Emergency stop device applied to wood processing and used for preventing cutting damage caused by blade of cutting machine

A cutting machine and blade technology, which is applied in the direction of wood processing equipment, sawing equipment, manufacturing tools, etc., can solve the problems of being unable to stop quickly and being easily damaged, so as to achieve fast stop speed, good safety and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

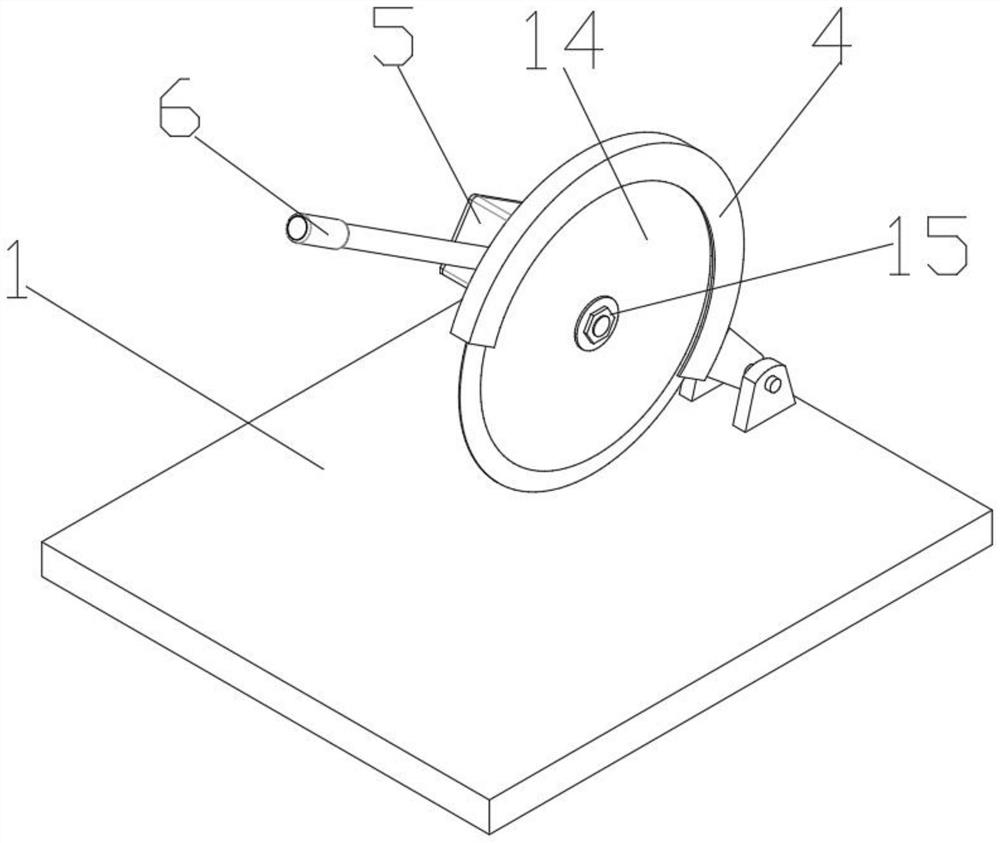

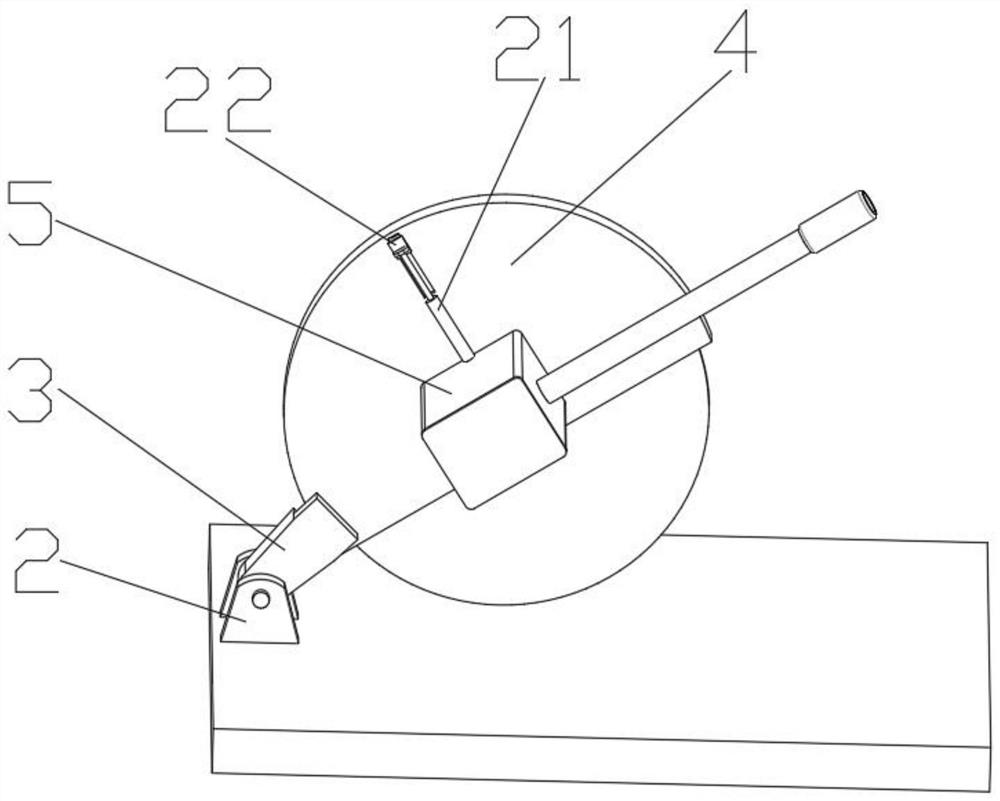

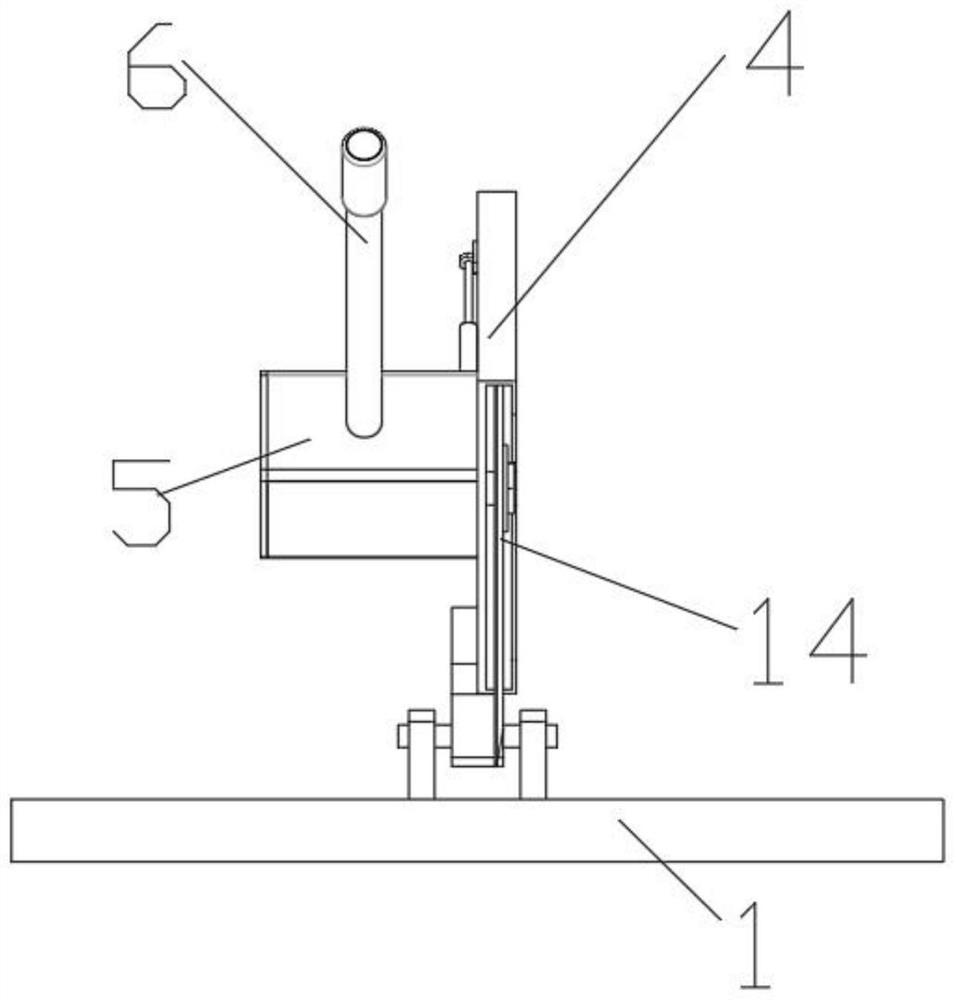

[0034] Such as Figure 1-8 As shown, the embodiment of the present invention provides a cutting machine blade anti-cut emergency stop device for wood processing, including a base 1, a mounting seat 2 arranged on the upper side of the base 1, and a torsion spring and a rotating shaft on the mounting seat 2 Rotation is provided with connecting arm 3, and the other end of connecting arm 3 is fixedly connected with cutting frame 4, and the rear wall of cutting frame 4 is fixedly provided with motor box 5 near the center, and the rear wall of motor box 5 is set to detachable, convenient to For the installation and maintenance of the internal structure, the front end of the motor box 5 is fixedly connected with the control arm 6 near the upper side.

[0035] The inner end of motor box 5 is provided with motor 7, and the inner end of motor box 5 is fixedly provided with two limit plates 8, and motor 7 is arranged between two limit plates 8, and the both sides of motor 7 and limit plate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap