Vertical high-speed ejection device for ice crystal impact test

A technology of ejection device and impact test, which is applied in the direction of measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings.

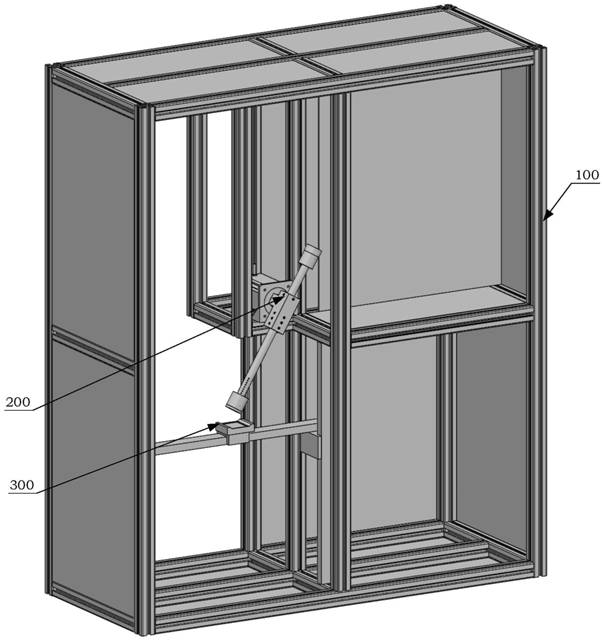

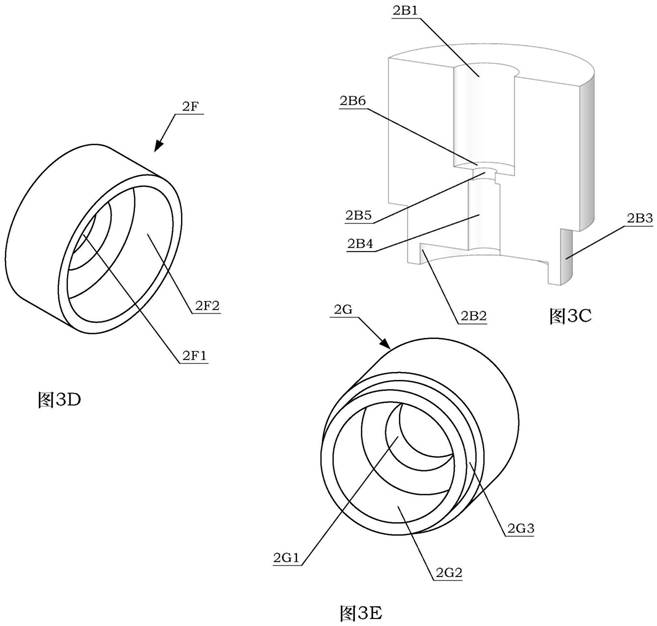

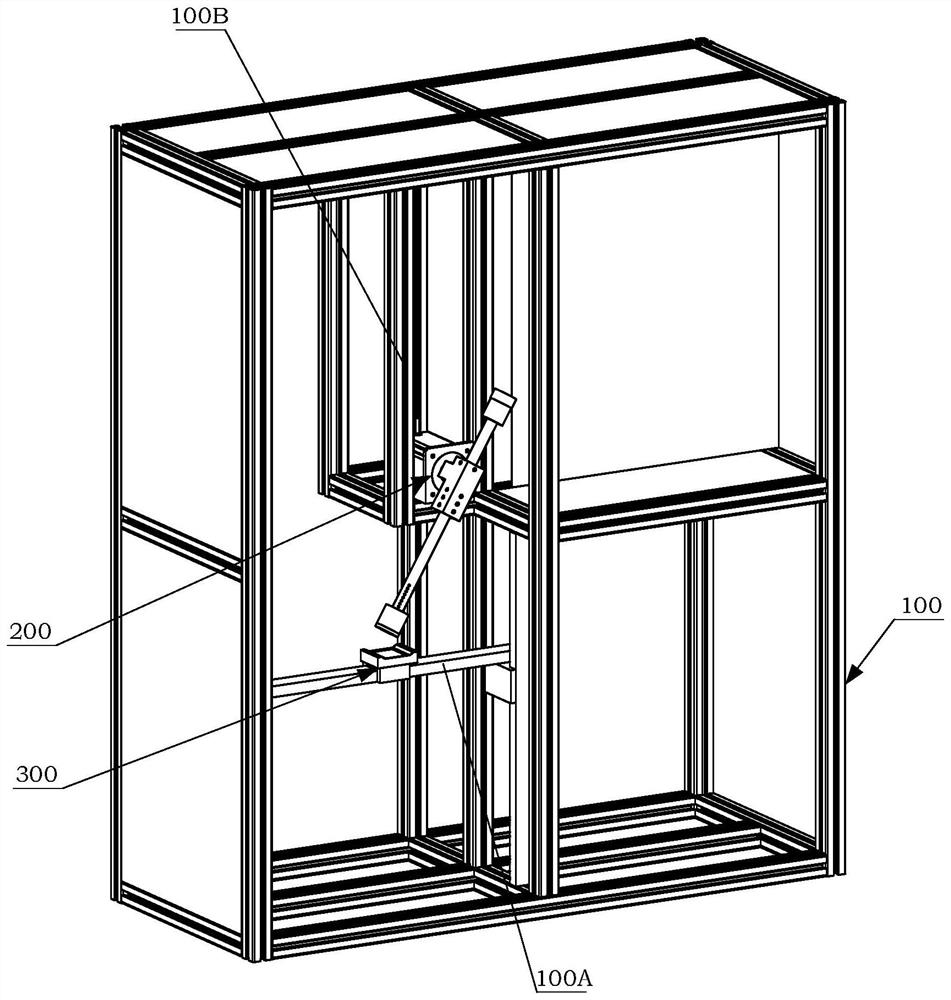

[0055] see figure 1 , Figure 1A , Figure 1B , Figure 1C As shown, an ice crystal impact test bench of the present invention includes a frame structure 100 constructed of aluminum alloy profiles, a vertical high-speed ejection device 200, an impact structure 300, a cooling pipeline for providing a low temperature environment, and an impact Angle adjustment controls.

[0056] In the present invention, the cooling pipeline in the low-temperature environment is composed of a refrigeration compressor set and a copper tube radiator. The power of the refrigeration compressor is 2000W, the minimum refrigeration temperature is -30°C, and the refrigerant is Juhua R404A. In order to reduce the speed at which cold energy diffuses to the outside and ensure cooling efficiency, except for the optical path, insulation cotton is filled between the inner and outer fram...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap