Mode strut and divergent flap interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

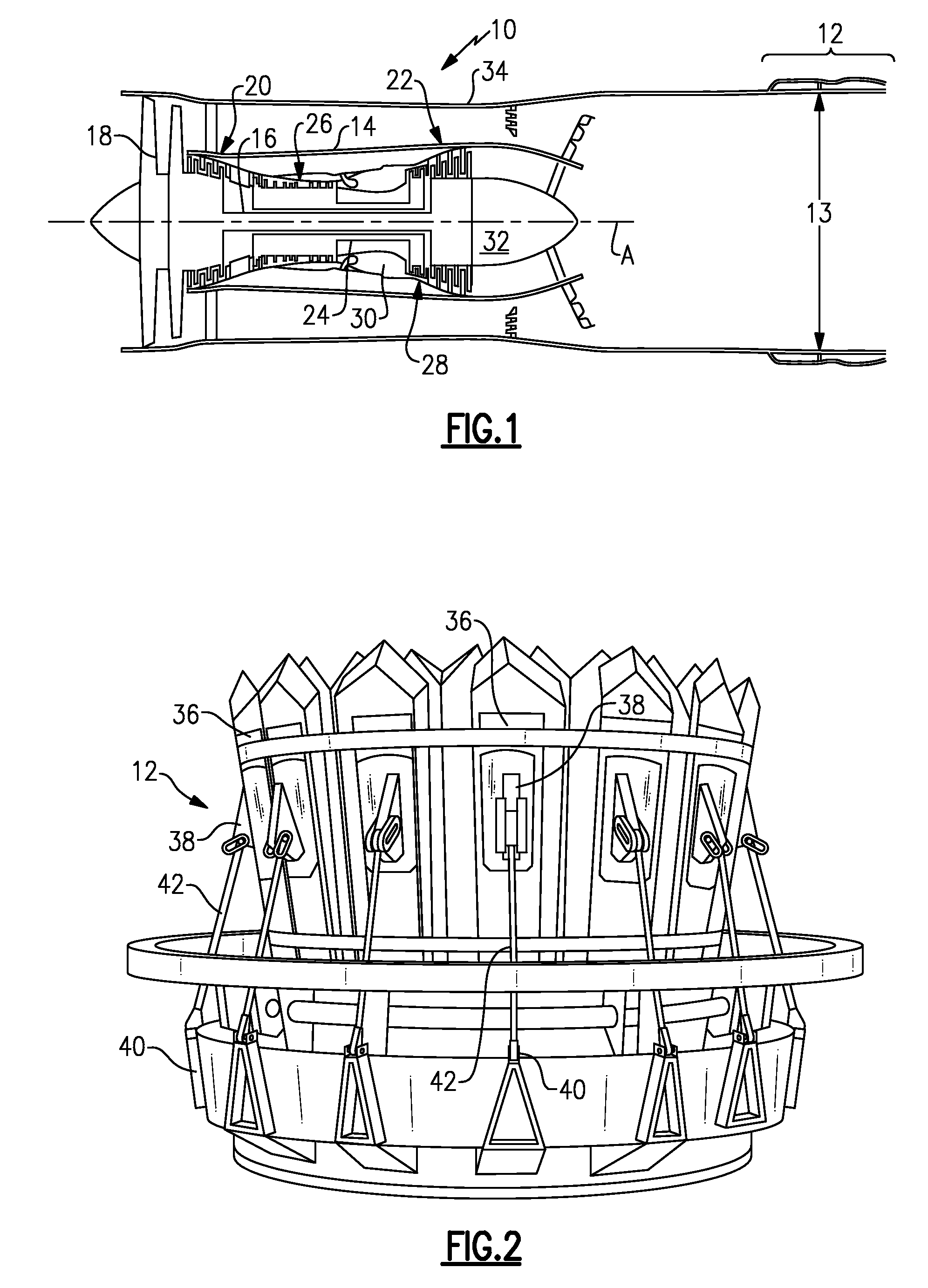

[0014]A turbofan engine 10 is shown schematically in FIG. 1. As known, a fan section moves air and rotates about an axis A. A compressor section, a combustion section, and a turbine section are also centered on the axis A. FIG. 1 is a highly schematic view, however, it does show the main components of the gas turbine engine. Further, while a particular type of gas turbine engine is illustrated in this figure, it should be understood that the claim scope extends to other types of gas turbine engines.

[0015]The engine 10 includes an exhaust nozzle 12 for varying the nozzle exit area 13 to achieve a desired thrust. The engine 10 includes a core 14 housing a low spool 16. A fan 18, low pressure compressor 20 and low pressure turbine 22 are mounted on the low spool 16. A high spool 24 is arranged coaxially relative to the low spool 16. A high pressure compressor 26 and high pressure turbine 28 are mounted on the high spool 24. A combustor 30 is arranged between the high pressure compressor 2

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap