Method for preparing cinnamene copolymerization homogeneous resin and its preparing method

A technology made of styrene and resin, applied in the field of styrene copolymerization homogeneous resin preparation, can solve the problems of poor strength, low exchange capacity and short service life of ion exchange resin, and achieve the advantages of reducing consumption, improving product efficiency and improving service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

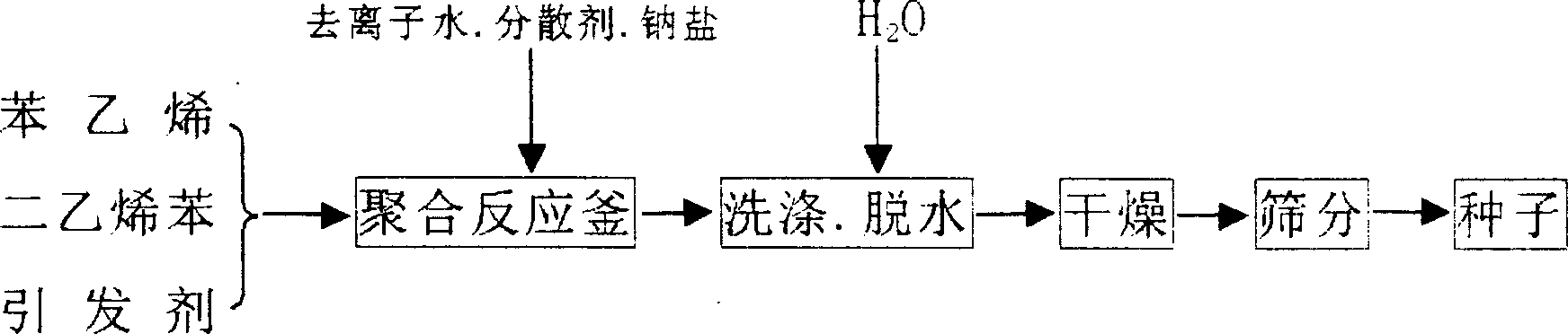

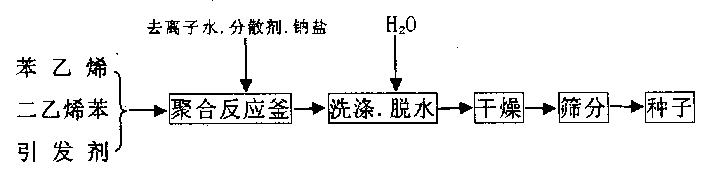

[0010] Embodiment 1: with reference to attached figure 1 . The "seed" component (parts by weight) used for the preparation of styrene copolymerized homogeneous resin: at least 100 styrene, 0.1 divinylbenzene, 0.35 initiator, 110 deionized water, 0.8 dispersant, and 0.10 sodium salt. Add deionized water, dispersant, and sodium salt into the polymerization reactor and stir, and then put the initiator, divinylbenzene, and styrene into the reactor and stir evenly. After the closed reactor is ventilated with nitrogen to remove the air in the reactor, the temperature is raised to react. The reaction temperature is controlled within the range of 60-110°C (best 80-90°C), and the reaction time is 18-25 hours (best 20-22 hours). Sift the seeds.

Embodiment 2

[0011] Embodiment 2: with reference to attached figure 1 . The "seed" component (parts by weight) used for the preparation of styrene copolymerized homogeneous resin: at least 100 styrene, 0.35 divinylbenzene, 0.10 initiator, 250 deionized water, 0.3 dispersant, and 0.30 sodium salt. Add deionized water, dispersant, and sodium salt into the polymerization reactor, stir at the same time, then put the initiator, divinylbenzene, and styrene into the reactor and stir evenly, and then seal the reactor with nitrogen to remove the air in the reactor, then heat up Reaction, the reaction temperature is controlled within the range of 60-110°C (best 80-90°C), the reaction time is 18-25 hours (best 20-22 hours), and after the reaction is completed, the material is cooled below 40°C and discharged, washed with water, Dry and sieve the seeds.

Embodiment 3

[0012] Embodiment 3: with reference to attached figure 1 . The "seed" component (parts by weight) used for the preparation of styrene copolymerized homogeneous resin: at least 100 styrene, 0.225 divinylbenzene, 0.225 initiator, 180 deionized water, 0.55 dispersant, and 0.20 sodium salt. Add deionized water, dispersant, and sodium salt into the polymerization reactor, stir at the same time, then put the initiator, divinylbenzene, and styrene into the reactor and stir evenly, and then seal the reactor with nitrogen to remove the air in the reactor, then heat up Reaction, the reaction temperature is controlled within the range of 60-110°C (best 80-90°C), the reaction time is 18-25 hours (best 20-22 hours), and after the reaction is completed, the material is cooled below 40°C and discharged, washed with water, Dry and sieve the seeds.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap