Flushing device for preventing mud cake formation of large-diameter slurry balance shield

A mud-water balance and flushing device technology, which is applied to mining equipment, tunnels, earthwork drilling, etc., can solve the problems of affecting the flushing efficiency, limited flushing angle, and easy blockage, and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

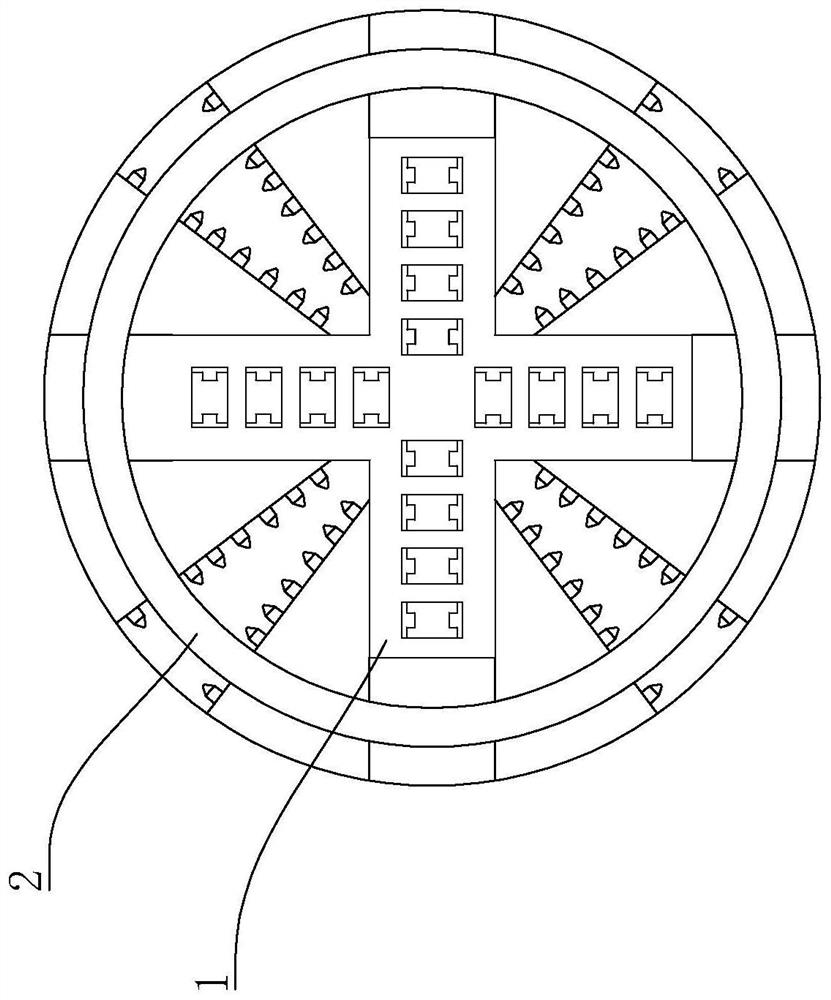

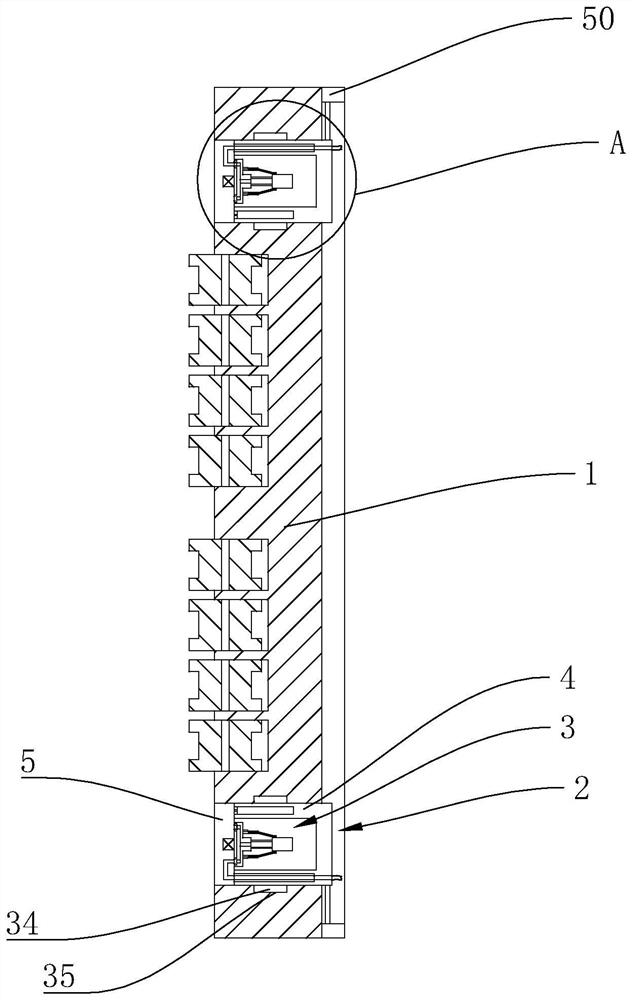

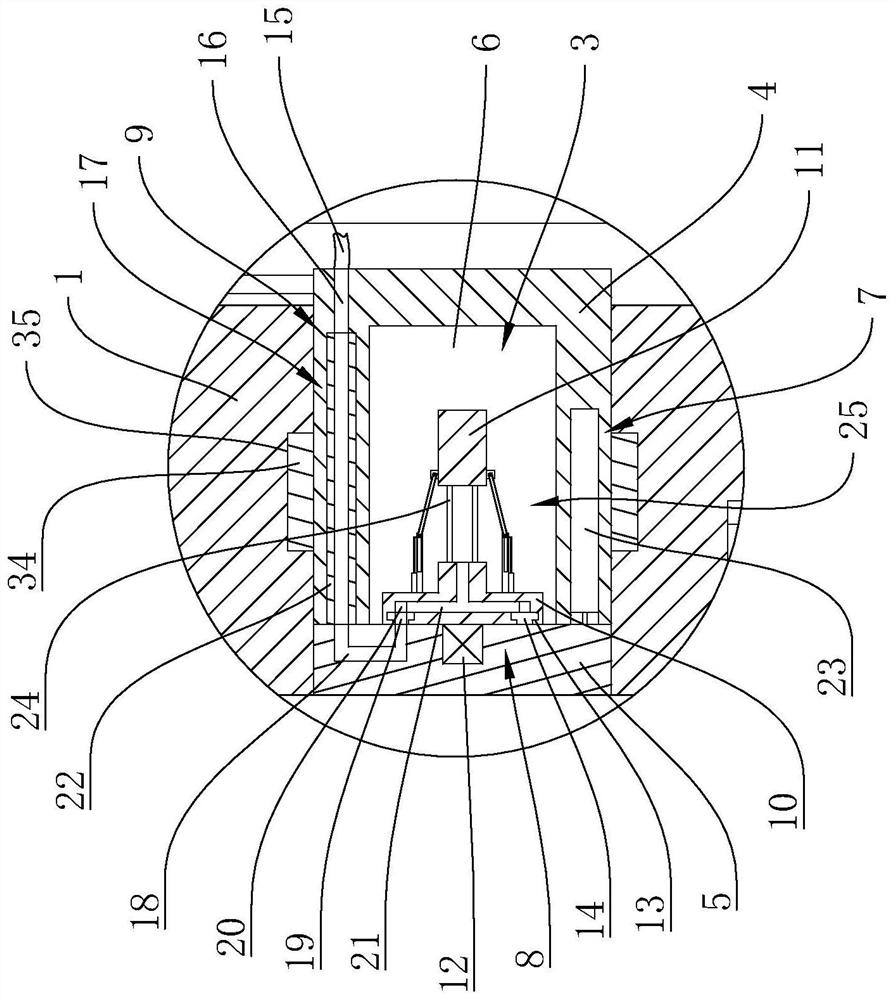

[0030] like Figure 1-Figure 4 As shown in the figure, a large-diameter mud-water balance shield structure prevents mud cake washing, including a cutter head 1, and the cutter head 1 is provided with a nozzle outer casing 2 along the axial direction, and the sprinkler head outer casing 2 is annular It is rotatably connected with the cutter head 1 , and the spray head housing 2 is provided with a flushing mechanism 3 for washing the cutters on the cutter head 1 and the outer surface of the cutter head 1 .

[0031] The cutter head 1 is installed on the front shield 50, and the inner end of the outer casing of the spray head is fixedly connected with the front shield. When the cutter head rotates, the outer casing of the spray head remains stationary.

[0032] In this embodiment, the flushing mechanism 3 disposed on the outer casing 2 of the spray head can flush the cutter head and the cutters on the cutter head at multiple angles, so that the mud cakes on the cutter head can be qui

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap