Laser drilling hidden crack testing method for MWT battery

A technology of laser drilling and testing methods, which is applied in optical testing flaws/defects, semiconductor/solid-state device testing/measurement, circuits, etc., which can solve the problems of batch defective products flowing into subsequent processes, and inability to directly judge silicon wafer cracks. , to achieve the effect of preventing the use of hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, those of ordinary skill in the art will belong to the scope of the present invention in the scope of the present invention without making creative labor premises.

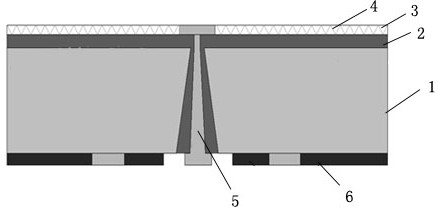

[0015] The MWT battery prepared by the production of the present invention figure 1 As shown, the front surface of the substrate 1 is provided with the n emitter 2 and the SiNx reduction membrane 3, and the Sinx reduction film 3 is distributed on the bone line 4, and the back surface of the substrate is coated with an aluminum back field 6.

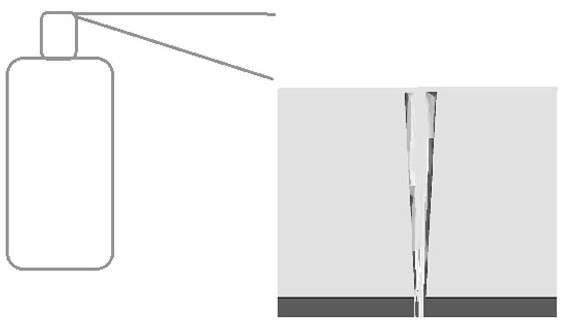

[0016] The present invention employs a laser punching, a back-wiring technique to eliminate the main gate line of the front elec

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap