PVC mother liquor recycling treatment device and process

A treatment device and mother liquor technology, which is applied in the field of PVC mother liquor reuse treatment device, can solve the problems of low filter backwash efficiency, high ozone utilization rate, and small footprint, so as to reduce the water intake of the factory and reduce the difficulty of treatment , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

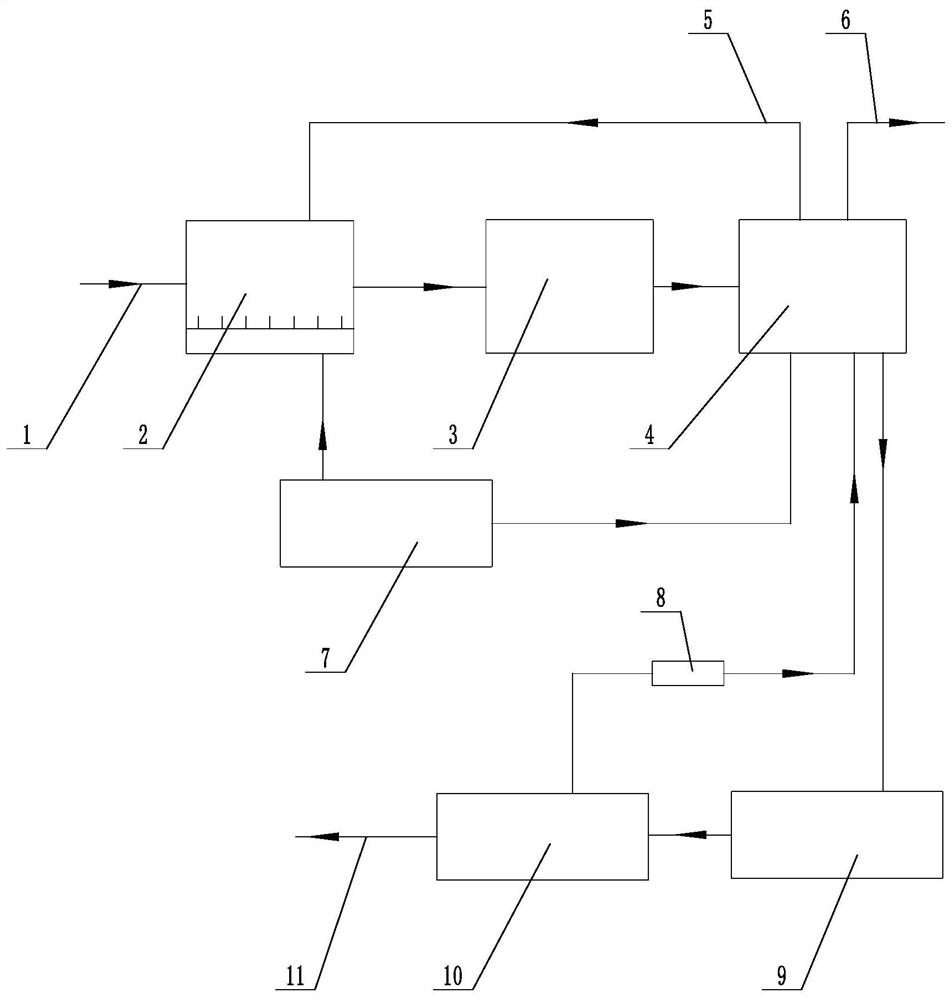

Image

Examples

Embodiment 1

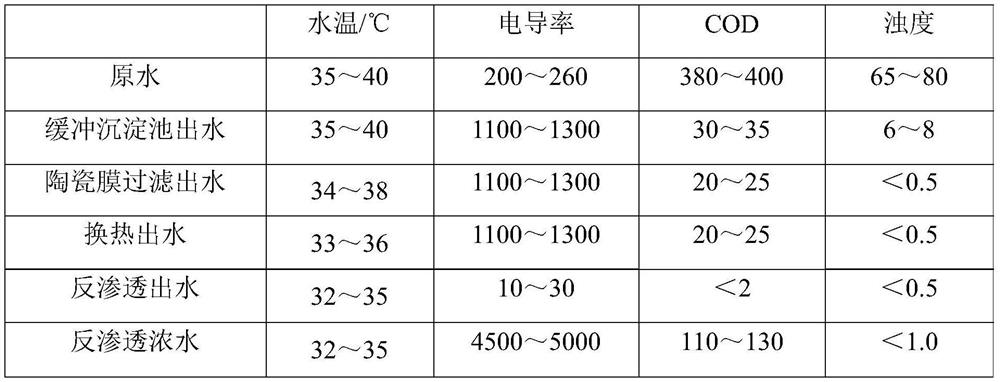

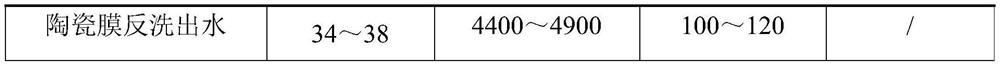

[0054] A PVC mother liquor, temperature 60-70℃, COD 380-400mg / L, turbidity 65-80NTU, first enters the advanced oxidation reactor, adjusts the pH value to 3.0, and the concentration of hydrogen peroxide is 2.0 times that of sewage COD, sulfuric acid The mass ratio of ferrous iron to hydrogen peroxide is preferably 1:1, and the oxidation reaction time is 2.0 h. The ozone concentration directly supplied by the ozone generator to the advanced oxidation reactor is 20mg / L, and the buffer sedimentation tank adopts a slanted plate sedimentation tank, the pH value of the precipitation is 7.0-8.5, and the precipitation time is 1.0h. The ceramic filter adopts tubular membrane, cross-flow filtration, and the filtration accuracy is 100nm. 80%. The ceramic membrane ozone backwashing concentration is 100mg / L, the pressure is 0.6MPa, the air washing time is 120s, and the combined water and air washing time is 240s. Table 1 for the effluent water quality of each unit.

[0055] Table 1 em

Embodiment 2

[0059] A PVC mother liquor, temperature 50-55℃, COD 100-130mg / L, turbidity 38-66NTU, first enters the advanced oxidation reactor, adjusts the pH value to 4.0, and the concentration of hydrogen peroxide is 1.5 times that of sewage COD, sulfuric acid The mass ratio of ferrous iron to hydrogen peroxide is preferably 1:5, and the oxidation reaction time is 0.5h. The ozone concentration directly supplied by the ozone generator to the advanced oxidation reactor is 0 mg / L, and the buffer sedimentation tank adopts a slanted plate sedimentation tank, the pH value of the sedimentation is 7.0-8.5, and the sedimentation time is 2.0h. The ceramic filter adopts tubular membrane, cross-flow filtration, the filtration accuracy is 50nm, the outlet water temperature of the heat exchanger is less than 40°C, the dosing concentration of sodium bisulfite is 20mg / L, the operating pressure of the reverse osmosis device is 1.5MPa, and the water production rate 85%. The ceramic membrane ozone backw

Embodiment 3

[0064] A PVC mother liquor, temperature 75-80℃, COD 180-200mg / L, turbidity 20-30NTU, first enters the advanced oxidation reactor, adjusts the pH value to 3.5, and the concentration of hydrogen peroxide is 1.8 times that of sewage COD, sulfuric acid The mass ratio of ferrous iron to hydrogen peroxide is preferably 1:10, and the oxidation reaction time is 1.0 h. The ozone concentration directly supplied by the ozone generator to the advanced oxidation reactor is 15 mg / L, and the buffer sedimentation tank adopts a slanted plate sedimentation tank, the pH value of the sedimentation is 7.0-8.5, and the sedimentation time is 3.0 hours. The ceramic filter adopts tubular membrane, cross-flow filtration, the filtration accuracy is 5nm, the outlet water temperature of the heat exchanger is less than 40°C, the dosing concentration of sodium bisulfite is 10mg / L, the operating pressure of the reverse osmosis device is 1.0MPa, and the water production rate 80%. The ceramic membrane ozon

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap