Inner hole cladding laser head

A laser head and cladding technology, applied in metal material coating process, coating and other directions, can solve the problems of uneven energy distribution of circular spot, uneven repair, etc., to improve repair effect, improve service life, and uniform energy distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

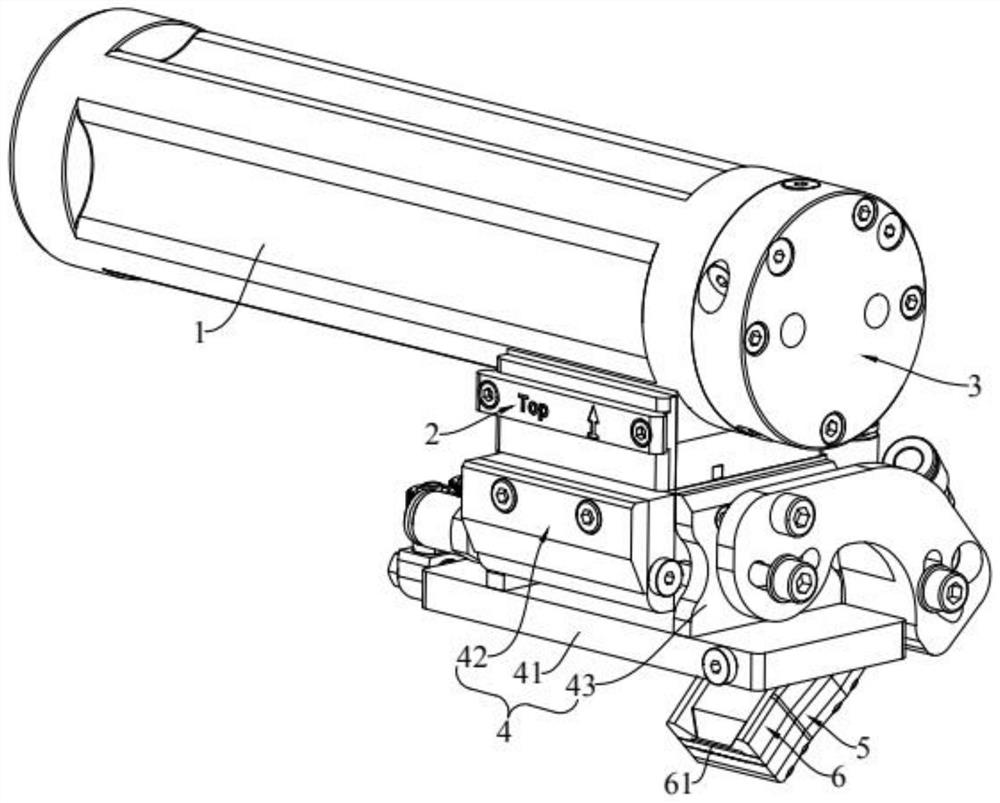

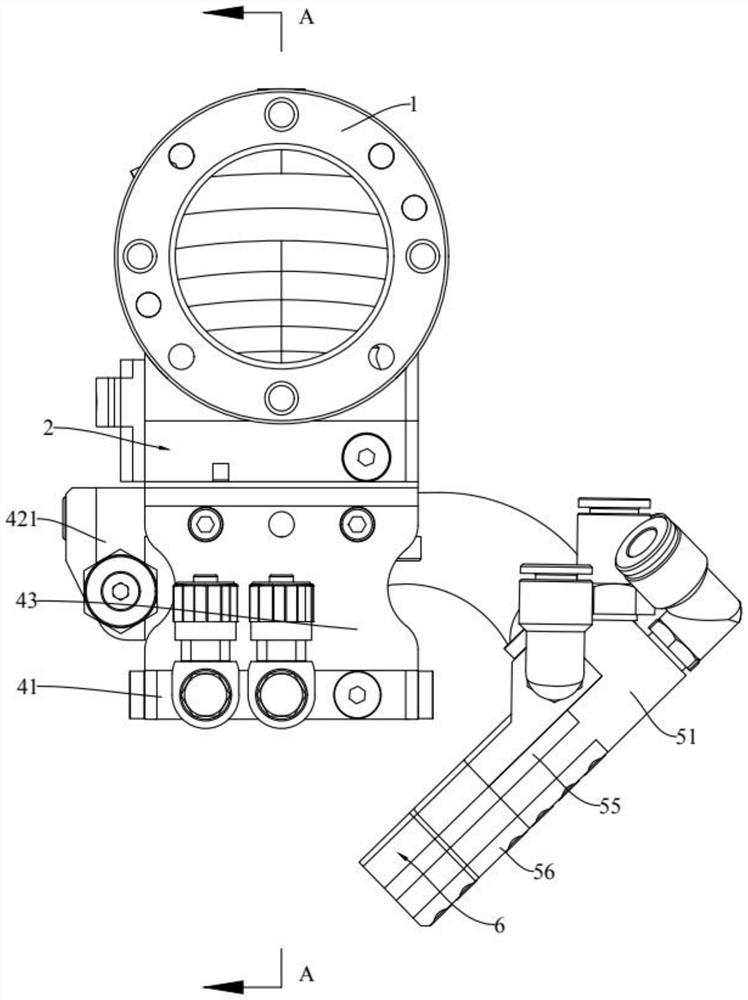

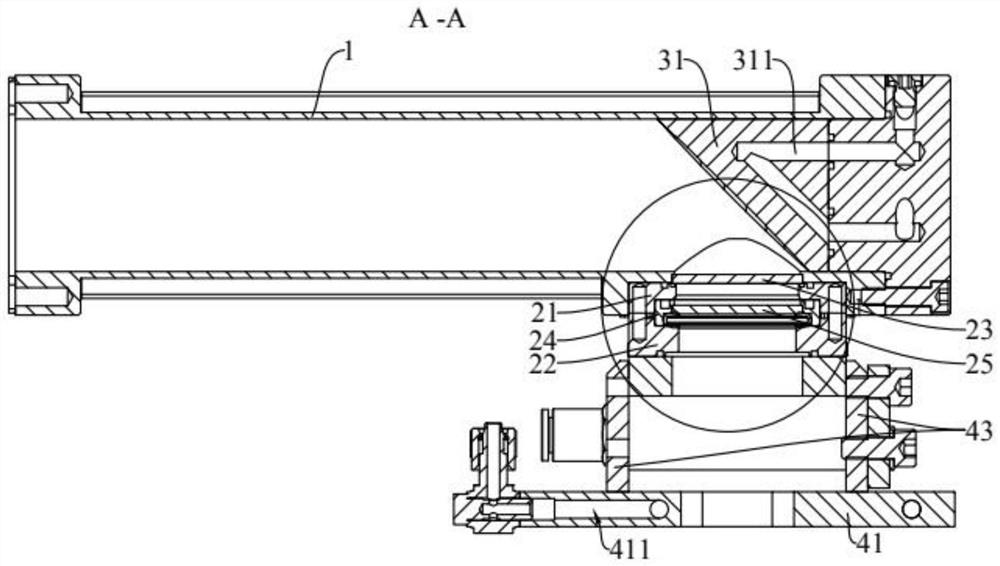

[0048] This embodiment provides a laser head for inner hole cladding, such as Figure 1 to Figure 4 As shown, the inner hole cladding laser head includes a light pipe 1, a protective mirror assembly 2, a reflector assembly 3 arranged at one end of the light pipe 1, a first protection assembly 4, a powder feeding nozzle assembly 5 and a second protection assembly 6 . The protective mirror assembly 2 is arranged on one side of the light pipe 1 at a position corresponding to the mirror assembly 3 , and the reflective mirror assembly 3 can reflect the laser beam in the light pipe 1 to the protective mirror assembly 2 . The mirror assembly 3 can reflect the laser beam into a striped light spot. The first protective assembly 4 is disposed below the protective mirror assembly 2 . The powder feeding nozzle assembly 5 is arranged on one side of the protective mirror assembly 2, and the discharge port of the powder feeding nozzle assembly 5 faces below the first protective assembly 4, an

Embodiment 2

[0059] This embodiment provides a laser head for inner hole cladding. The working principle of this embodiment is the same as that of Embodiment 1, and the similarities will not be repeated here. The difference lies in:

[0060] like Figure 7 As shown, the first guard assembly 4 includes a guard plate 41 and an air knife structure 42 . The protective plate 41 is disposed under the protective mirror assembly 2 through the connecting seat 44 , and the laser beam can pass through the connecting seat 44 and the protective plate 41 in sequence. The air knife structure 42 is arranged under the protective plate 41 , and the air knife structure 42 can blow out an air flow perpendicular to the laser beam emitting direction. In detail, the air knife structure 42 includes an air knife seat 421. There is a cavity in the air knife seat 421. A second air outlet is opened on one side of the air knife seat 421. Gas is introduced into the cavity, and the gas is sprayed from the second air outle

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap