Device and method for treating thallium-containing wastewater in non-ferrous metal metallurgy

A technology for non-ferrous metals and waste water, applied in metallurgical waste water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem that the thallium element cannot meet the discharge limit requirements, achieve good economic benefits and reduce environmental risks , the effect of avoiding the harm to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

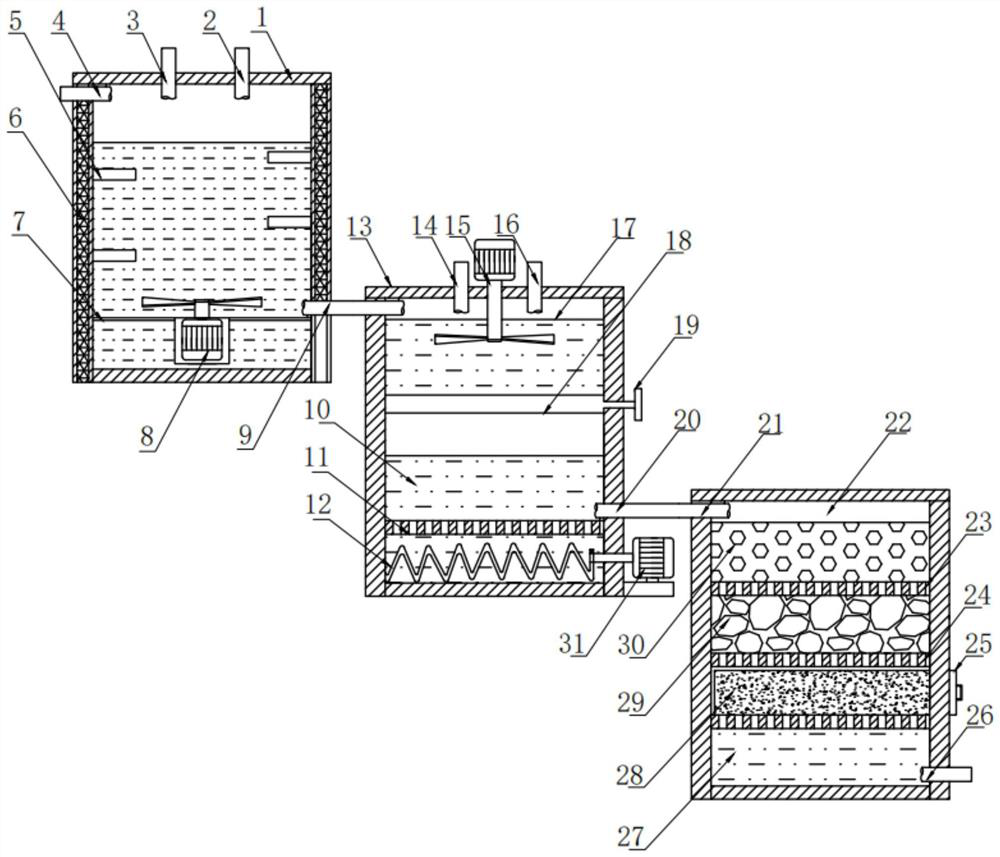

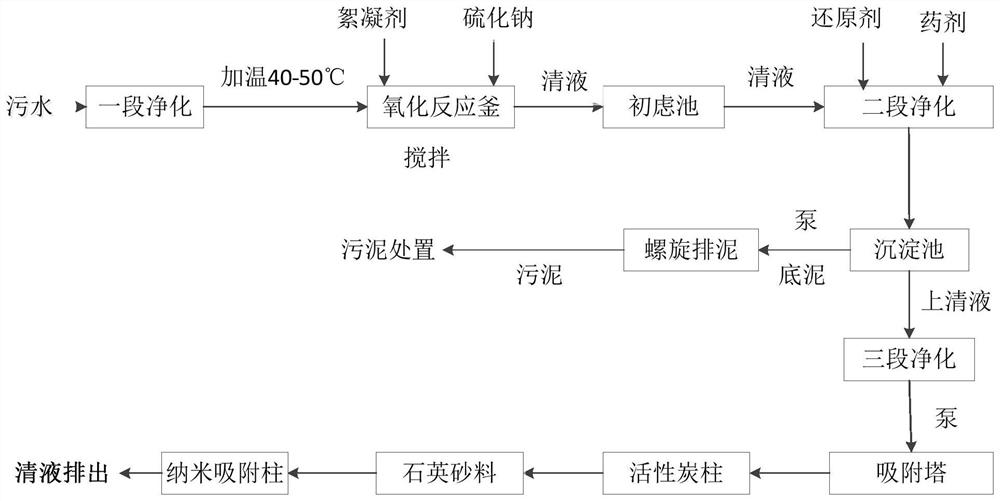

[0029] like figure 1 As shown in the figure, a device for treating thallium-containing wastewater in non-ferrous metal smelting according to the present invention includes a first-stage liquid cleaning device 1, a second-stage liquid cleaning device 13 and a third-stage liquid cleaning device 22. The top is respectively provided with a sodium sulfide inlet 2 and a flocculant inlet 3 for adding sodium sulfide and flocculant, a sewage inlet 4 is provided on the top side of the upper top of the first section of the liquid cleaning device 1, and on the inner cavity wall of the first section of the liquid cleaning device 1 An anti-rotation baffle 5 is provided. Since the water flow is required to generate intense turbulence during the mixing process, the medicine and water can be fully mixed in a relatively fast time. Therefore, the anti-rotation baffle 5 is irregularly arranged in the interior of the first stage of the liquid purification device 1. On the cavity wall, the irregular a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap