Infrared-ray absorption film

a technology of infrared radiation and absorption film, which is applied in the direction of thermoelectric devices, optical radiation measurement, instruments, etc., can solve the problems of high cost and the inability of gold black film to be free from high cost, and achieve the effects of low reflection factor, increased irregular reflection, and high absorption ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

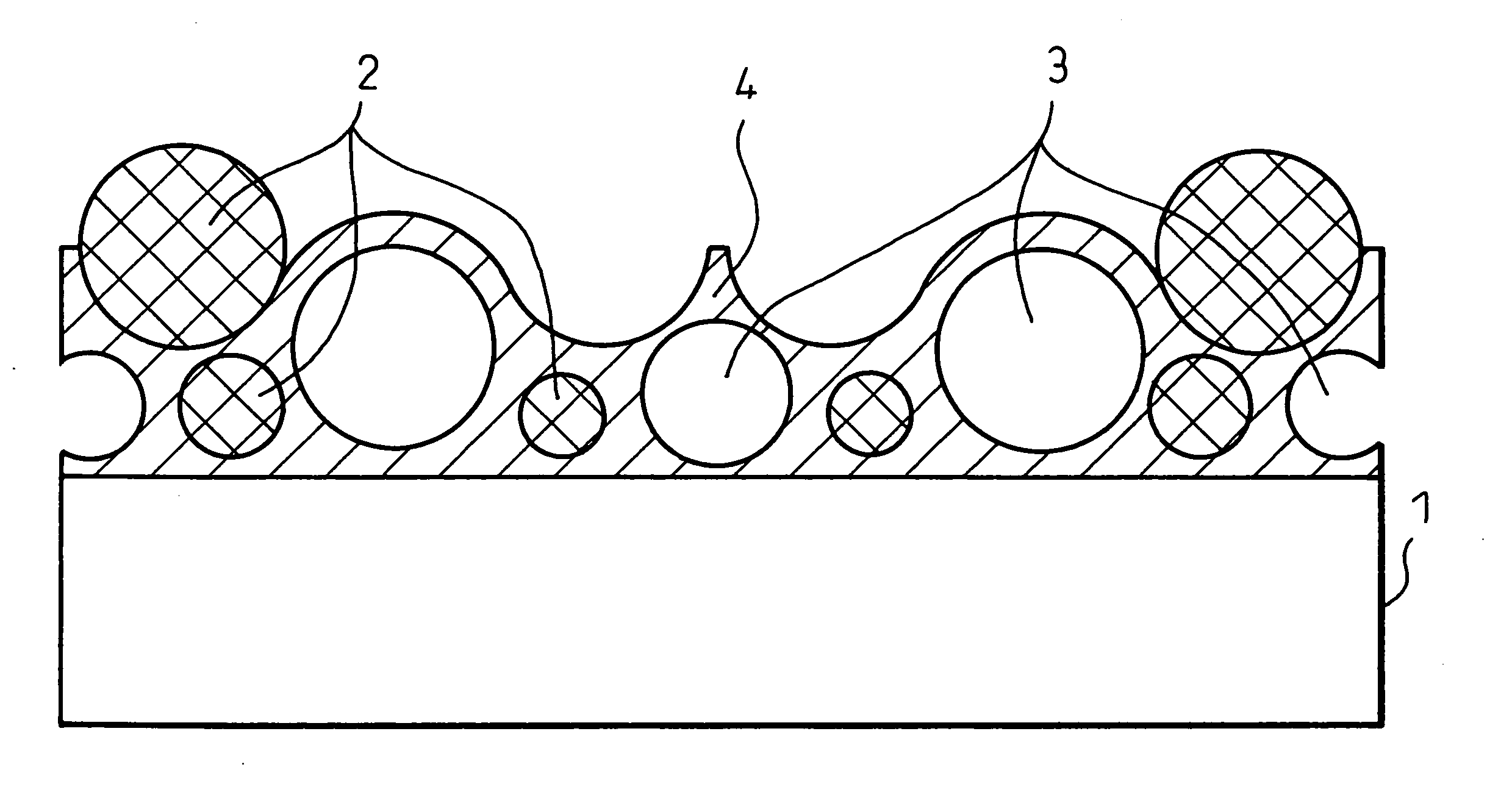

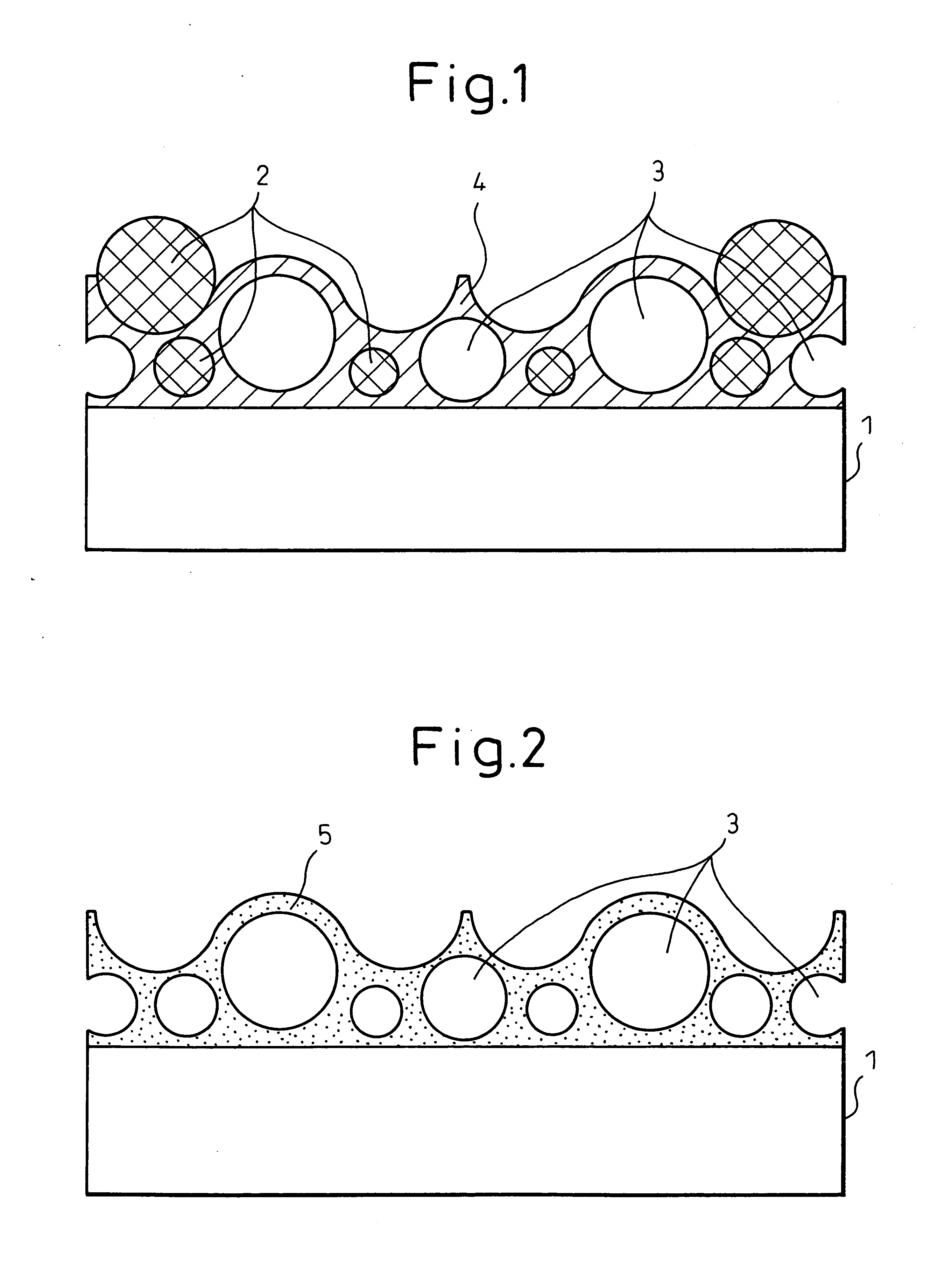

[0010] An infrared-ray absorption film according to the invention uses a porous material. The pore size of this porous material is suitably within the range of several hundreds of nm to several μm. Such a porous material is formed of carbon or a meso-porous (having a pore diameter of 2 to 50 nm) material.

[0011] The infrared-ray absorption film using the porous material is suitably formed by the steps of applying a porous material precursor solution onto a substrate by ink jet printing, etc, and then conducting sintering. Examples of such a porous material precursor solution are a solution prepared by dispersing carbon particles and resin particles in a dispersion medium and a solution prepared by dispersing resin particles in a dispersion medium containing a meso-porous skeletal material (such as a metal alkoxide), a surface active agent and water.

[0012] The pore size of the porous material in the invention is decided by burn-out of the resin particles described above.

[0013] For exa

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap