Welding device for tower crane standard section

A welding device and standard section technology, applied in the field of pendant standard section welding devices, can solve the problems of affecting observation, being easily scalded, etc., and achieve the effects of facilitating welding conditions, increasing cleaning effect, and delicate cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

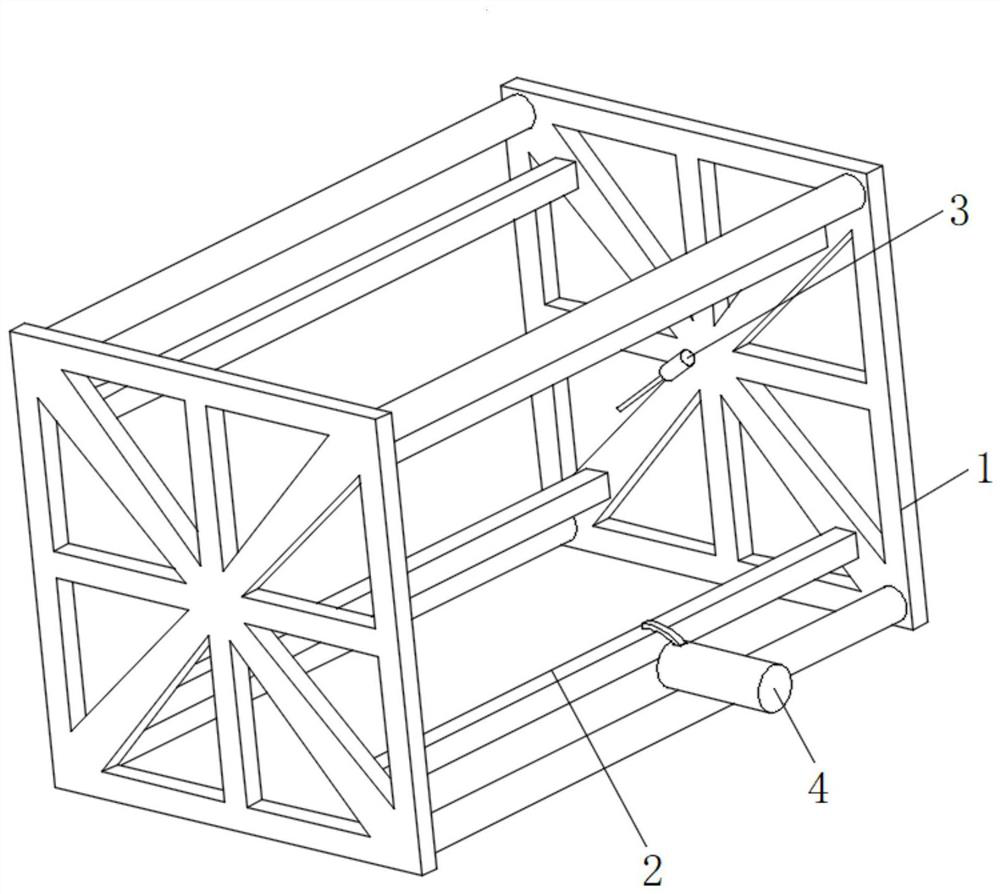

[0042] see Figure 1-4 , a welding device for a standard section of a pendant tower, comprising a welding frame 1, the inside of the welding frame 1 is clamped with a standard section body 2, and the outside of the standard section body 2 is provided with a welding torch 3;

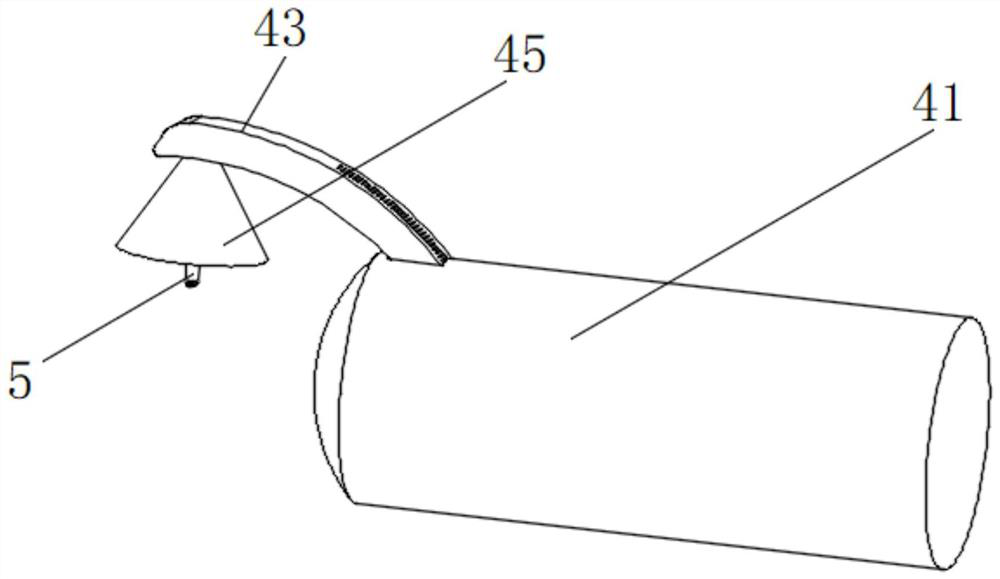

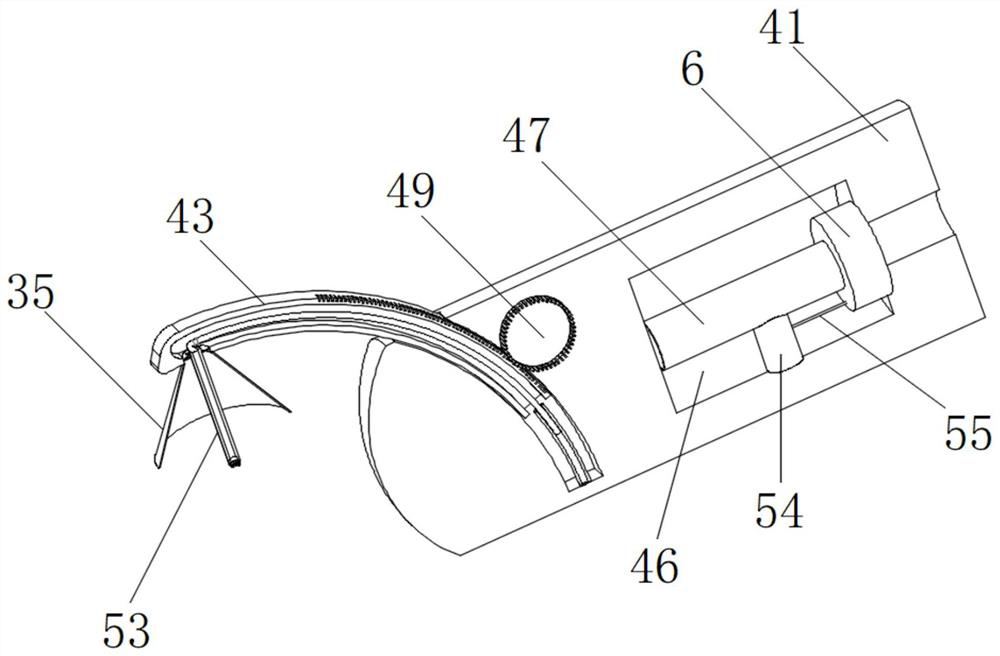

[0043] The outer side of the standard joint body 2 is provided with a cooling mechanism 4 to accelerate the cooling of solder joints and clean up welding slag. The cooling mechanism 4 includes a mounting arm 41, a chute 42 is provided on the top of the mounting arm 41, and an inner cavity 46 is provided inside the mounting arm 41;

[0044] Both the welding torch 3 and the cooling mechanism 4 are controlled by a mechanical arm;

[0045] The inside of the chute 42 is provided with a cleaning mechanism 5 for cleaning the oxide layer on the surface of the solder joint;

[0046] The inner cavity 46 is equipped with a circulating mechanism 6 which is continuously working by the auxiliary cleaning mechanism 5, and

Embodiment 2

[0057] see Figure 1-5 , a welding device for a standard section of a pendant tower, comprising a welding frame 1, the inside of the welding frame 1 is clamped with a standard section body 2, and the outside of the standard section body 2 is provided with a welding torch 3;

[0058] The outer side of the standard joint body 2 is provided with a cooling mechanism 4 to accelerate the cooling of solder joints and clean up welding slag. The cooling mechanism 4 includes a mounting arm 41, a chute 42 is provided on the top of the mounting arm 41, and an inner cavity 46 is provided inside the mounting arm 41;

[0059] Both the welding torch 3 and the cooling mechanism 4 are controlled by a mechanical arm;

[0060] The inside of the chute 42 is provided with a cleaning mechanism 5 for cleaning the oxide layer on the surface of the solder joint;

[0061] The inner cavity 46 is equipped with a circulating mechanism 6 which is continuously working by the auxiliary cleaning mechanism 5, and

Embodiment 3

[0076] see Figure 1-7 , a welding device for a standard section of a pendant tower, comprising a welding frame 1, the inside of the welding frame 1 is clamped with a standard section body 2, and the outside of the standard section body 2 is provided with a welding torch 3;

[0077] The outer side of the standard joint body 2 is provided with a cooling mechanism 4 to accelerate the cooling of solder joints and clean up welding slag. The cooling mechanism 4 includes a mounting arm 41, a chute 42 is provided on the top of the mounting arm 41, and an inner cavity 46 is provided inside the mounting arm 41;

[0078] Both the welding torch 3 and the cooling mechanism 4 are controlled by a mechanical arm;

[0079] The inside of the chute 42 is provided with a cleaning mechanism 5 for cleaning the oxide layer on the surface of the solder joint;

[0080] The inner cavity 46 is equipped with a circulating mechanism 6 which is continuously working by the auxiliary cleaning mechanism 5, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap