Demisting device in natural gasification station

A defogging device and natural gas technology, applied in chemical instruments and methods, gas/liquid distribution and storage, separation methods, etc., can solve the problem that the extraction method cannot be fundamentally eliminated, the air in the storage and distribution station is not easy to circulate, and the station personnel Potential safety hazards and other issues, to achieve the effect of improving the heating effect, reducing the cost of defogging, and eliminating the problem of fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

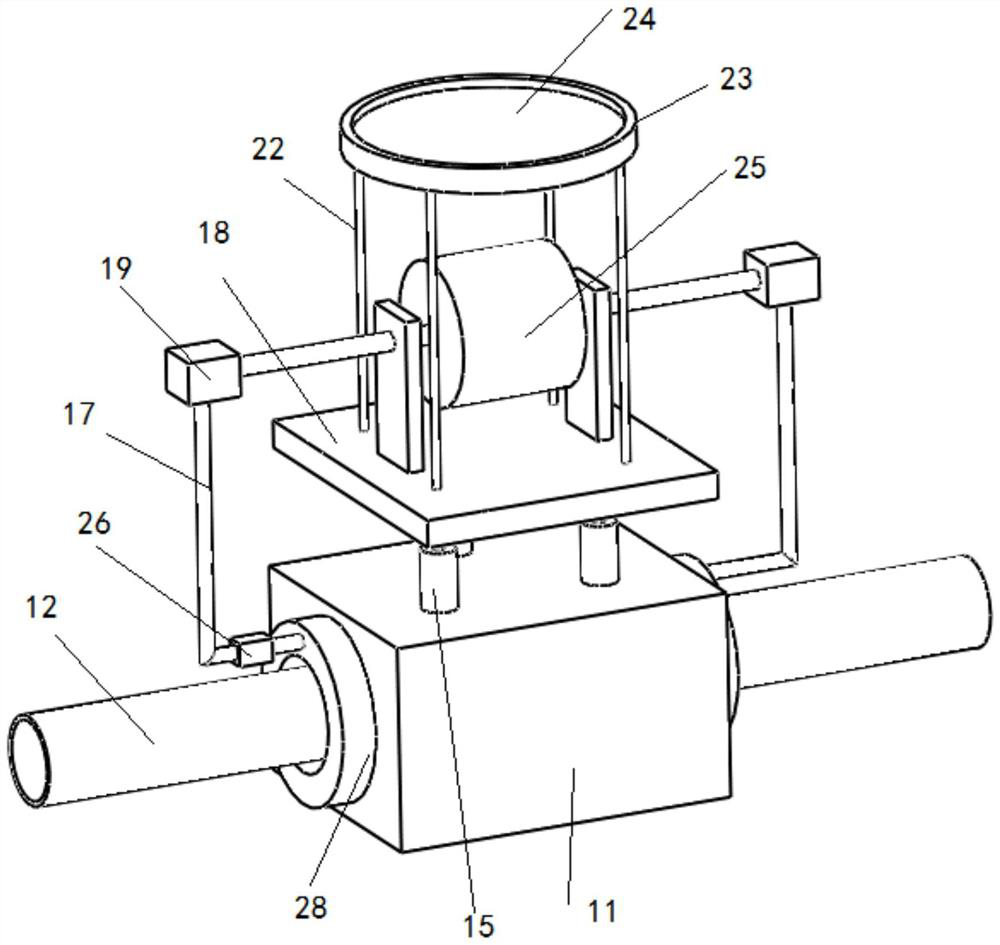

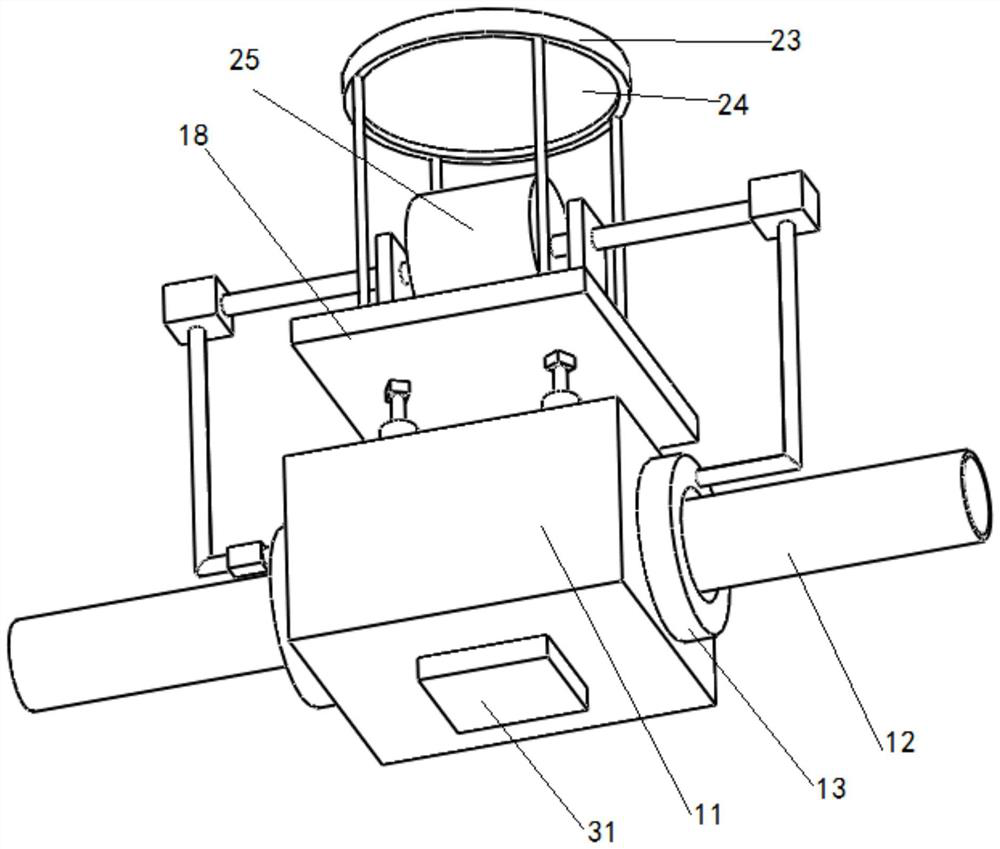

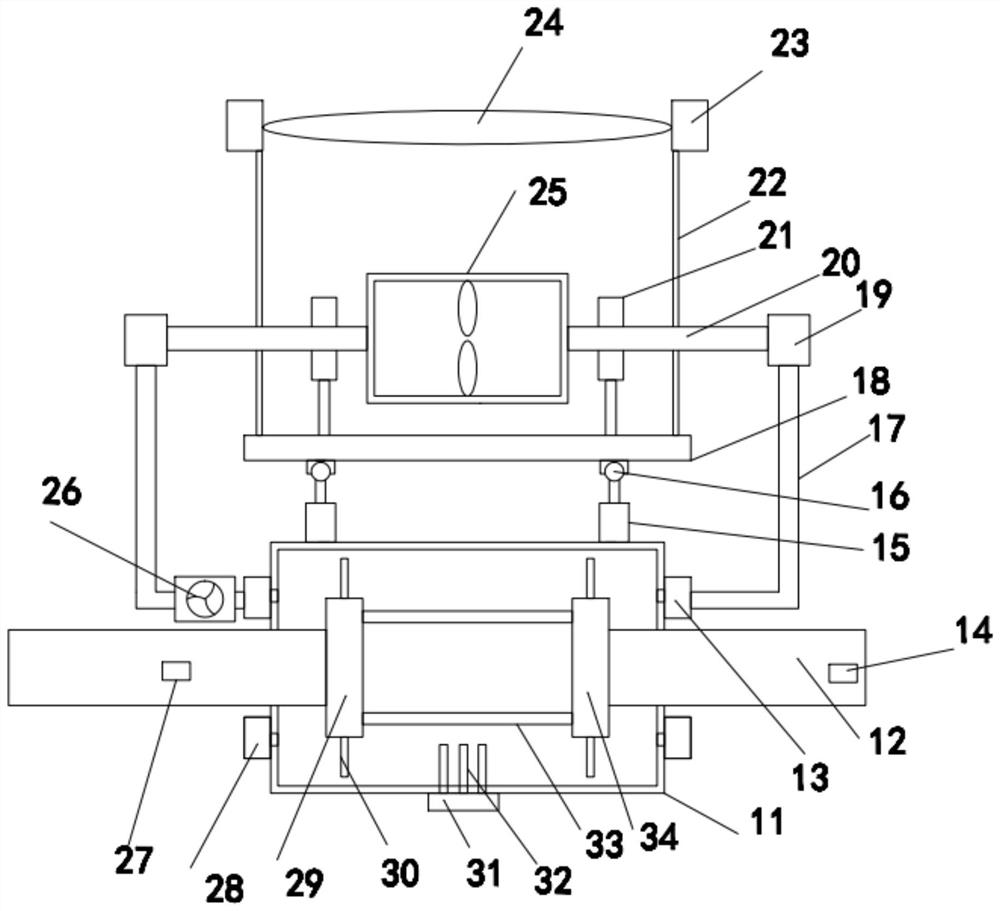

[0023] see Figure 1-Figure 4 , In the embodiment of the present invention, a demisting device in a natural gas chemical station includes a natural gas transmission cylinder 12 for transmitting low-temperature natural gas, and a heating box 11 for providing heat is provided on the outside of the natural gas transmission cylinder 12. The heating box The natural gas transmission cylinder 12 inside 11 is provided with a heat exchange element for increasing the heat exchange area, a mounting seat plate 18 is provided above the heating box 11, and a mounting seat plate 18 is provided above the mounting seat plate 18 for connecting with the heating box. 11. A solar heating assembly for heat exchange, the solar heating assembly communicates with the outside of the heating box 11 through a liquid guide hose 17, and the liquid guide hose 17 is provided with a circulating pump 26 for promoting fluid circulation. The solar heating assembly provides heat energy for the heating box 11, thereb

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap