Angled cooling divider wall in blade attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

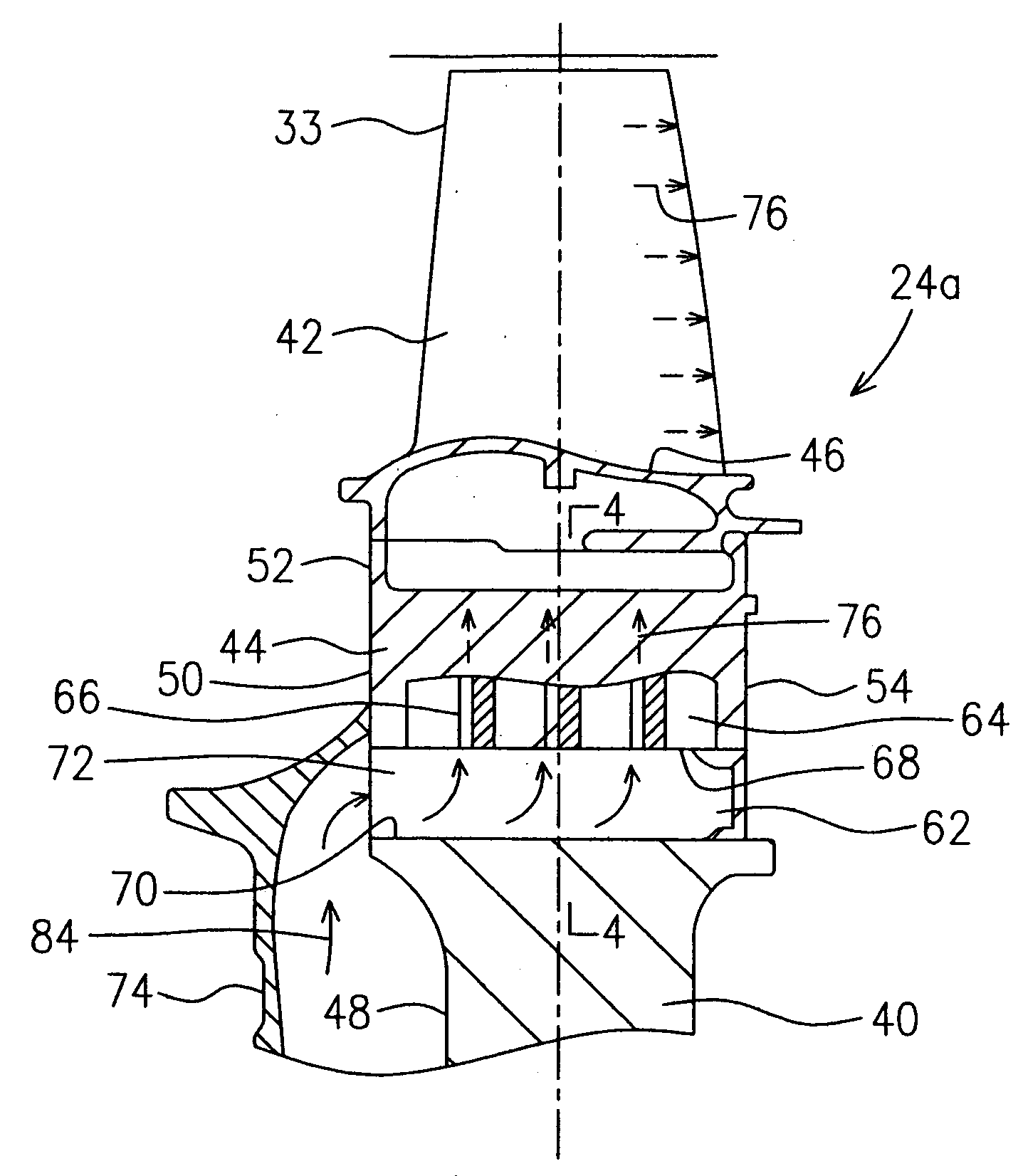

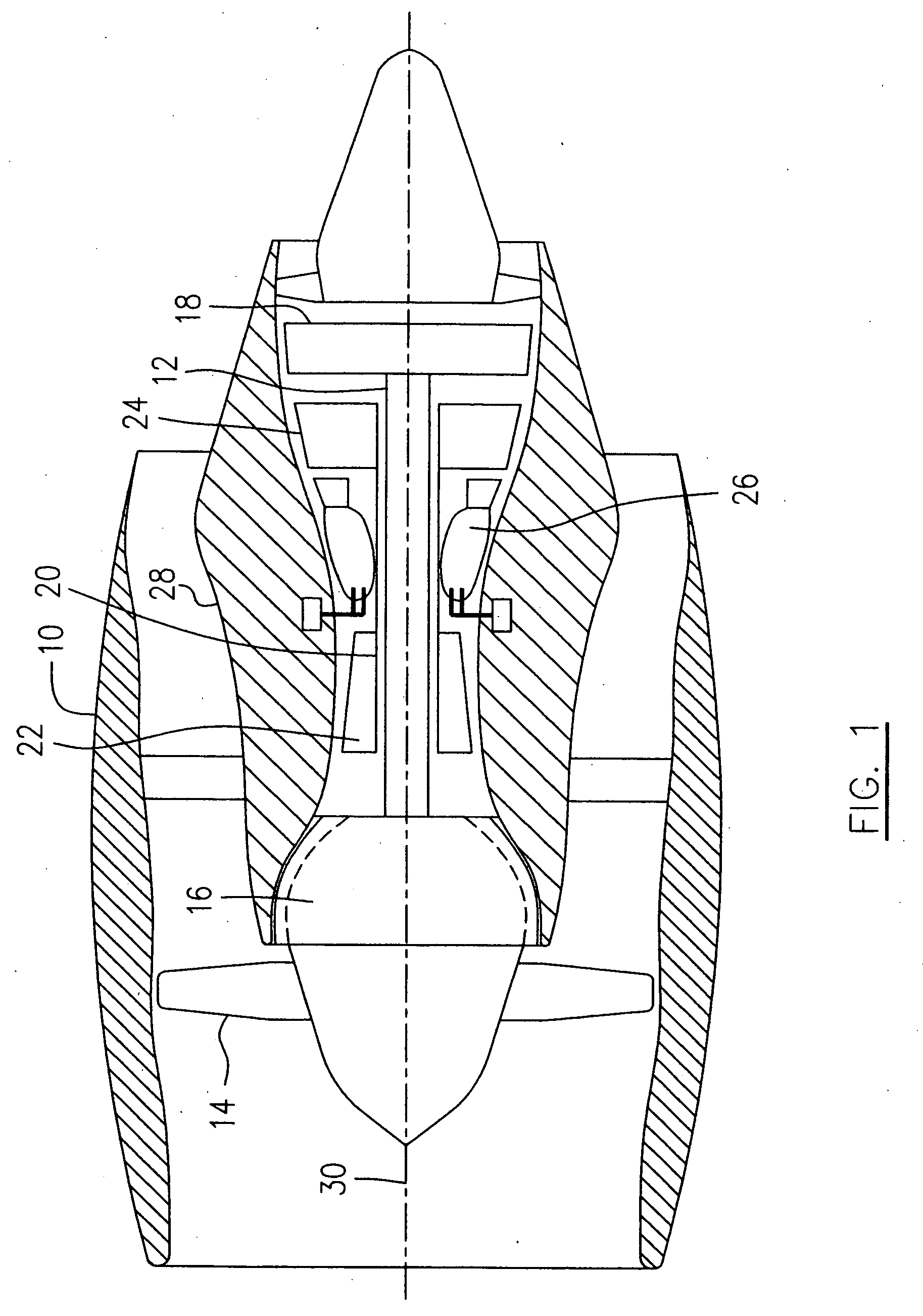

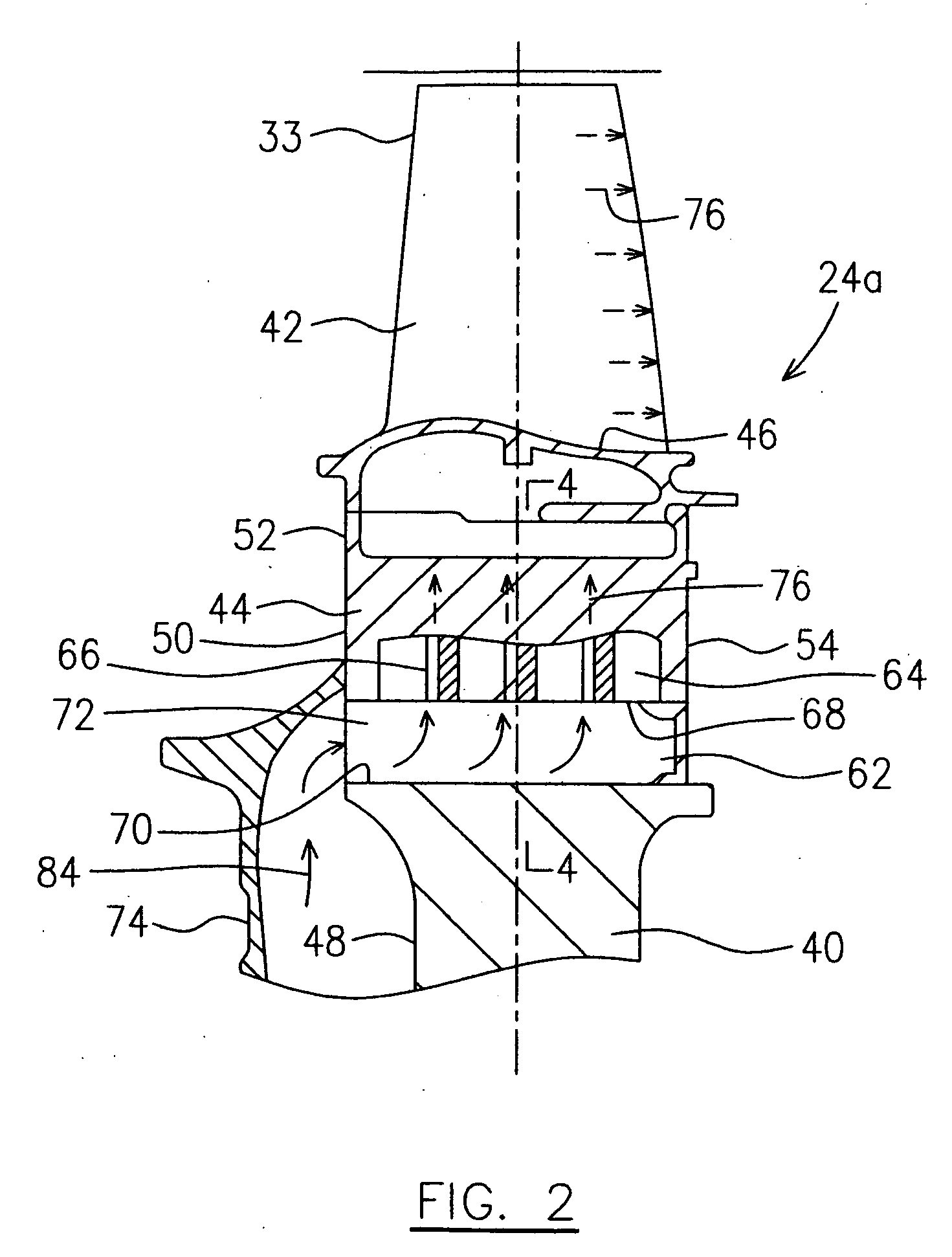

[0018] A turbofan engine illustrated schematically in FIG. 1, presented as an example of the application of the present invention, includes a housing or nacelle 10, a low pressure spool assembly seen generally at 12 which includes a fan 14, a low pressure compressor 16 and a low pressure turbine 18, a high pressure spool assembly seen generally at 20 which includes a high pressure compressor 22 and a high pressure turbine 24. A core casing 28 surrounds the low and high pressure spool assemblies 12 and 20 to define a main fluid path (not indicated) therethrough. In the main fluid path there is provide a combustor seen generally at 26 with fuel injecting means (not indicated) to constitute a gas generator section. The compressors 16 and 22 drive a main airflow (not indicated) along the main fluid path and provide bleed airflow as a cooling air source for cooling the combustor 26 as well as the turbines 18 and 24.

[0019] It should be noted that similar components of the different embodime

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap