Formation method of semiconductor structure

A semiconductor and graphics technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of increasing the difficulty and complexity of integrated circuits, achieve good graphics effects, improve matching, and improve graphics accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It can be seen from the background art that how to improve the matching degree between the target pattern and the design pattern formed on the wafer has become a challenge.

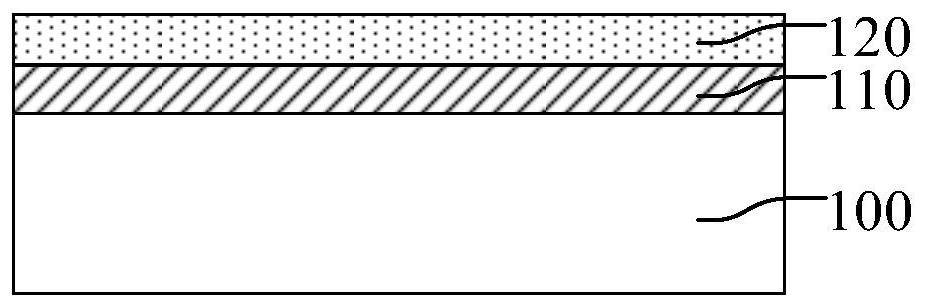

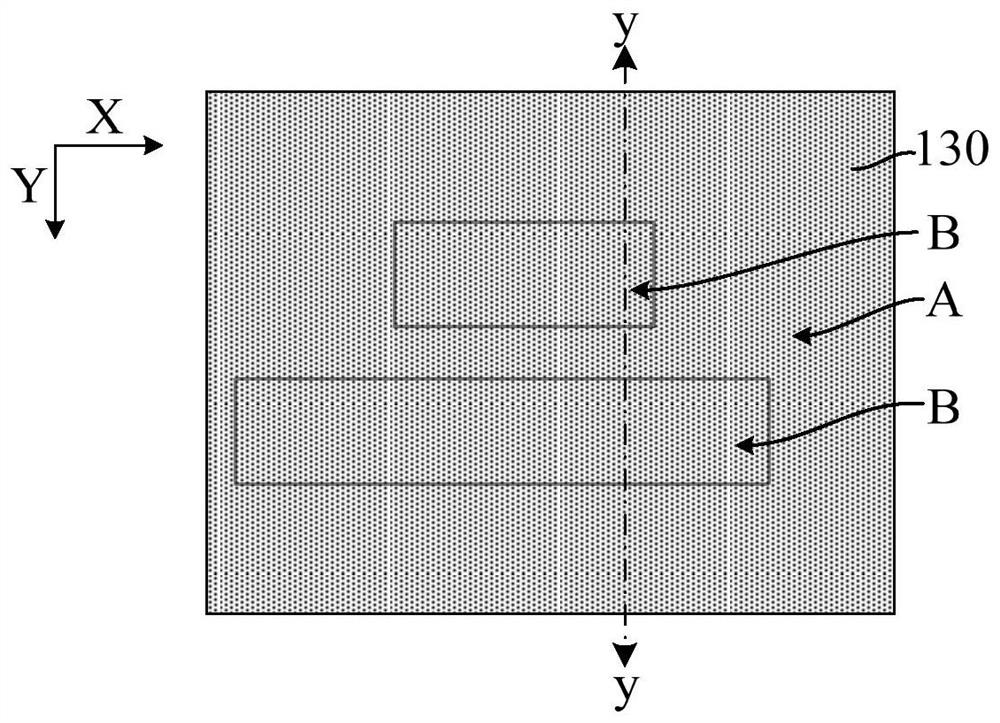

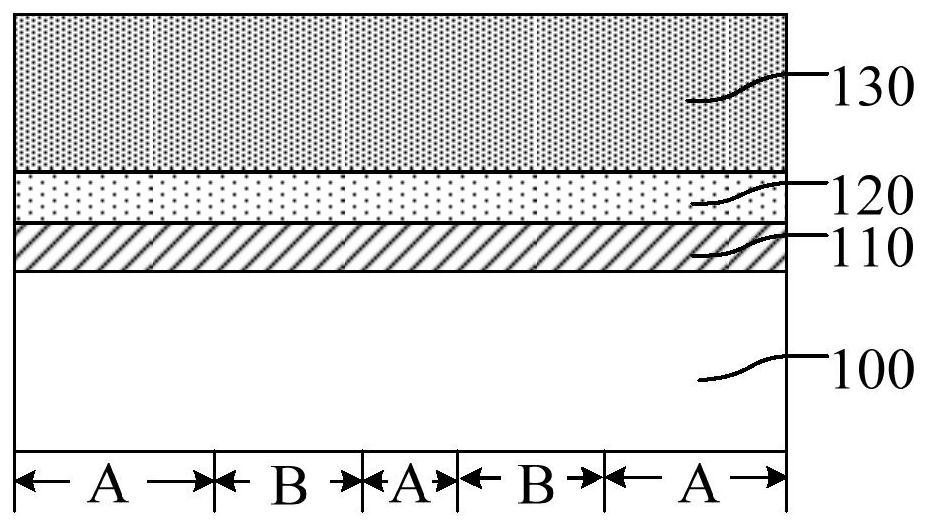

[0024] In order to solve the technical problem, an embodiment of the present invention provides a method for forming a semiconductor structure, including: providing a substrate, including a target layer for forming a target pattern; forming a core layer on the substrate, and the core layer includes The anti-etch area for forming the anti-etch layer and the sacrificial area for forming the sacrificial layer; ion doping is carried out to the core layer of the sacrificial area, which is suitable for making the core layer of the sacrificial area and the anti-etch area The etched rate of the core layer is different, the core layer doped with ions in the sacrificial region is used as a sacrificial layer, and the core layer not doped with ions in the anti-etching region is used as an anti-etching layer; Form

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap