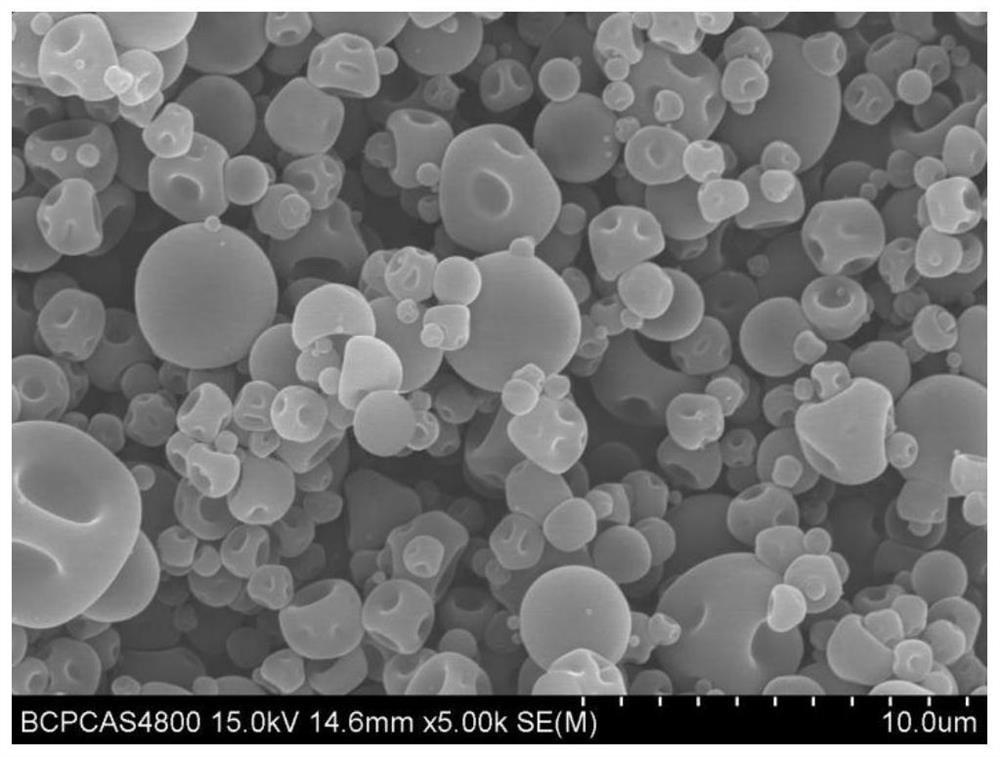

Hard carbon microspheres as well as preparation method and application thereof

A technology of carbon microspheres and hard carbon, applied in the field of hard carbon microspheres and its preparation, can solve the problems of complex preparation process, affecting the reversible capacity and cycle stability of hard carbon, and poor rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

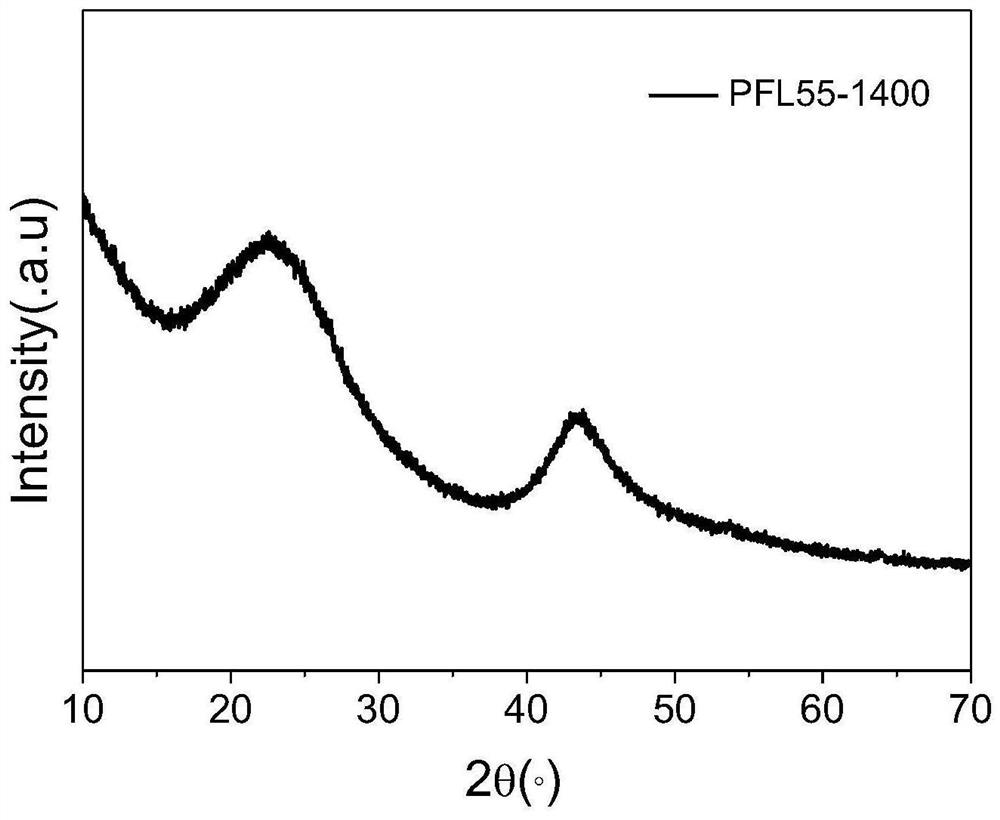

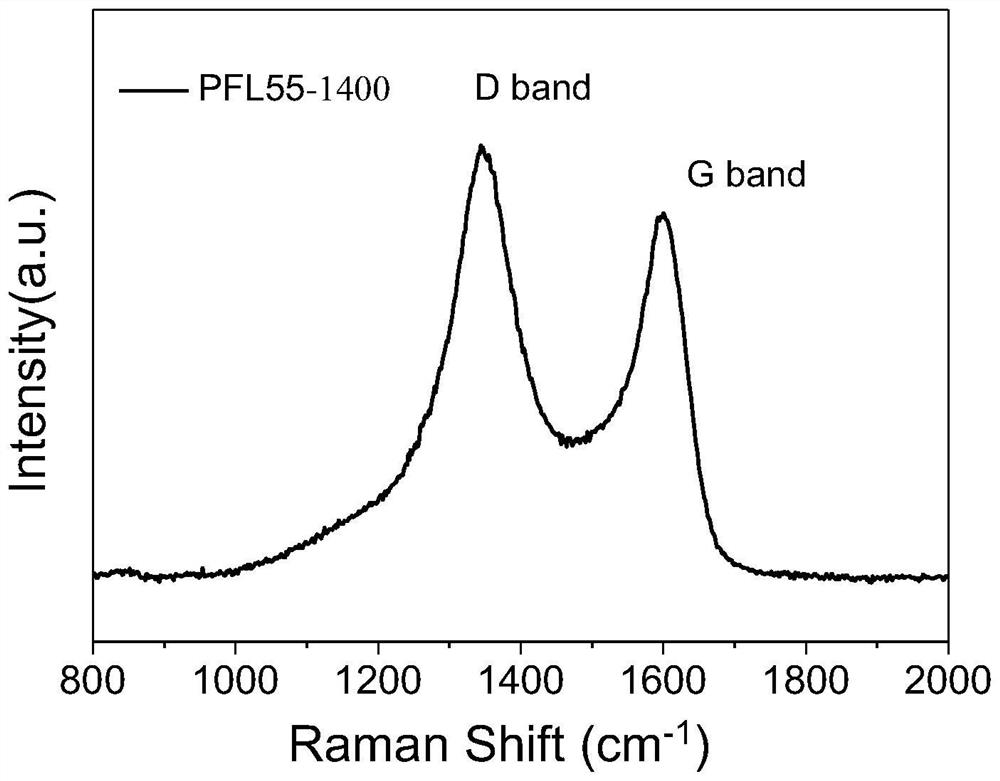

Embodiment 1

[0081] (1) Take 5g lignin, 10g mass fraction is 50% phenolic resin aqueous solution, be mixed with massfraction and be 15% aqueous solution (the total mass of lignin and phenolic resin accounts for 15% of aqueous solution gross mass), and at room temperature Stir for 1h;

[0082] (2) Transfer the aqueous solution of step (1) to the spray drying equipment, when the air inlet temperature is 150°C, the air outlet temperature is 90°C, and the ring air volume is 100mL min -1 , the inflow volume is 200ml h -1 Under the conditions of spray drying, the precursor nanospheres are obtained;

[0083] (3) Place the precursor nano-microspheres in an inert atmosphere, transfer them to an alumina crucible, place it in the center of a tube-type resistance furnace, and continuously pass in argon gas for protection. Then increase the temperature from room temperature to 1400 °C at a heating rate of 2 °C / min, and carbonize at a constant temperature of 1400 °C for 1 h, then naturally cool to room

Embodiment 2

[0086] (1) take by weighing 3g lignin, 14g mass fraction is 50% phenolic resin aqueous solution, is mixed with the mass fraction and is 15% aqueous solution (the total mass of lignin and phenolic resin accounts for 15% of aqueous solution gross mass), and at room temperature Stir for 3h;

[0087] (2) Transfer the aqueous solution of step (1) to the spray drying equipment, when the air inlet temperature is 140°C, the air outlet temperature is 90°C, and the ring air volume is 150mL min -1 , the inflow volume is 300ml h -1 Under the conditions of spray drying, the precursor nanospheres are obtained;

[0088] (3) Place the precursor nano-microspheres in an inert atmosphere, transfer them to an alumina crucible, place it in the center of a tube-type resistance furnace, and continuously pass in argon gas for protection. Then increase the temperature from room temperature to 1400 °C at a rate of 2 °C / min, and carbonize at a constant temperature of 1400 °C for 2 hours, then naturally

Embodiment 3

[0091] (1) take by weighing 7g lignin, 6g mass fraction is 50% phenolic resin aqueous solution, is mixed with the mass fraction and is 15% aqueous solution (the total mass of lignin and phenolic resin accounts for 15% of aqueous solution gross mass), and at room temperature Stir for 1h;

[0092] (2) Transfer the aqueous solution of step (1) to the spray drying equipment, when the air inlet temperature is 130°C, the air outlet temperature is 80°C, and the ring air volume is 200mL min -1 , the inflow volume is 250ml h -1 Under the conditions of spray drying, the precursor nanospheres are obtained;

[0093] (3) Place the precursor nano-microspheres in an inert atmosphere, transfer them to an alumina crucible, place it in the center of a tube-type resistance furnace, and continuously pass in argon gas for protection. Then increase the temperature from room temperature to 1400 °C at a rate of 2 °C / min, and carbonize at a constant temperature of 1400 °C for 3 hours, then naturally

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap