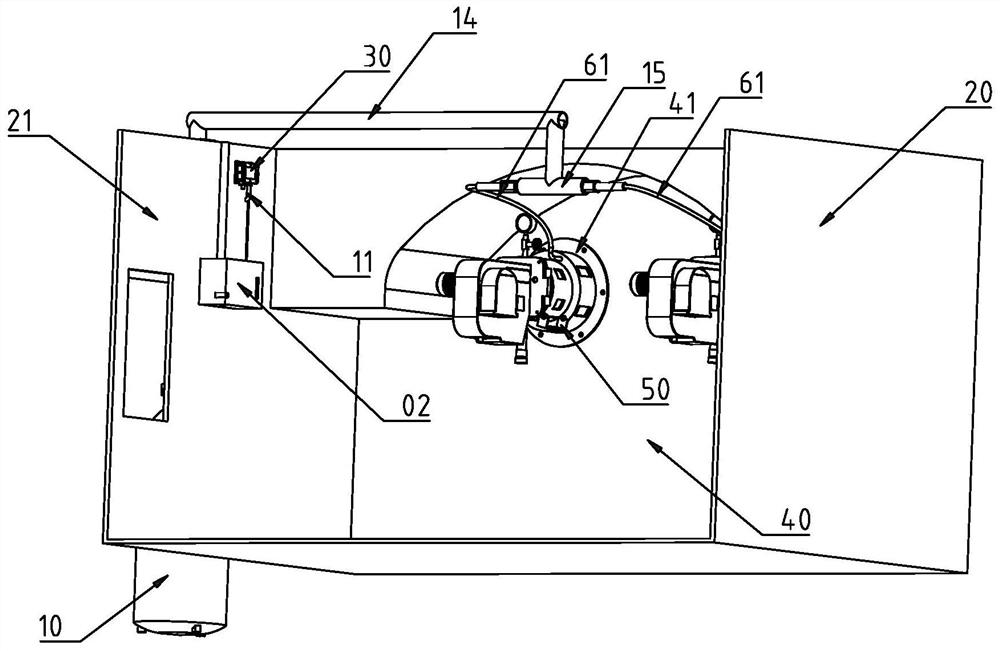

[0027] The structure of the oil field heating furnace fire extinguishing device of the embodiment of the present invention is as follows: Figure 1 to Figure 6 As shown, it includes a smoke generator 10 as a fire extinguisher, a control circuit, a main pipeline 14 for delivering smoke, a three-way joint 15 and two torch fire extinguishing units 60 . The oil field heating furnace 40 generally has two torches, so two torch fire extinguishing units 60 need to be equipped.

[0028] The gas fire extinguishing medium generator can also use trifluoromethane (nitrogen) generator, carbon dioxide generator, heptafluoropropane generator or perfluorohexanone generator, and the gas fire extinguishing medium generator in this embodiment is described by taking smoke generator as an example.

[0029] Each torch fire extinguishing unit 60 includes a branch pipeline 61, an electric control valve 62, a flash pressure sensor 63, a liquid leakage detection sensor 50 and an image video flame recognize

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap