Color Filter

a color filter and color film technology, applied in the field of color filters, can solve the problems of uneven gap and breakage of the ito film formed on the color filter, and achieve the effect of reducing the uneven gap with respect to the opposite side of the substra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

1. First Embodiment

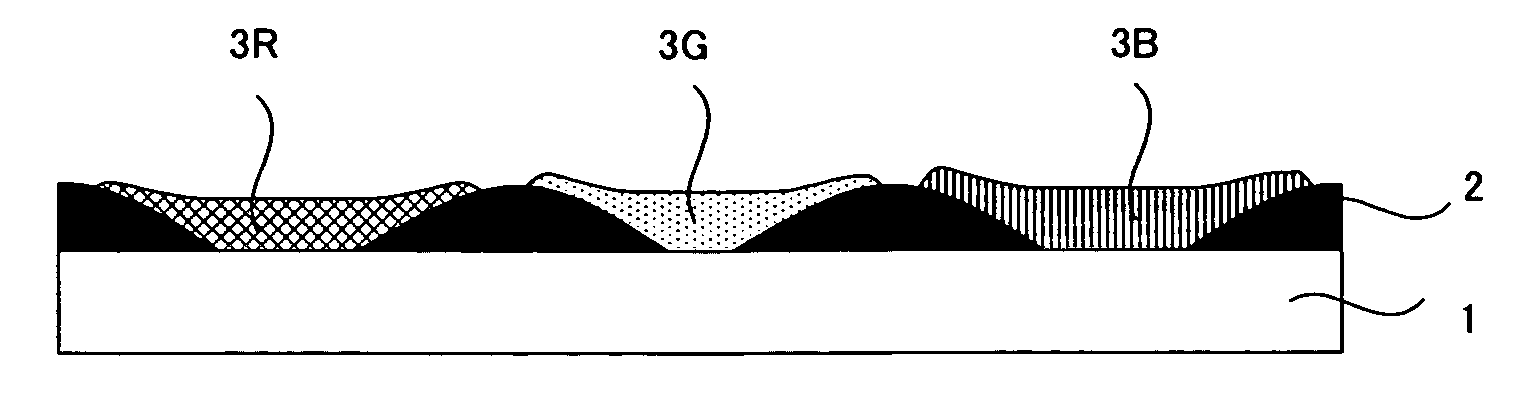

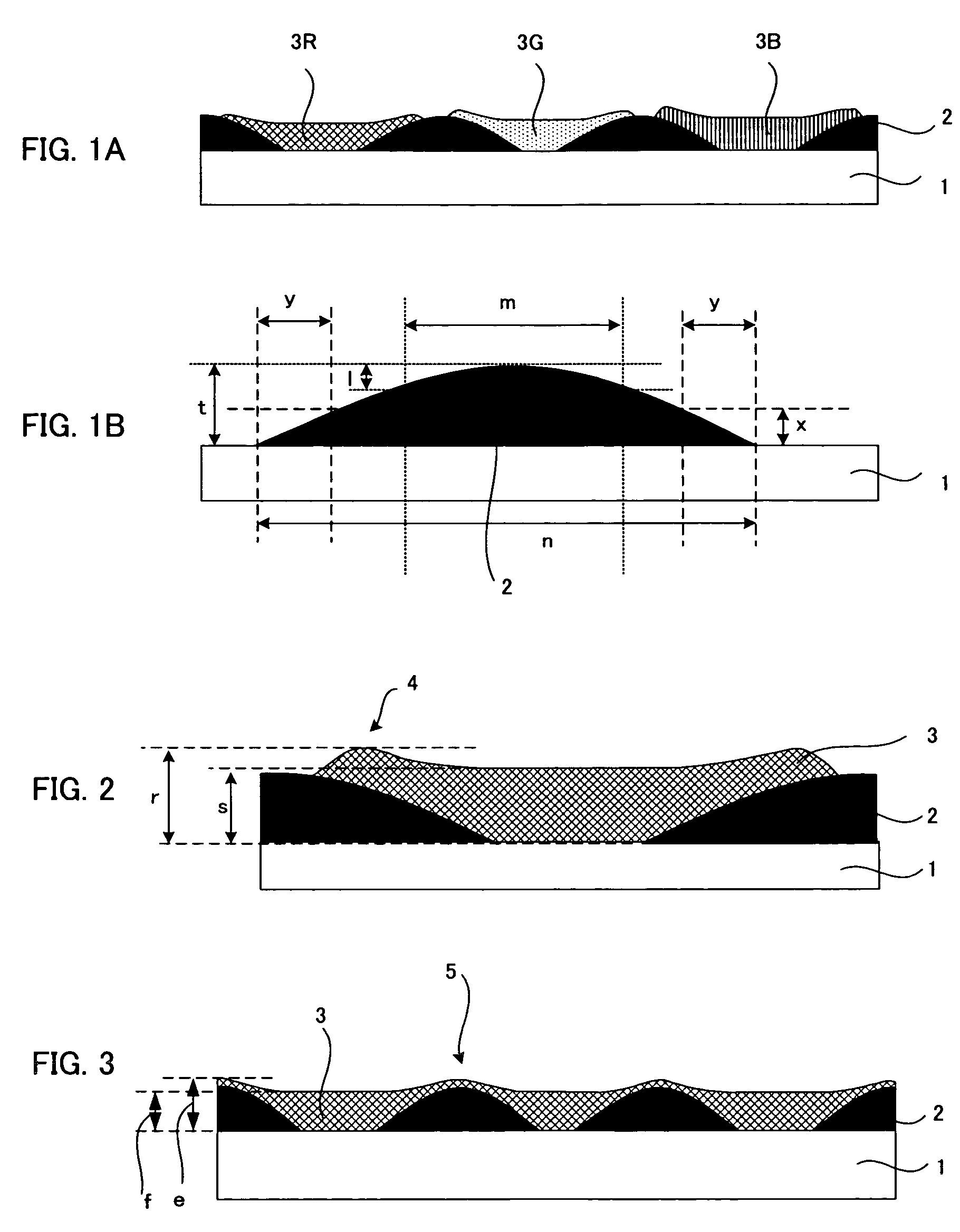

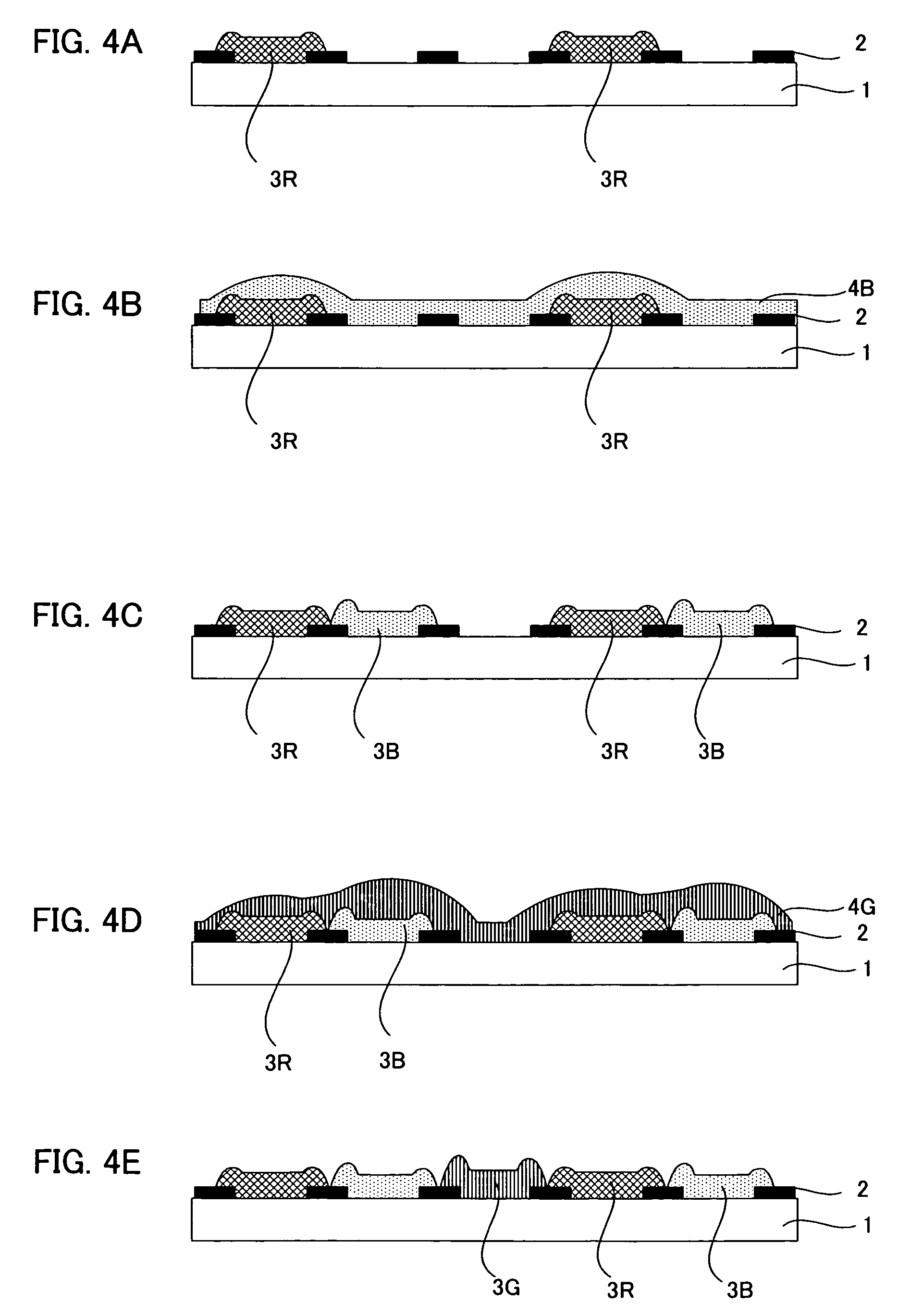

[0026] First, a first embodiment of the color filter of the present invention will be explained. The first embodiment of the color filter of the present invention is a color filter comprising: a transparent substrate; a light shielding part formed on the transparent substrate and contains at least a light shielding material and a resin; and a colored layer formed in the opening part of the light shielding part on the transparent substrate to cover a part of the light shielding part, characterized in that the width of the thick film region, 85% of more of the maximum film thickness of the light shielding part and disposed in the central part of the light shielding part, is in a predetermined range with respect to the light shielding part line width, and the width of each of the thin film regions, 50% or less of the maximum film thickness of the light shielding part and disposed on the both side parts of the light shielding part, is in a predetermined range with respec

second embodiment

2. Second Embodiment

[0056] Next, a second embodiment of the color filter of the present invention will be explained. The second embodiment of the color filter of the present invention is a color filter comprising: a transparent substrate; a light shielding part formed on the transparent substrate and contains at least a light shielding material and a resin; a colored layer formed in the opening part of the light shielding part on the transparent substrate to cover a part of the light shielding part; and a crossing part with the colored layer and the light shielding part crossing each other such that the colored layer covers the light shielding part, characterized in that the difference between the maximum film thickness of the crossing part and the film thickness of the central part of the colored layer formed in the opening part of the light shielding part is in a predetermined range.

[0057] The above-mentioned crossing part denotes a region with the colored layer and the light shield

examples

[0064] Hereinafter, with reference to the example and the comparative example, the present invention will be explained further specifically.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap