Chain plate type aluminum bar heating furnace with intelligent feeding device

A chain plate type heating furnace technology, applied in the field of aluminum rod heating furnace, can solve the problems of vulnerable personnel, aluminum rod slipping, uneven heating of aluminum rods, etc., to avoid random movement, improve processing efficiency, and achieve good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

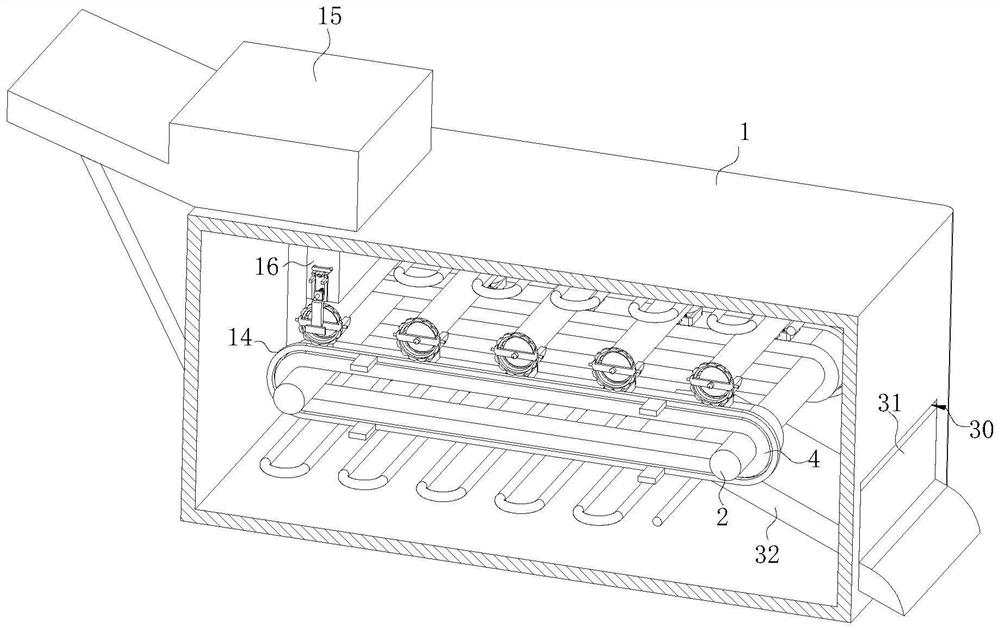

[0027] see Figure 1-9 , the present invention provides a technical solution: a chain plate aluminum rod heating furnace with an intelligent feeding device, including a heating box 1, two first rotating shafts 2 are rotatably connected to the inside of the heating box 1, and one of the first rotating shafts 2 is outside The drive motor 3 is fixedly connected to the end, and the drive motor 3 is fixedly connected to the outer wall of the heating box 1, and the outer surfaces of the two first rotating shafts 2 are jointly driven and connected with two conveyor chains 4, and the outer surfaces of the two conveyor chains 4 are There are several sets of receiving mechanisms for receiving aluminum rods connected, and the receiving devices are distributed along the edge array of the conveyor chain 4. The top of the heating box 1 is connected with a feeding mechanism that automatically adds aluminum rods into the heating box 1 one by one. When the receiving mechanism moves to its bottom,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap