VOCs removal equipment for low-concentration VOCs waste gas treatment technology

A waste gas treatment and low-concentration technology, applied in membrane technology, gas treatment, air quality improvement, etc., can solve problems such as combustion and absorption that cannot be handled normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution in the present invention will be clearly and completely described below in conjunction with the accompanying drawings. The preferred embodiment in the description is only used as an example, and all other embodiments obtained by those skilled in the art without making creative work, All belong to the protection scope of the present invention.

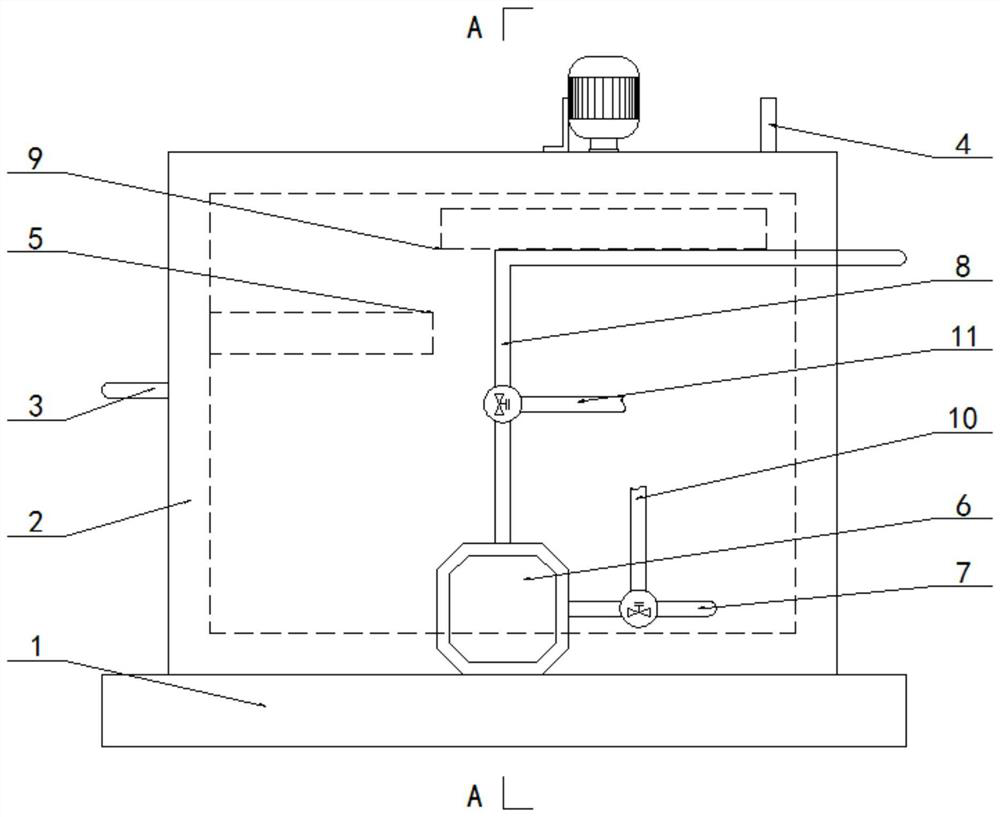

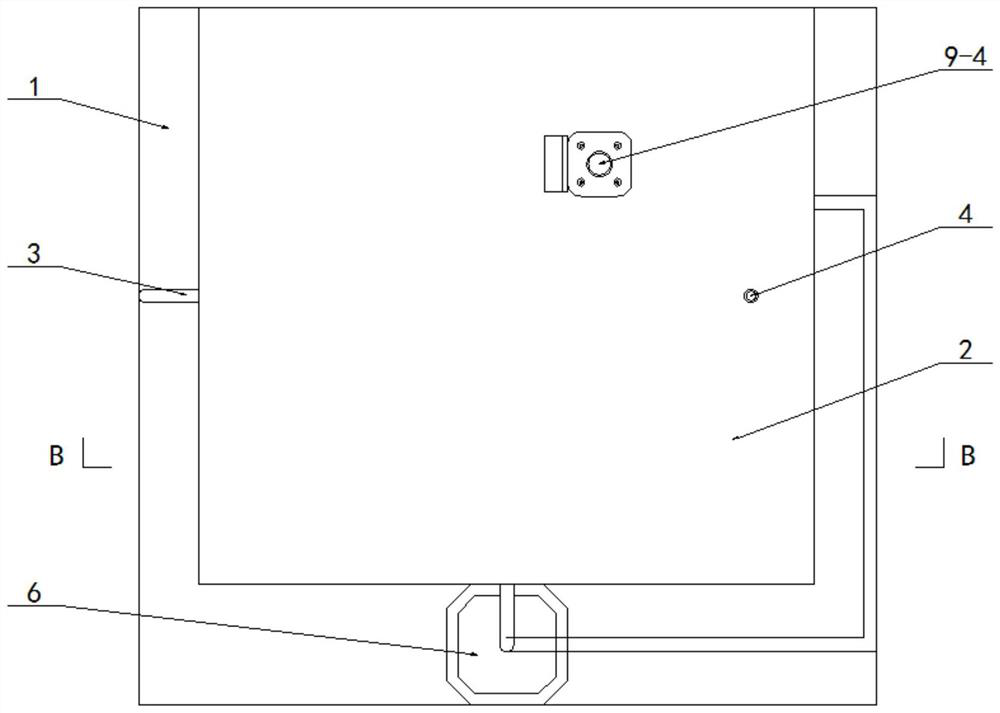

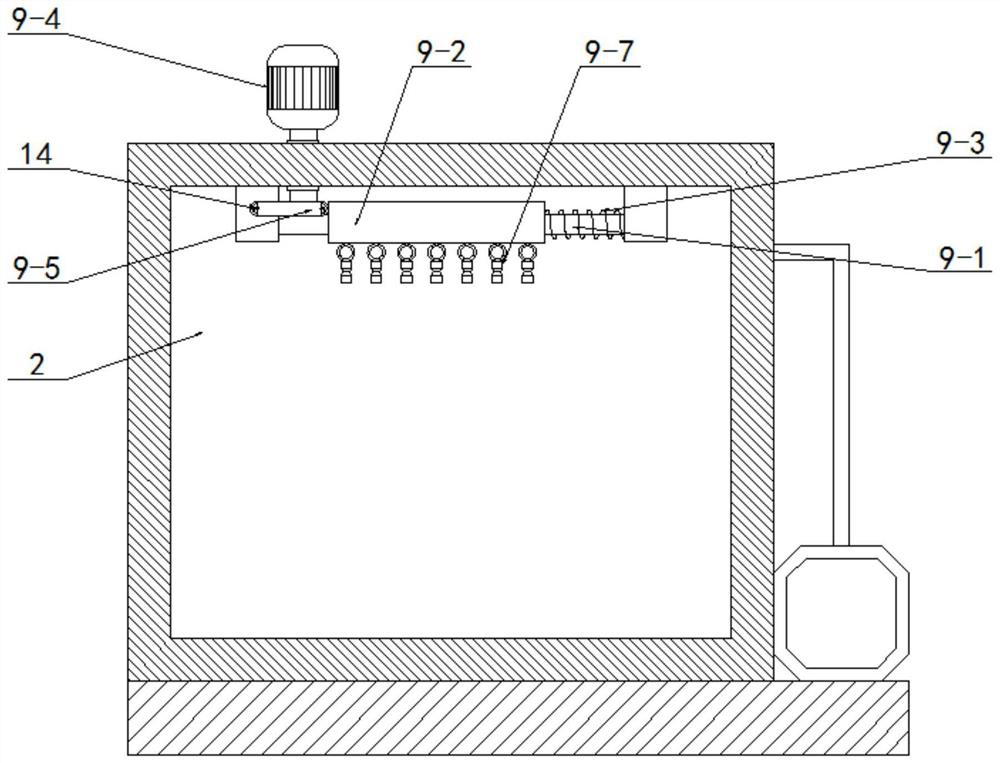

[0043] Such as Figure 1-Figure 5 As shown, this embodiment adopts the following technical solutions:

[0044] It includes a base 1 and a treatment box 2, wherein the treatment box 2 is riveted on the base 1, the left side wall of the treatment box 2 is pierced and fixed with an air inlet pipe 3, and the right side wall of the treatment box 2 is pierced and fixed with an air outlet pipe 4; it also contains:

[0045] Air injection part 5, said air injection part 5 is riveted on the lower inner side wall of processing box 2, and its inlet end is arranged in series with air intake pipe 3;

[0046] A pressurize

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap