Wheel carrier for a two-track motor vehicle

a two-track motor vehicle and wheel carrier technology, applied in suspensions, vehicle springs, resilient suspensions, etc., can solve the problem of limiting the rotary adjustment of the angle stop, and achieve the effect of avoiding the limitation of the angle stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

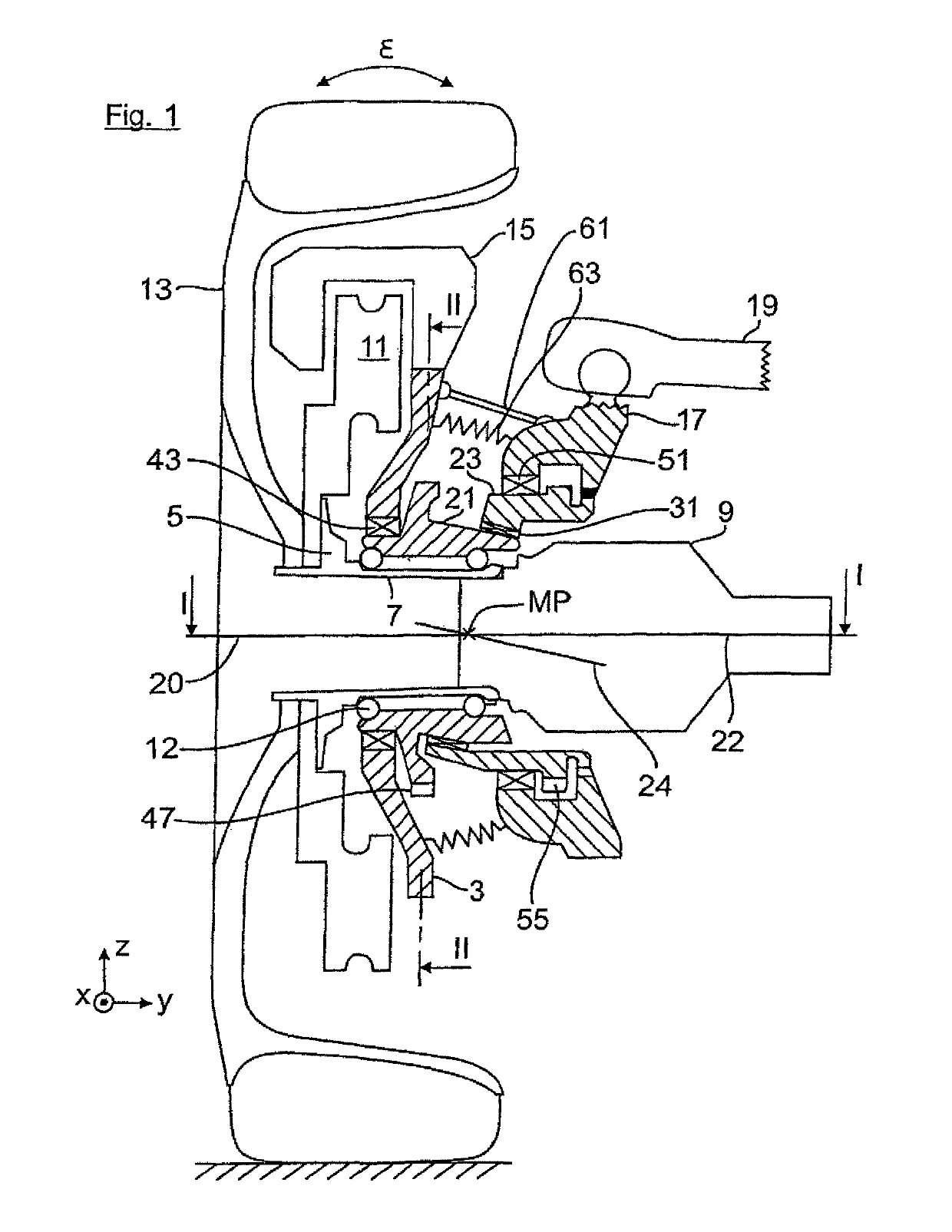

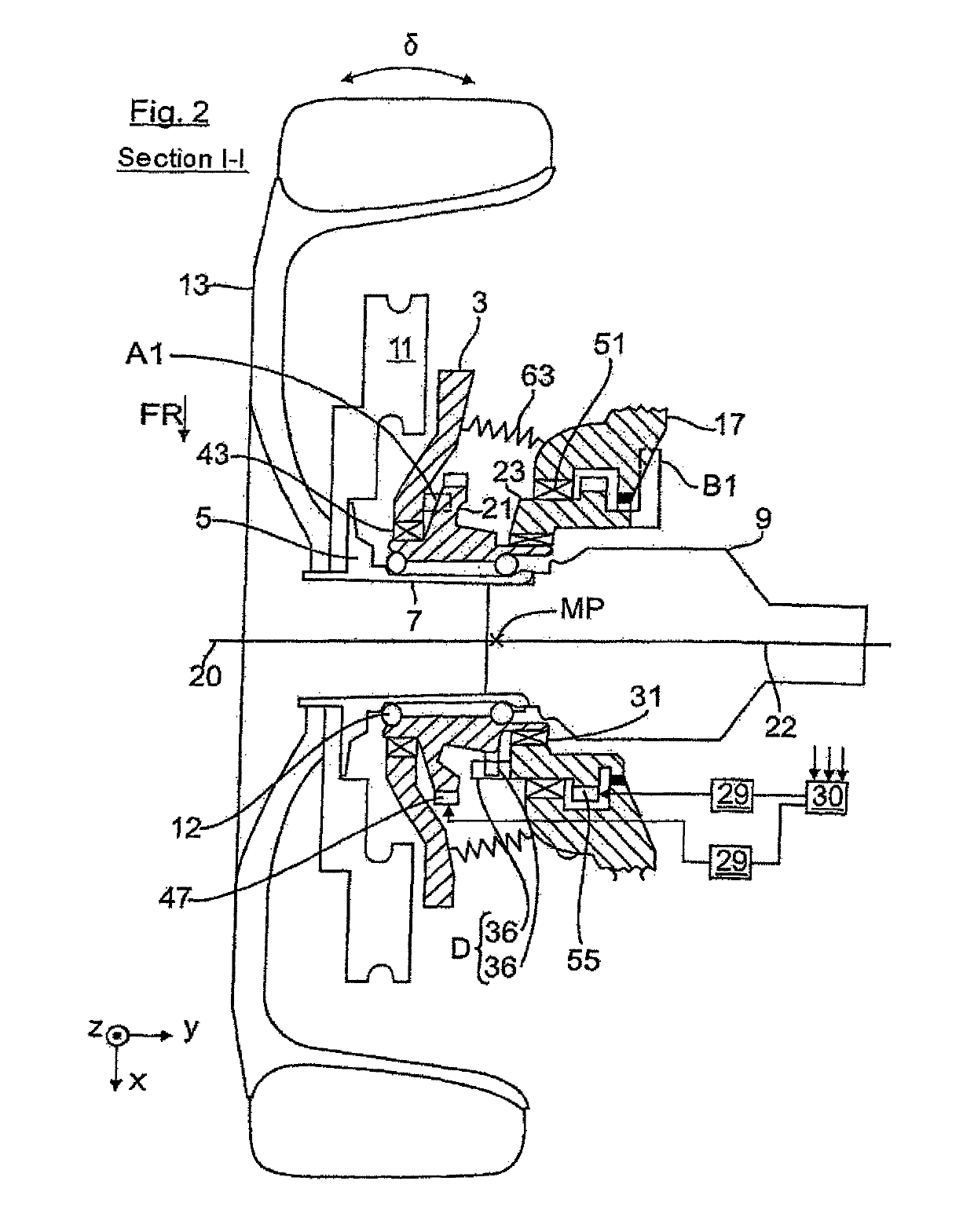

[0030]FIG. 1 shows the wheel carrier with mounted vehicle wheel 13 in a side view. The wheel carrier has a carrier part 3 in which a wheel flange 5 is rotatably supported with its hub section 7 in a wheel bearing 12 with interposition of a bearing 43. On the wheel flange 5 a brake disc 11 and a vehicle wheel 13, via its wheel rim, are mounted. The brake disc 11 together with a brake caliper 15, which is mounted on the carrier part, are a component of the brake system. Through the wheel carrier an articulated shaft, which drives the vehicle wheel 13, is guided, wherein on the constant velocity joint 9 of the articulated shaft an also not shown central screw is screwed with which the wheel bearing 12 is clamped via the wheel hub 5 and the constant velocity joint 9.

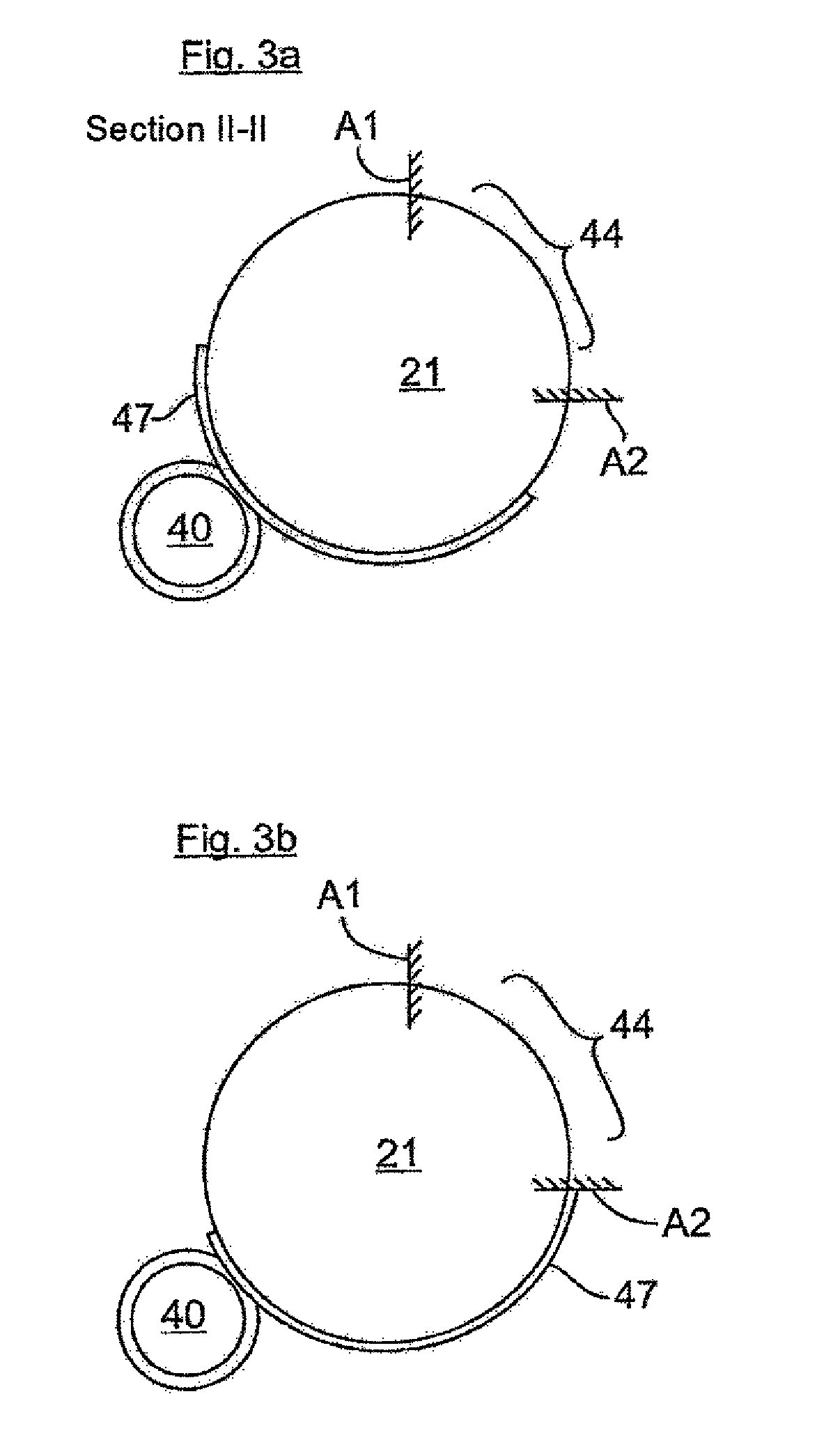

[0031]The wheel carrier also has a guide part 17 on which in FIG. 1 exemplarily a control arm 19 of the wheel suspension is articulately connected. Between the carrier part 3 and the guide part 17 two rotary parts 21, 23 are pr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap