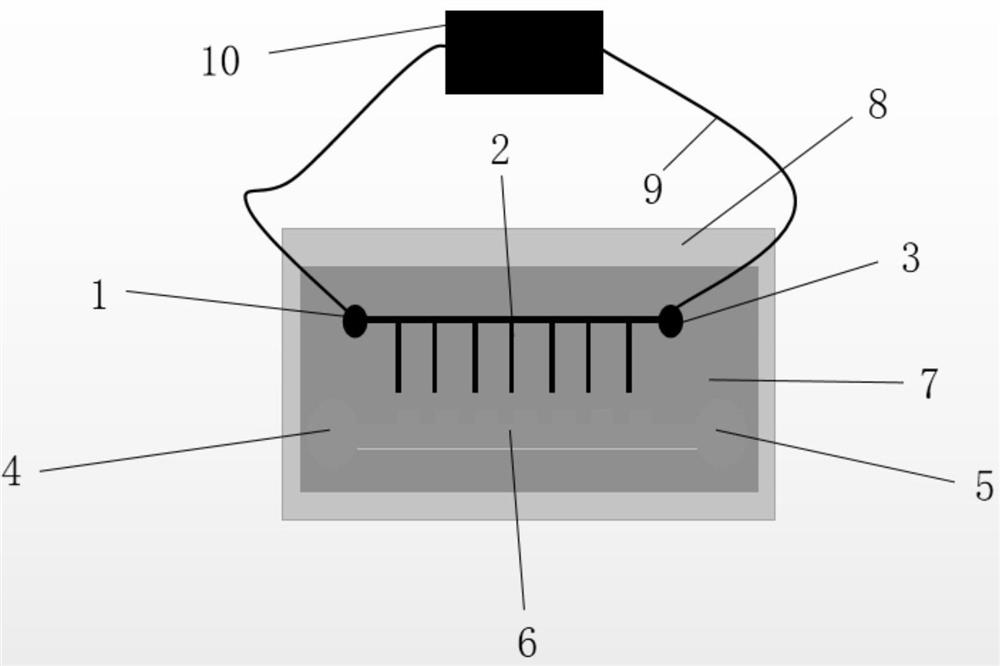

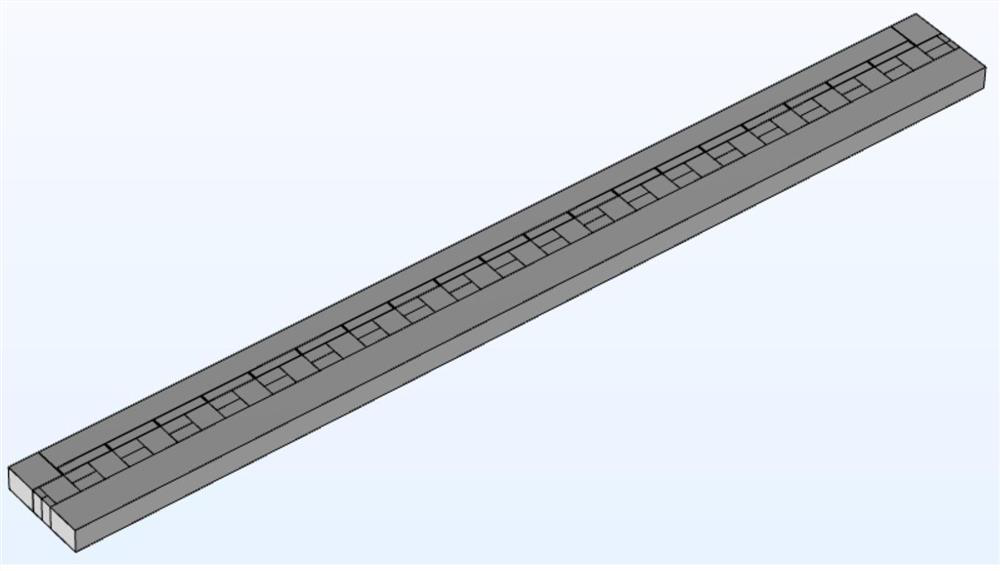

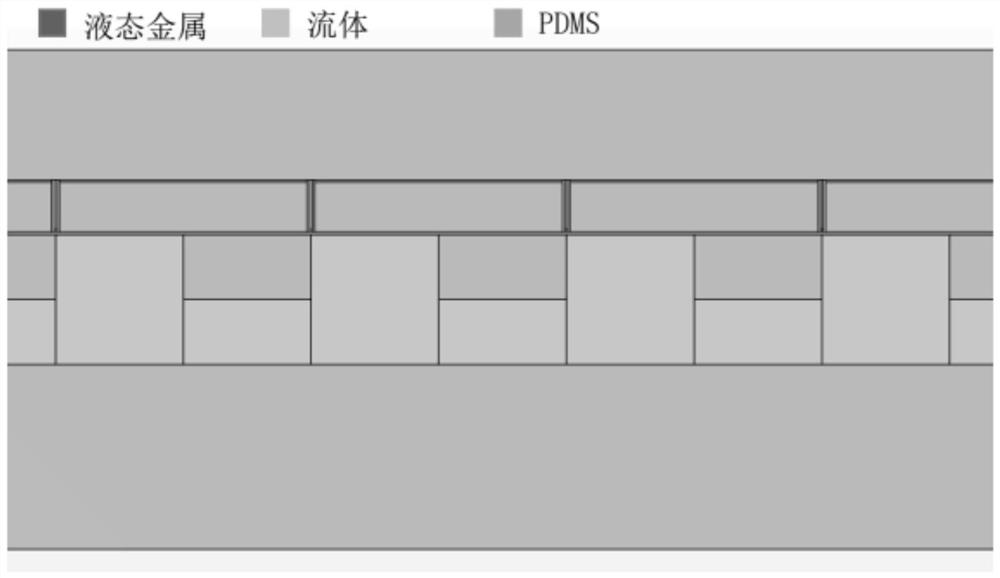

Device for controlling liquid to flow directionally under heating condition in pipeline of micro-fluidic chip

A microfluidic chip and directional flow technology, applied in fluid controllers, heating or cooling equipment, laboratory containers, etc., can solve the problems of liquid drive technology limitations, large equipment quality and volume, and high cost of pumping technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The manufacturing method of the device for controlling the directional flow of liquid by the internal heating conditions of the pipeline of the microfluidic chip disclosed in this embodiment is as follows:

[0029] Step 1: Preparation of the microfluidic chip.

[0030] According to the biochemical reaction at the micro-nano scale to provide the reaction environment requirements, the structure of the pipeline in the microfluidic chip is designed in AutoCAD and other image design software, so that it has periodic changes. Then, according to the design drawing, the mask required by the soft lithography technology is manufactured, and the silicon wafer containing the pipeline design is manufactured through the soft lithography technology. By way of reverse molding, the pattern of the silicon wafer is printed to become a PDMS pipe, which is then cut and bonded to a glass plate using plasma processing technology to obtain a microfluidic chip with the required structure.

[0031

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap